Drilling machine electric control system power point temperature rise stepped grading automatic early warning method

A technology of automatic early warning and electronic control system, which is applied in the direction of drilling automatic control system, general control system, control/adjustment system, etc., can solve the problems of low automation level and low precision rate, and achieve high automation level and novel thinking , Put an end to the effect of human error factors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

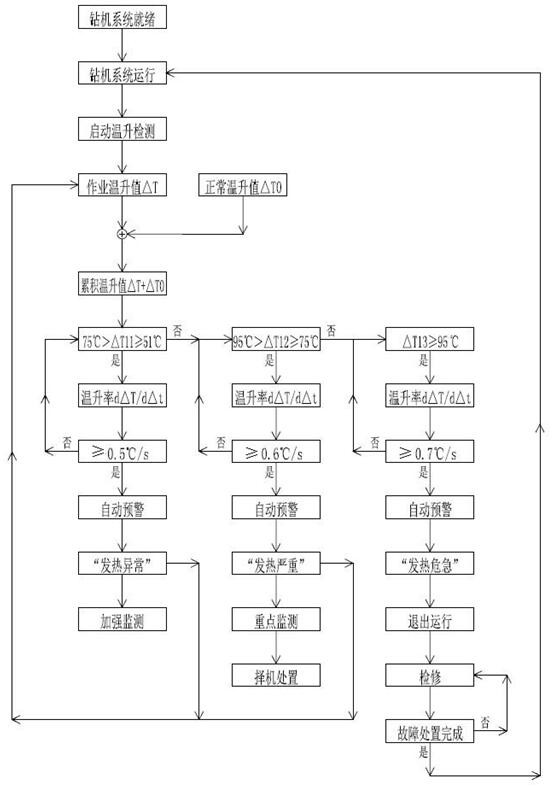

[0020] Such as figure 1 As shown, due to different power points, the temperature rise ΔT1 range of the power point is different, so the range of values taken in this embodiment is only for further elaboration and explanation of the present invention.

[0021] In the present invention, a temperature sensor is firstly installed at the power point of the electric control system of the drilling rig, and the temperature of the power point is detected in real time by using the temperature sensor, and the detection signal is sent to the PLC, and then the temperature rise step in the system is set in the PLC system: at normal temperature rise On the basis of , when the power point temperature rise, that is, the operating temperature rise value △T1 is between 1 and 25°C, the cumulative temperature rise △T11 = △T0 + △T1 (25°C>△T1≥1°C), 75°C>△T11 ≥51°C, and there is a tendency to continue to rise, and the temperature rise rate (d△T1 / d△t) ≥ 0.5°C / s, defined as "abnormal heating", it sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com