Dustproof air pressure follow-up control valve for aero-engine lubrication system

A technology of aero-engine and lubrication system, which is applied in the direction of engine lubrication, lubricating oil control valve, engine components, etc., to achieve the effect of simple structure, good maintainability and strong interface versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] In order to make the purpose, technical solution and advantages of the application more clear, the technical solution in the embodiment of the application will be described in more detail below in conjunction with the drawings in the embodiment of the application.

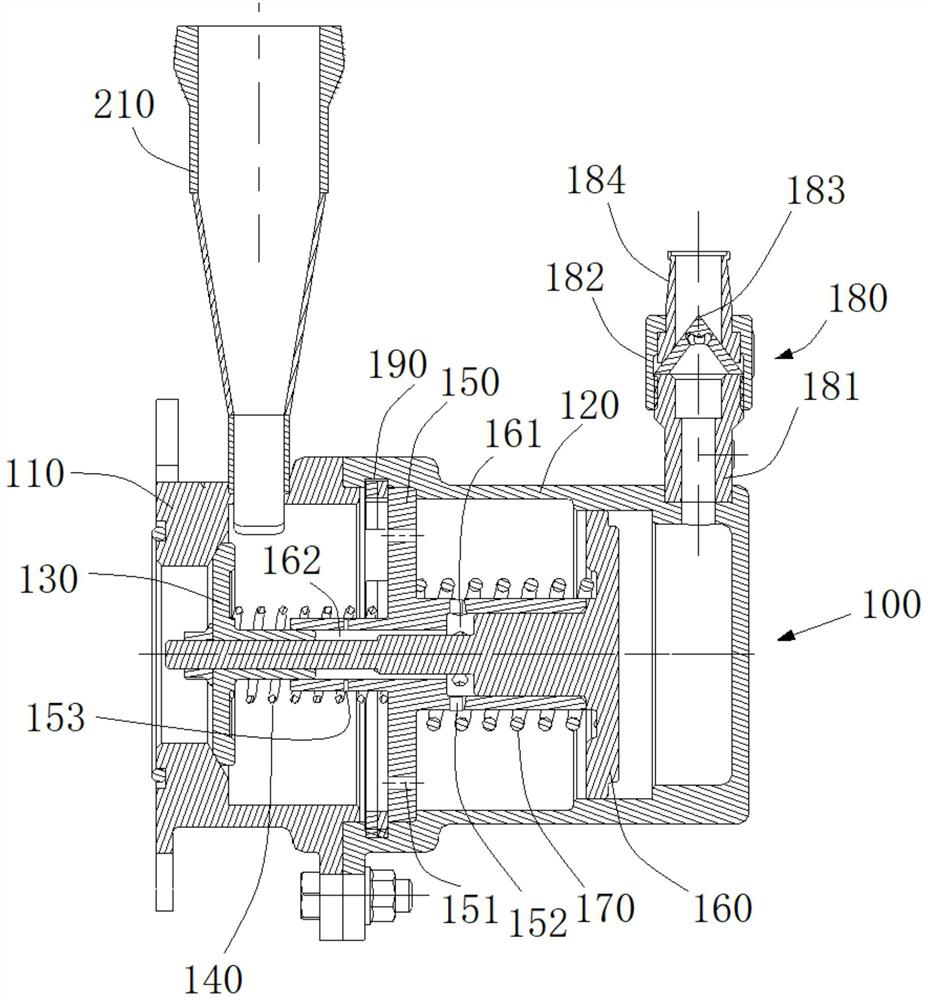

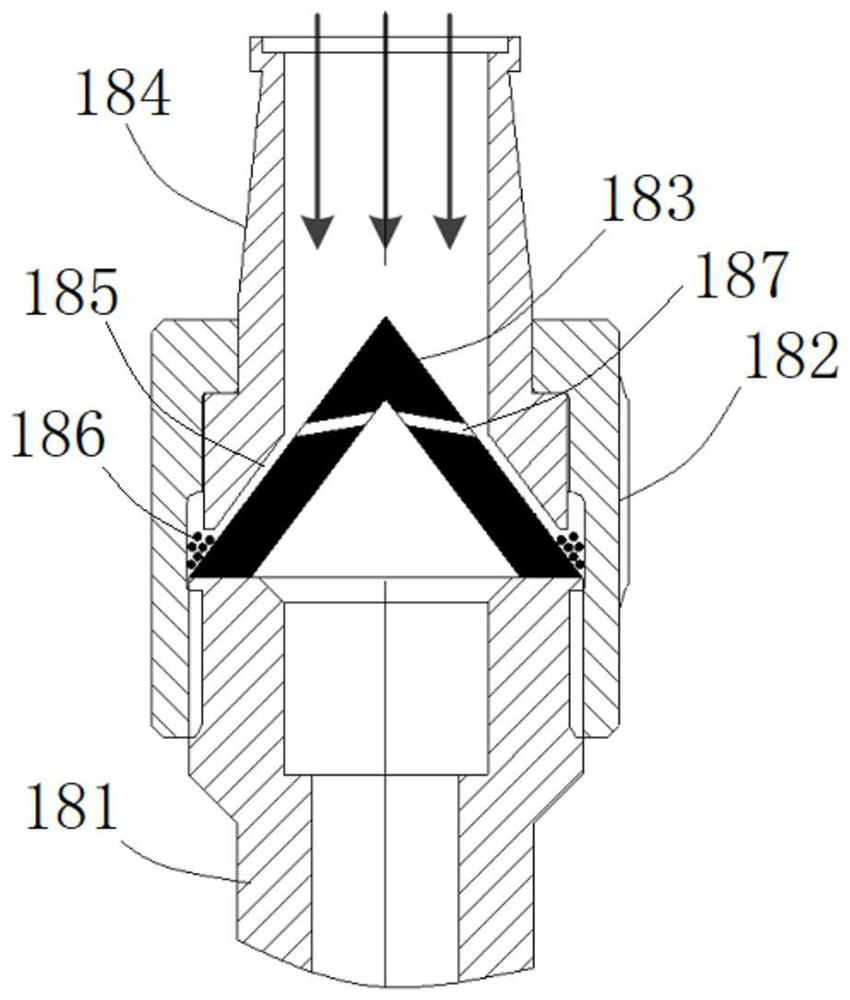

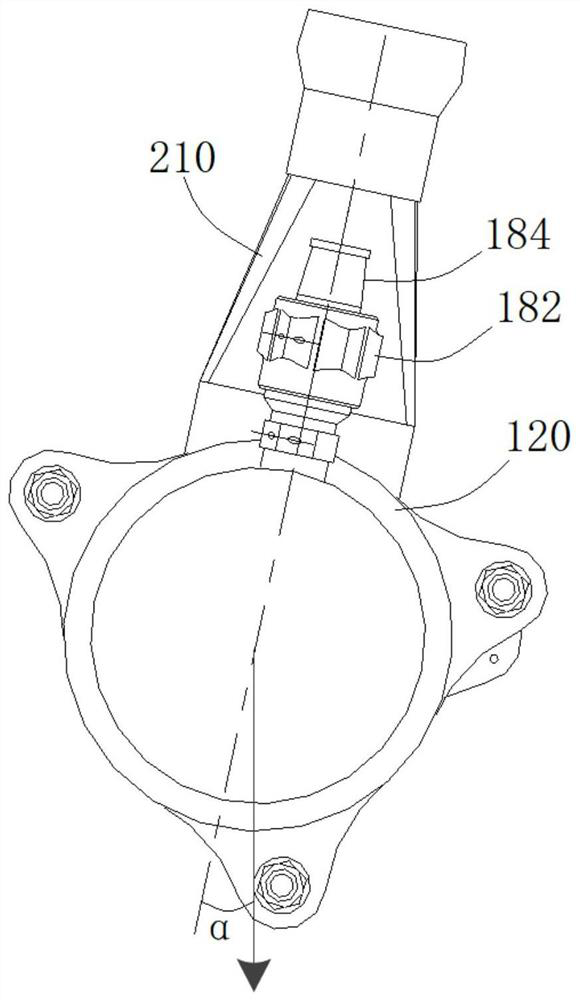

[0055] Such as Figure 1 to Figure 5 As shown, the present application provides a dust-proof aeroengine lubrication system air pressure servo control valve 100, which mainly includes a mounting seat 110, a control valve housing 120, a conical valve body 130, a conical valve spring 140, a valve guide Device 150, control valve body 160, control valve spring 170 and dust removal assembly 180.

[0056] The left side of the installation seat 110 has a control chamber inlet, and its upper side has an exhaust port, the control chamber inlet is used to connect with the control chamber structure 220 , and the exhaust port is used to connect with the exhaust pipeline 210 .

[0057] The control valve housing 120 is fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com