Anti-reflection laser

A laser and light-returning technology, applied in the field of lasers, can solve the problems of laser equipment hazards and failures that cannot be completely solved, and achieve the effects of reducing light absorption power, improving working life, and avoiding burnout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the embodiments and accompanying drawings, but the protection scope of the present invention should not be limited thereby.

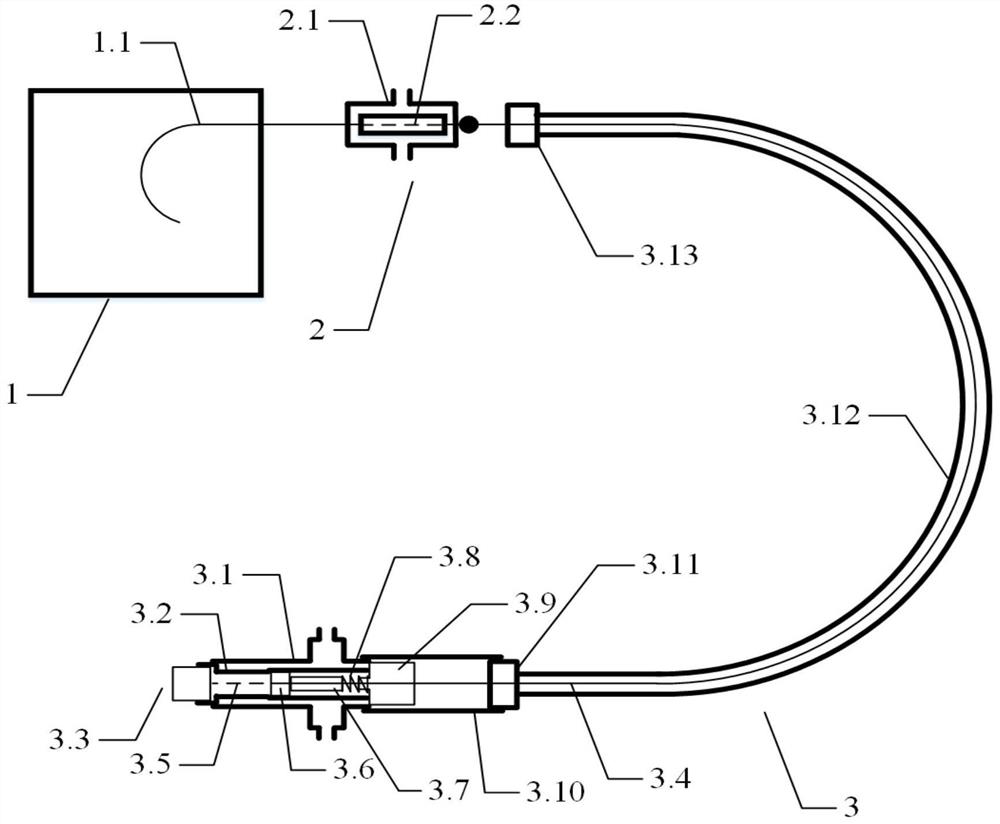

[0024] see first figure 1 , figure 1 It is a structural schematic diagram of the anti-reflection laser of the present invention. It can be seen from the figure that the anti-reflection laser of the present invention includes a laser output module 1, a cladding filter module 2 and an output optical cable 3. The laser output module 1 includes an output The optical fiber 1.1, the cladding filter module 2 includes a water-cooled housing 2.1, the first fiber texturing area 2.2, and the output optical cable 3 includes an output head main body 3.1, an inner core 3.2, a quartz column 3.3, and an output optical cable optical fiber 3.4, the second optical fiber roughening area 3.5, reflective lens 3.6, quartz gasket 3.7, spring 3.8, optical fiber fixing part 3.9, outer sleeve 3.10, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com