Preparation method and equipment of graphene oxide or graphite oxide

A technology of graphene and graphite, which is applied in the field of graphene, can solve the problems of preparation efficiency research, long purification time, and no solution to the preparation time, so as to avoid the effect of clogging equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] see image 3 , this example shows a preferred embodiment of the apparatus for producing graphene oxide or graphite oxide according to the present invention. The equipment comprises a reactor 1, a first transfer device 10, a purifier 2, a second transfer device 20, a first purifier 11, a third transfer device 30, a first collector 12 and a fourth transfer device 40,

[0068] Wherein, the first transfer device 10 is arranged between the reactor 1 and the purifier 2, and is connected with the reactor and the purifier, and is used to send all the products discharged from the reactor into the purifier; the second transfer device 20 is arranged at Between the purifier 2 and the first purifier 11, and connected with the purifier 2 and the first purifier 11, for separating graphene oxide or graphite oxide slurry in the purifier 2 into the first purifier 11; The third transfer device 30 is arranged between the first purifier 11 and the first collector 12, and is used to send th...

Embodiment 2

[0074] see Figure 4 , this example shows a preferred embodiment of the apparatus for producing graphene oxide or graphite oxide according to the present invention. The structure of each device is the same, the difference lies in the combination of each device in the equipment. Such as Figure 4 As shown, the equipment shown in this embodiment includes: a reactor 1, a first transfer device 10, a purifier 2, a second transfer device 20, a first purifier 11, a third transfer device 30, a first collector 12, a second transfer device Four transfer device 40, second purifier 13, fifth transfer device 50, second collector 14, sixth transfer device 60, third purifier 15, seventh transfer device 70, third collector 16, eighth transfer device 80 and the fourth purifier 17.

[0075] Wherein, the first transfer device 10 is arranged between the reactor 1 and the purifier 2, and is connected with the reactor and the purifier, and is used to send all the products discharged from the rea...

Embodiment 3

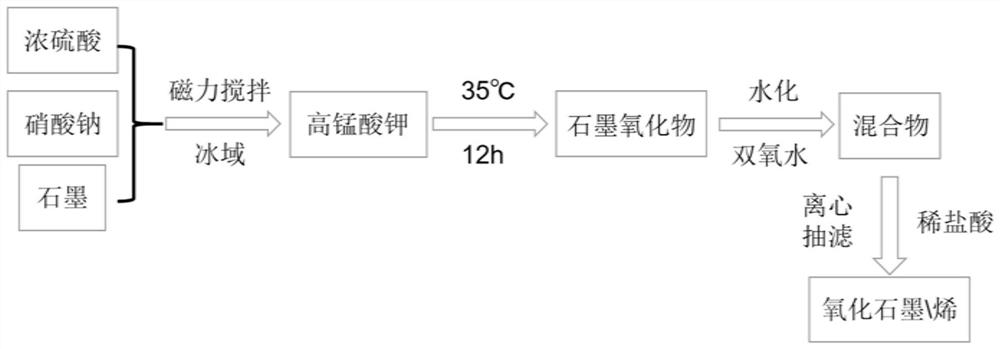

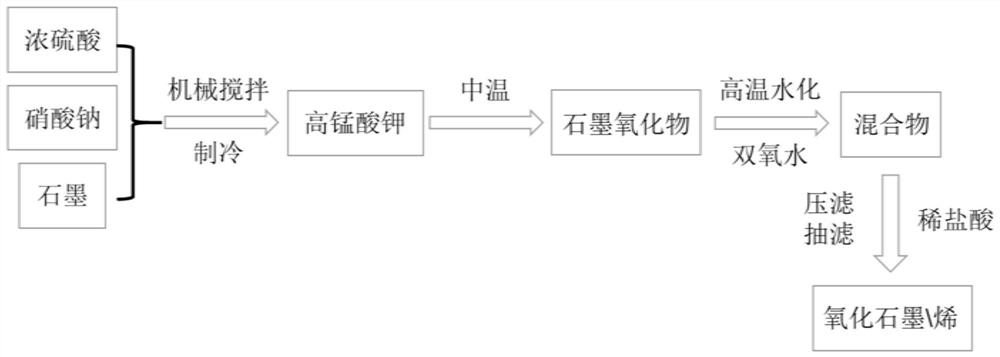

[0077] A kind of preparation method of graphene oxide or graphite, adopt the equipment shown in embodiment 1, be specially:

[0078] First add 98wt% concentrated sulfuric acid in the reactor, graphite and potassium permanganate are added to reactor 1 in turn, graphite, potassium permanganate: 98wt% concentrated sulfuric acid is prepared according to 1g:4g:30mL;

[0079] After adding concentrated sulfuric acid, graphite and potassium permanganate, the temperature of reactor 1 was raised to 40°C, and the reaction was continued for 5 hours;

[0080] After the reaction time is up, adjust the reaction temperature to 85°C by adding water, and continue the reaction for 5h;

[0081] The reacted material passes through image 3 equipment, in configuration 5 for 5 washes.

[0082] Specifically, the method for preparing graphene oxide includes: using the equipment described in Example 1 to produce according to the following process:

[0083] 1) Put concentrated sulfuric acid, graphite...

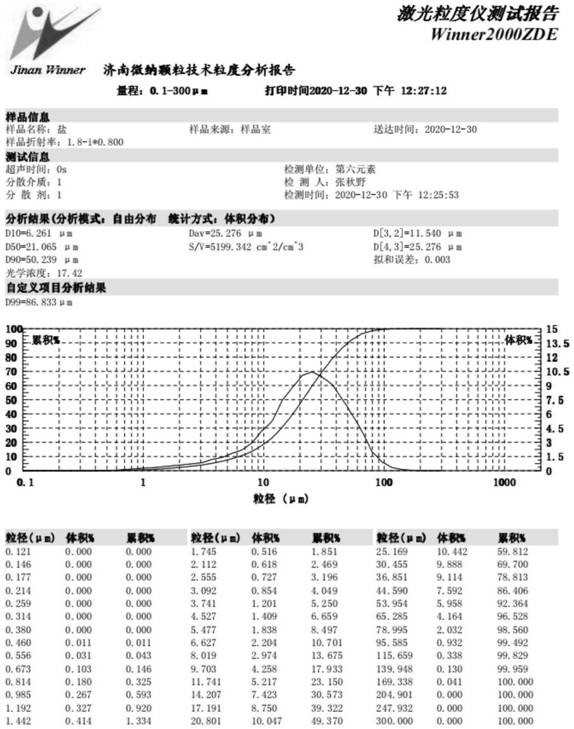

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com