Automobile radiator and production process thereof

A technology of automobile radiator and heat pipe, which is applied in the direction of heat exchanger shell, heat transfer modification, heat exchange equipment, etc. The effect of moving speed and ensuring constant water pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

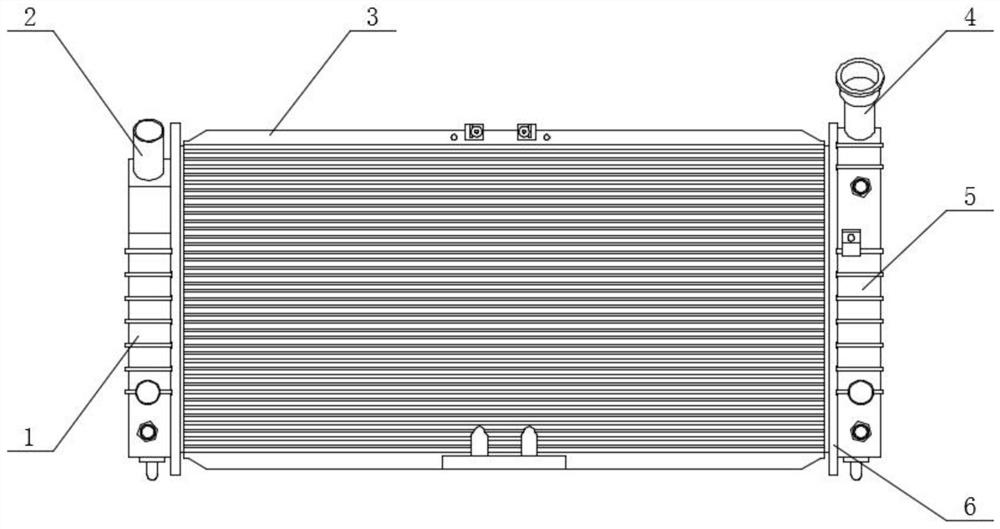

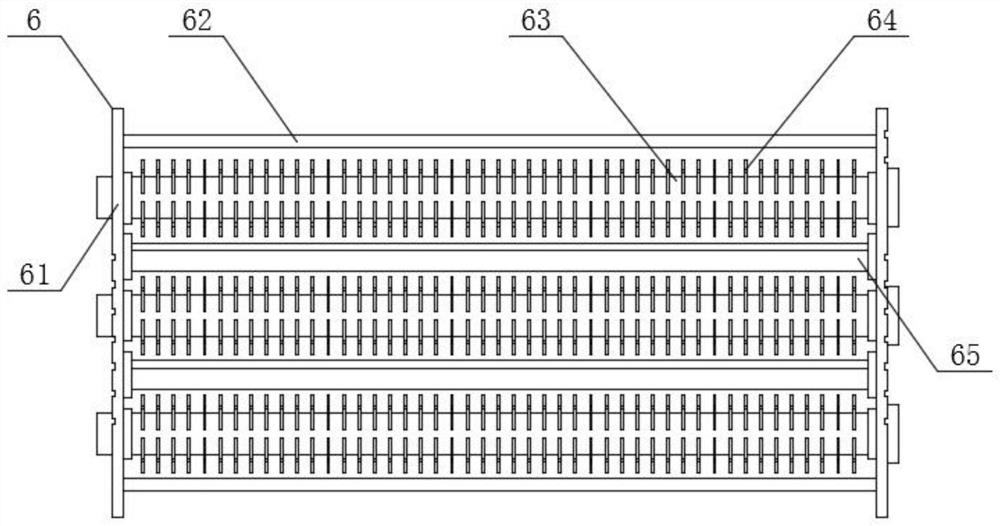

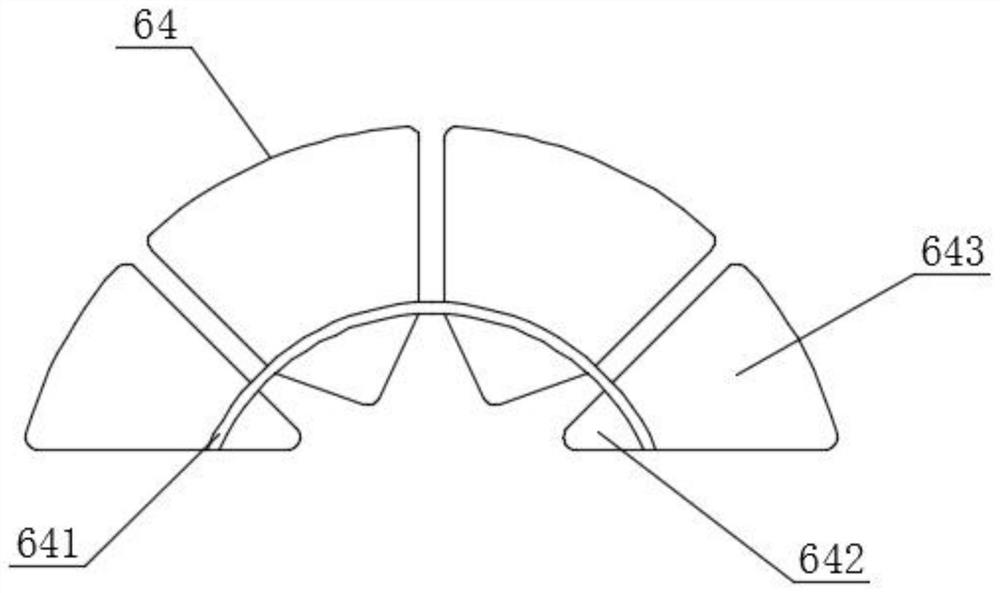

[0028] Such as Figure 1-3 As shown, a kind of automobile radiator comprises water outlet pipe 2, and the lower end of water outlet pipe 2 is fixed with water outlet box 1, and the right end of water outlet box 1 is clamped with heat dissipation pipe 6, and the front end of heat dissipation pipe 6 is fixed with heat dissipation device 3, heat dissipation pipe The right end of 6 is clamped with a water inlet tank 5, and the upper end of the water inlet tank 5 is fixed with a water inlet pipe 4, and the cooling pipe 6 includes a fixed frame 61, and a connecting column 62 is fixed in the middle of the fixed frame 61, and the bottom of the connecting column 62 is on the fixed frame. The middle position of 61 is fixed with connecting pipe 63, and the surface of connecting pipe 63 is welded and fixed with radiating fin 64, and the middle of radiating fin 64 is provided with guiding device 65, and radiating fin 64 comprises radiating fin 643, and the lower end of radiating fin 643 A ...

Embodiment 2

[0031] Such as Figure 1-4 As shown, a kind of automobile radiator comprises water outlet pipe 2, and the lower end of water outlet pipe 2 is fixed with water outlet box 1, and the right end of water outlet box 1 is clamped with heat dissipation pipe 6, and the front end of heat dissipation pipe 6 is fixed with heat dissipation device 3, heat dissipation pipe The right end of 6 is clamped with a water inlet tank 5, and the upper end of the water inlet tank 5 is fixed with a water inlet pipe 4, and the cooling pipe 6 includes a fixed frame 61, and a connecting column 62 is fixed in the middle of the fixed frame 61, and the bottom of the connecting column 62 is on the fixed frame. The middle position of 61 is fixed with connecting pipe 63, and the surface of connecting pipe 63 is welded and fixed with cooling fin 64, and the middle of cooling fin 64 is provided with guiding device 65, and guiding device 65 comprises fixing plate 651, and the front end of fixing plate 651 is welde...

Embodiment 3

[0034] Such as Figure 1-5 As shown, a kind of automobile radiator comprises water outlet pipe 2, and the lower end of water outlet pipe 2 is fixed with water outlet box 1, and the right end of water outlet box 1 is clamped with heat dissipation pipe 6, and the front end of heat dissipation pipe 6 is fixed with heat dissipation device 3, heat dissipation pipe The right end of 6 is clamped with water inlet box 5, and the upper end of water inlet box 5 is fixed with water inlet pipe 4, and water inlet pipe 4 comprises pipe body 41, and the inner surface of pipe body 41 is fixed with dividing plate 42.

[0035] The water inlet pipe 4 introduces the water flow with high external temperature. The water flow moves along the pipe body 41 and is divided into three water flows separated by the partition plate 42. The three flows enter the three chambers inside the water inlet tank 5 along the pipe, thereby entering Inside the three connecting pipes 63, the water flow can be evenly divi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com