Melting curve abnormal value processing method and device and electronic equipment

A melting curve and processing method technology, applied in the direction of instrumentation, biostatistics, data visualization, etc., can solve the problem that the melting curve cannot be obtained

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

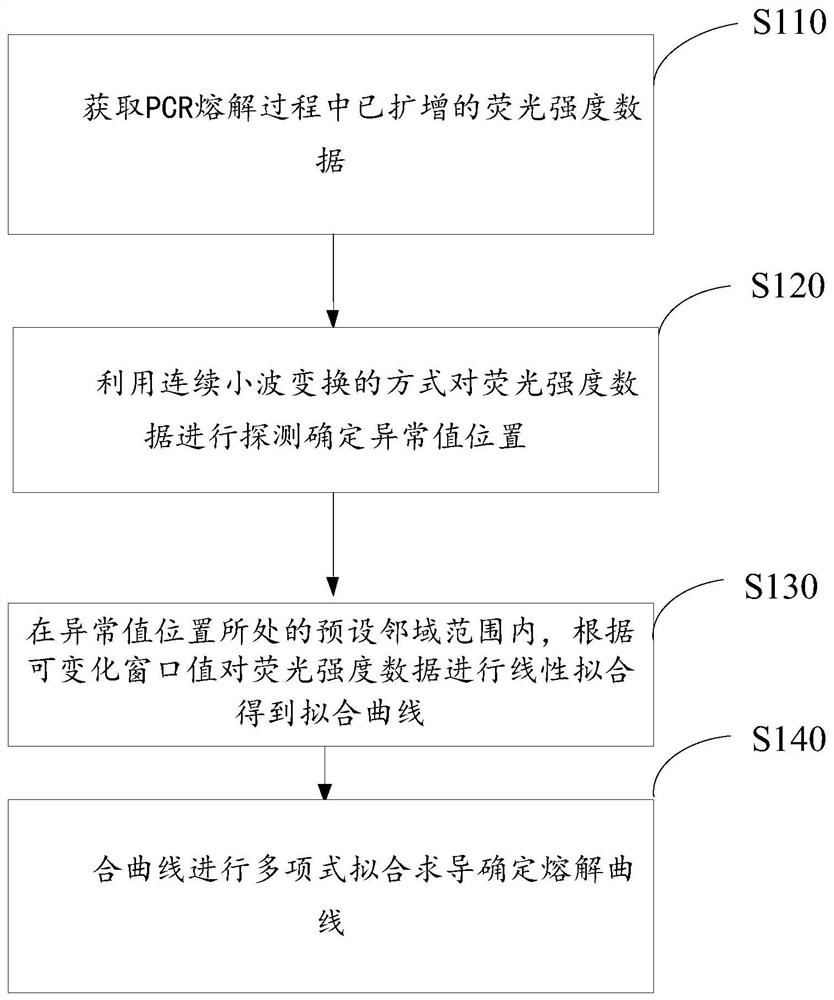

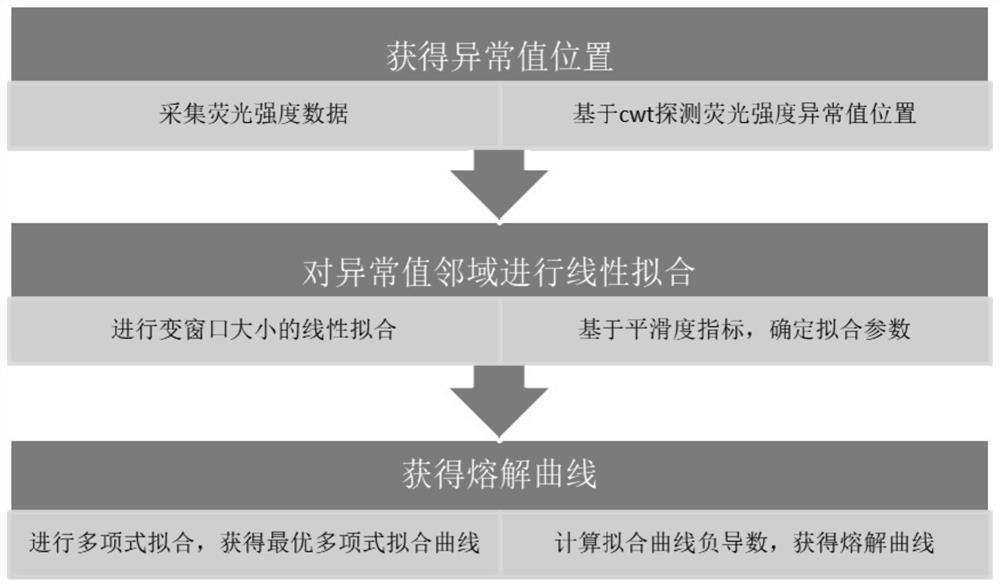

[0054] figure 1 It is a schematic flowchart of a method for processing outliers in melting curves provided in the embodiment of the present application. like figure 1 As shown, the method includes:

[0055] Step S110, acquiring the amplified fluorescence intensity data during the PCR melting process.

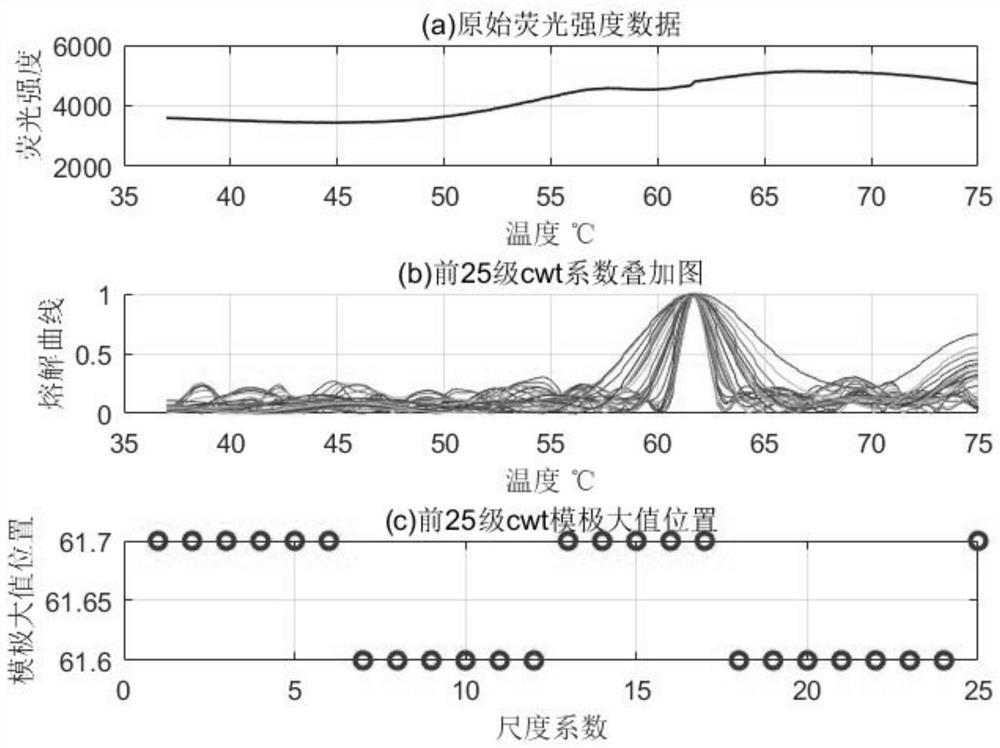

[0056] Step S120 , using continuous wavelet transform to detect the fluorescence intensity data, and determine the position of the outlier.

[0057] Step S130, within the preset neighborhood where the outlier position is located, perform linear fitting on the fluorescence intensity data according to the variable window value to obtain a fitting curve.

[0058] Step S140, performing polynomial fitting and derivation on the fitting curve to determine the melting curve.

[0059] By using the continuous wavelet transform to detect the fluorescence intensity data, the outlier position can be determined. Furthermore, the fluorescence intensity data is linearly fitted according to ...

Embodiment 2

[0102] Image 6 A schematic structural diagram of a melting curve outlier processing device provided in the embodiment of the present application, as shown in Image 6As shown, the amplification curve baseline determination device 600 includes:

[0103] An acquisition module 601, configured to acquire amplified fluorescence intensity data during the PCR melting process;

[0104] A detection module 602, configured to detect the fluorescence intensity data by means of continuous wavelet transform, and determine the position of the outlier;

[0105] A fitting module 603, configured to linearly fit the fluorescence intensity data according to a variable window value within the preset neighborhood where the outlier position is located, to obtain a fitting curve;

[0106] The determining module 604 is configured to perform polynomial fitting and derivation on the fitting curve to determine the melting curve.

Embodiment 3

[0108] An electronic device provided by an embodiment of the present application, such as Figure 7 As shown, the electronic device 700 includes a memory 701 and a processor 702, the memory stores a computer program that can run on the processor, and when the processor executes the computer program, the method provided by the above-mentioned embodiments is implemented. step.

[0109] see Figure 7 , the electronic device further includes: a bus 703 and a communication interface 704, the processor 702, the communication interface 704 and the memory 701 are connected through the bus 703; the processor 702 is used to execute executable modules stored in the memory 701, such as computer programs.

[0110] Wherein, the memory 701 may include a high-speed random access memory (Random Access Memory, RAM for short), and may also include a non-volatile memory (non-volatile memory), such as at least one disk memory. The communication connection between the system network element and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com