Preparation method of planar TEM sample

A sample and planar technology, applied in the field of planar TEM sample preparation, can solve the problems of reducing TEM test rate and efficiency, spending time and energy, increasing sample preparation time and cost, etc., to improve the preparation success rate and detection efficiency, reduce Production cost and the effect of shortening the production time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

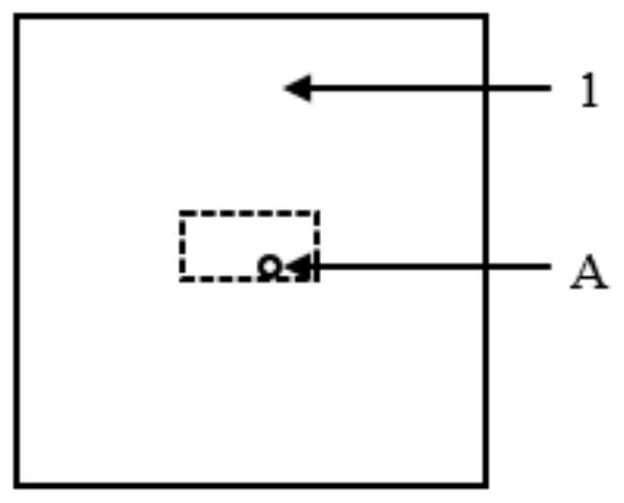

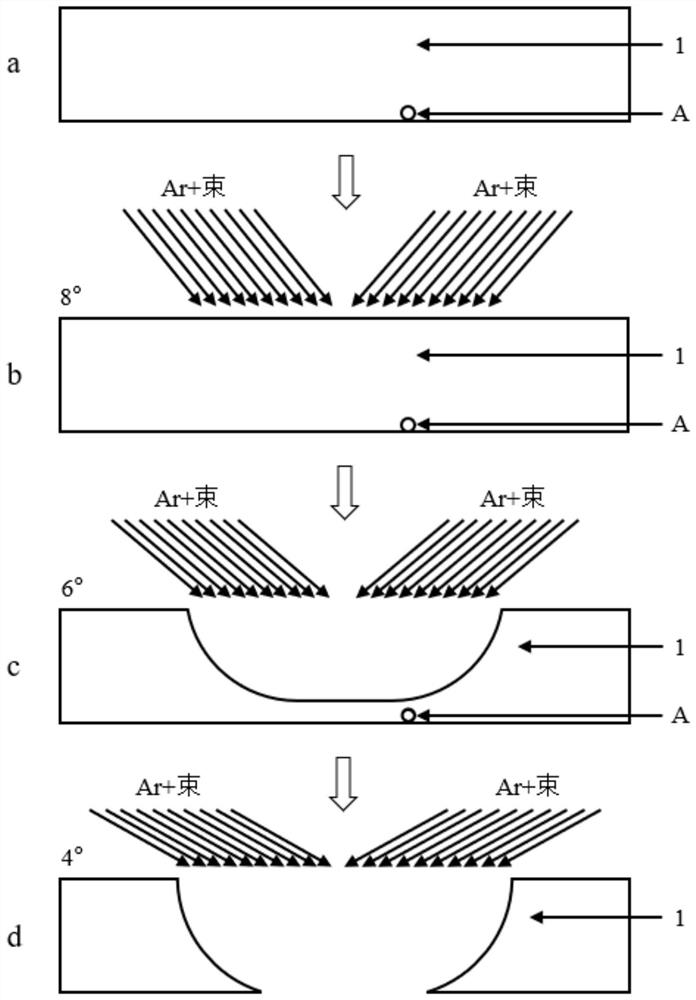

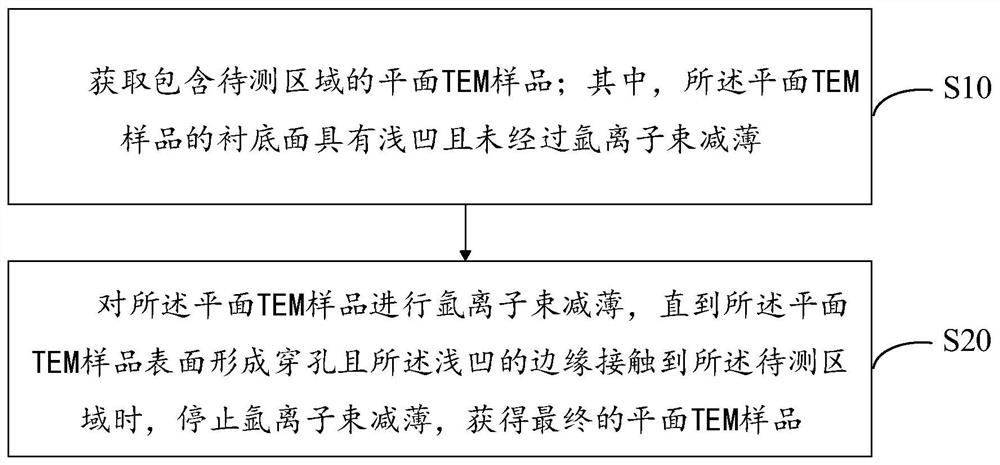

[0036] see image 3 - Figure 7 , a method for preparing a planar TEM sample according to an embodiment of the present invention, at least including the following steps:

[0037] S10. Obtain a planar TEM sample including a region to be measured; wherein, the substrate surface of the planar TEM sample has a shallow concave;

[0038] It should be noted that in the observation experiment of the transmission electron microscope, the quality of the prepared planar sample directly affects the test results, which is a crucial link in the planar TEM test and analysis process. Using transmitted electrons in TEM to obtain information requires that the prepared planar TEM samples must be very thin, that is, the planar samples are transparent to electrons. Enough electron transmission is required to ensure that the illumination intensity on the screen, charge-coupled device, or photographic film is such that an interpretable planar image can be obtained in a reasonable time. For TEM, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com