Universal length grading screening equipment

A graded screening, general-purpose technology, applied in the direction of classification, solid separation, chemical instruments and methods, etc., to achieve the effect of fast screening speed and saving screening time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

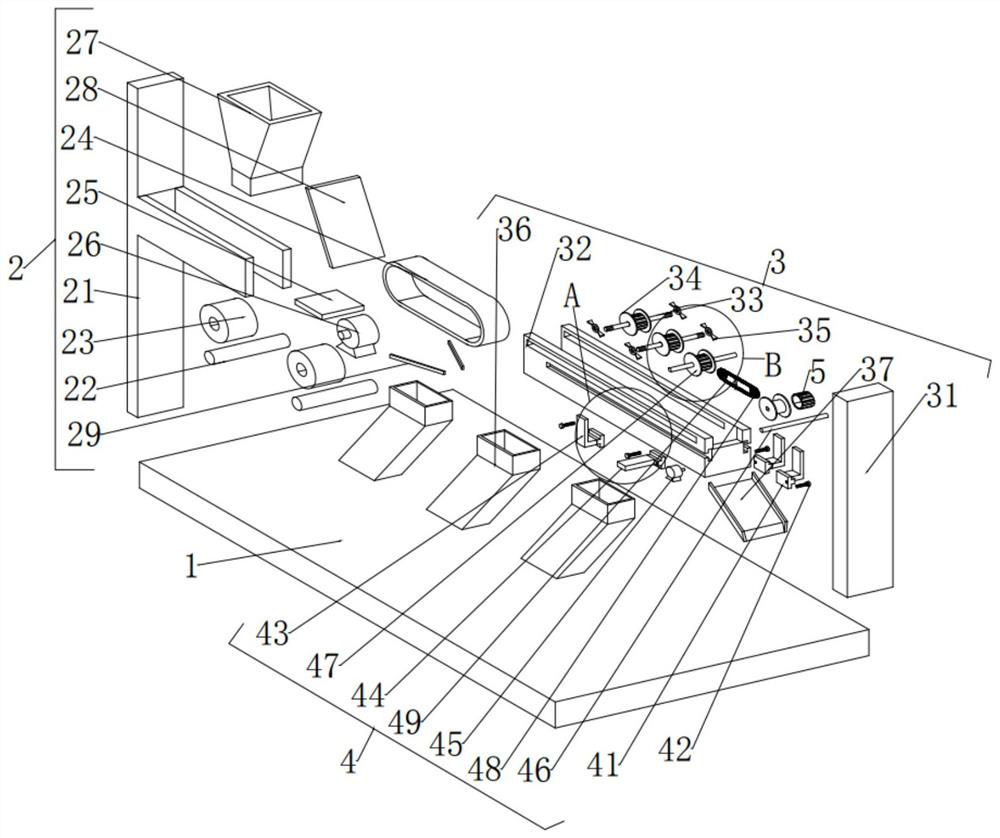

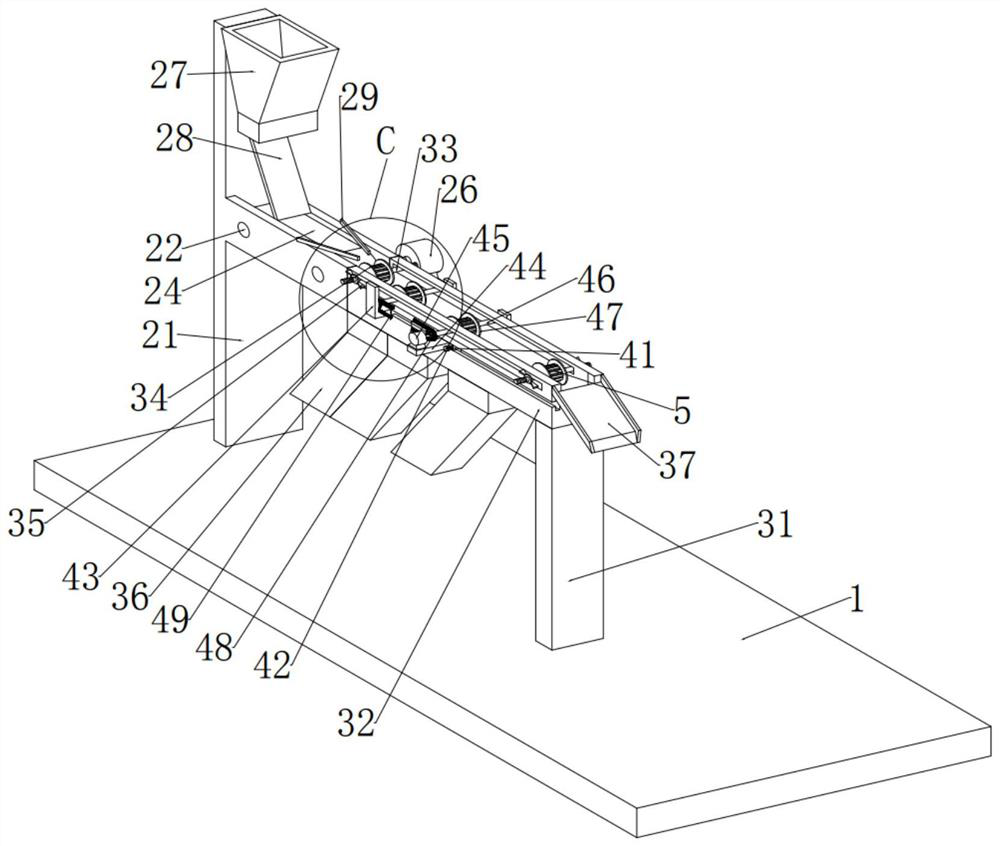

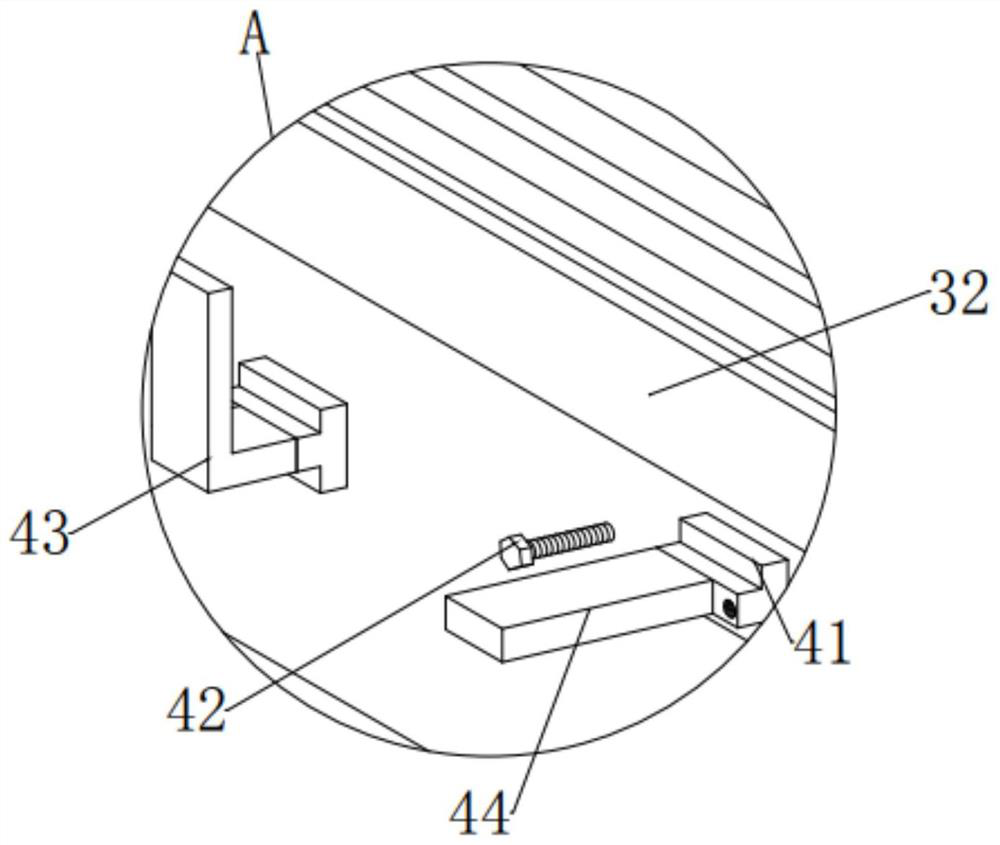

[0045] Embodiment: according to specification Figure 1-5 It can be seen that, firstly, through the stable support of the base 1 equipment, a plurality of mixed rods of different lengths can be placed in the material box 27 on the feeding frame 21 in the unloading structure 2, and the workpieces are all slid out through the material guide plate 28 to On the conveyor belt 24, by driving the first motor 26 on the first bearing plate 25, one of the first shafts 22 is driven to rotate, so that the conveyor belt 24 is forced to reciprocate on the two rollers 23, and the workpiece is conveyed from the left side To the right side, and focus on the middle area by means of the limit of the guide rod 29;

[0046] Secondly, the workpiece can be moved into the sorting structure 3 by means of the power of the conveyor belt 24, on the first guide wheel 34 in the left end of the mounting frame 32 supported by the bracket 31, and then increase the friction force through the rubber ring 5, so ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com