Wood polishing device for furniture processing

A technology of polishing device and wood, which is applied in the direction of grinding drive device, metal processing equipment, machine tool for surface polishing, etc., can solve the problems of reduced work efficiency, laborious use of staff, uneven polishing of wood furniture, etc., so as to improve work efficiency , convenient polishing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

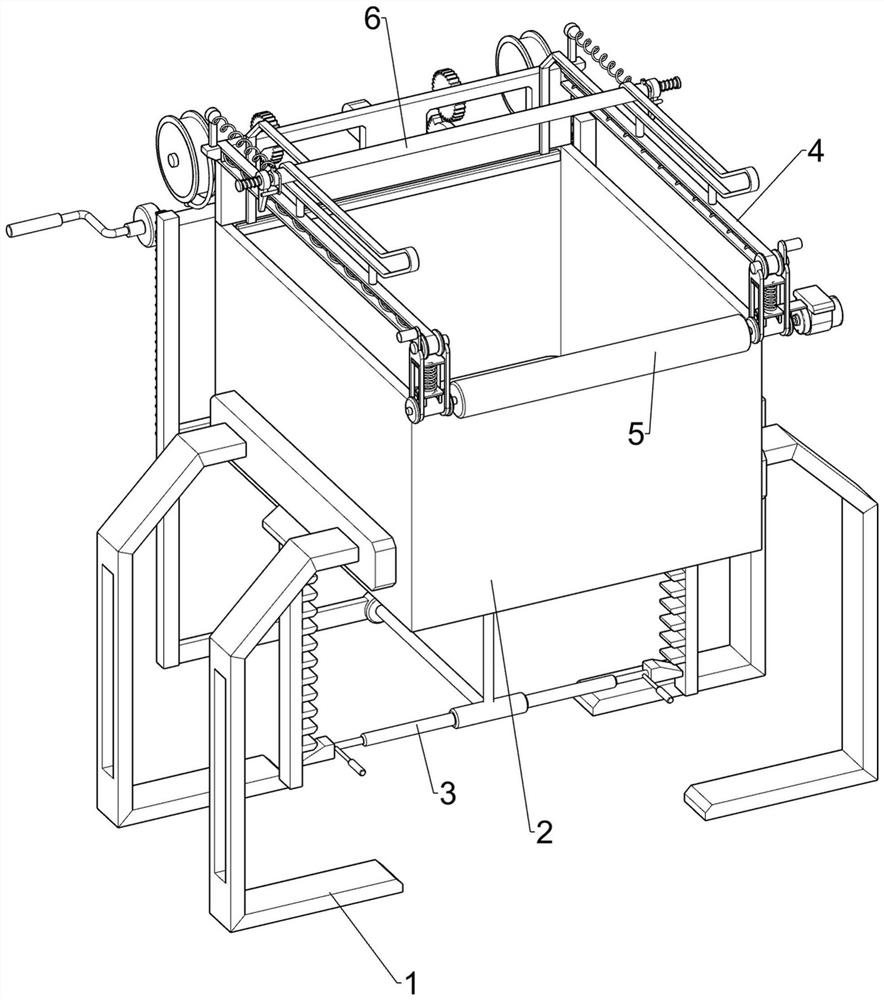

[0028] like figure 1 As shown, a wood polishing device for furniture processing includes a foot base 1, a frame body 2, a lifting mechanism 3, a moving mechanism 4 and a polishing mechanism 5, and a frame body 2 is connected between the four foot bases 1, and the frame body 2 The rear side is provided with a lifting mechanism 3, the frame body 2 is provided with a moving mechanism 4, the moving mechanism 4 cooperates with the lifting mechanism 3, and the moving mechanism 4 is provided with a grinding mechanism 5.

[0029] When the wood needs to be polished, the staff first adds a certain amount of wood into the frame body 2, then controls the lifting mechanism 3 to push the wood upwards, and then drives the grinding mechanism 5 to move through the moving mechanism 4, and the staff starts the grinding mechanism 5 rotate, just can polish the wood below, after polishing is finished, close polishing mechanism 5, push out wood from frame body 2 top and collect and get final product...

Embodiment 2

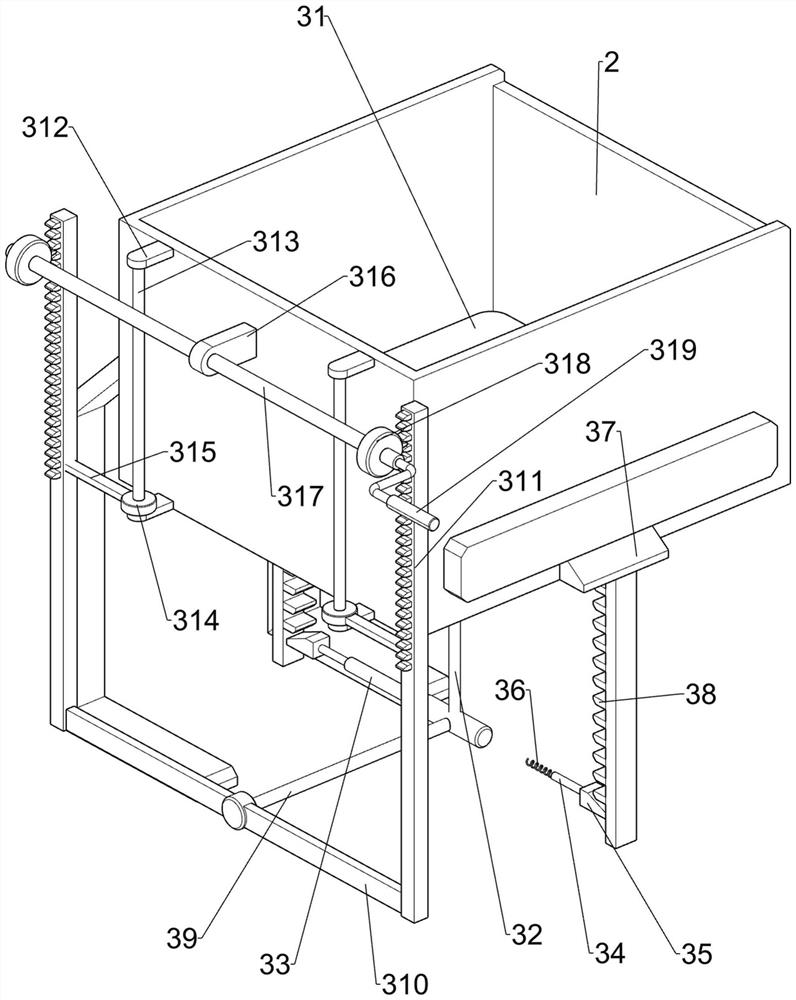

[0031] like figure 2 and image 3As shown, on the basis of Embodiment 1, the lifting mechanism 3 includes a support plate 31, a first slide bar 32, a guide sleeve 33, a second slide bar 34, a first wedge block 35, a first elastic member 36, a first Fixed block 37, the first stop block 38, the first fixed rod 39, the second fixed block 310, the rack 311, the third fixed block 312, the guide rod 313, the first slide block 314, the fourth fixed block 315, the A bearing seat 316, a first rotating shaft 317, a first gear 318 and a first handle 319, a support plate 31 is slidingly provided inside the frame body 2, a first slide bar 32 is provided at the bottom of the support plate 31, and a first slide bar 32 is provided at the bottom of the first slide bar 32 A guide sleeve 33 is provided, and the left and right sides of the guide sleeve 33 are slidably provided with a second slide bar 34, and the ends of the second slide bar 34 are provided with a first wedge block 35, between t...

Embodiment 3

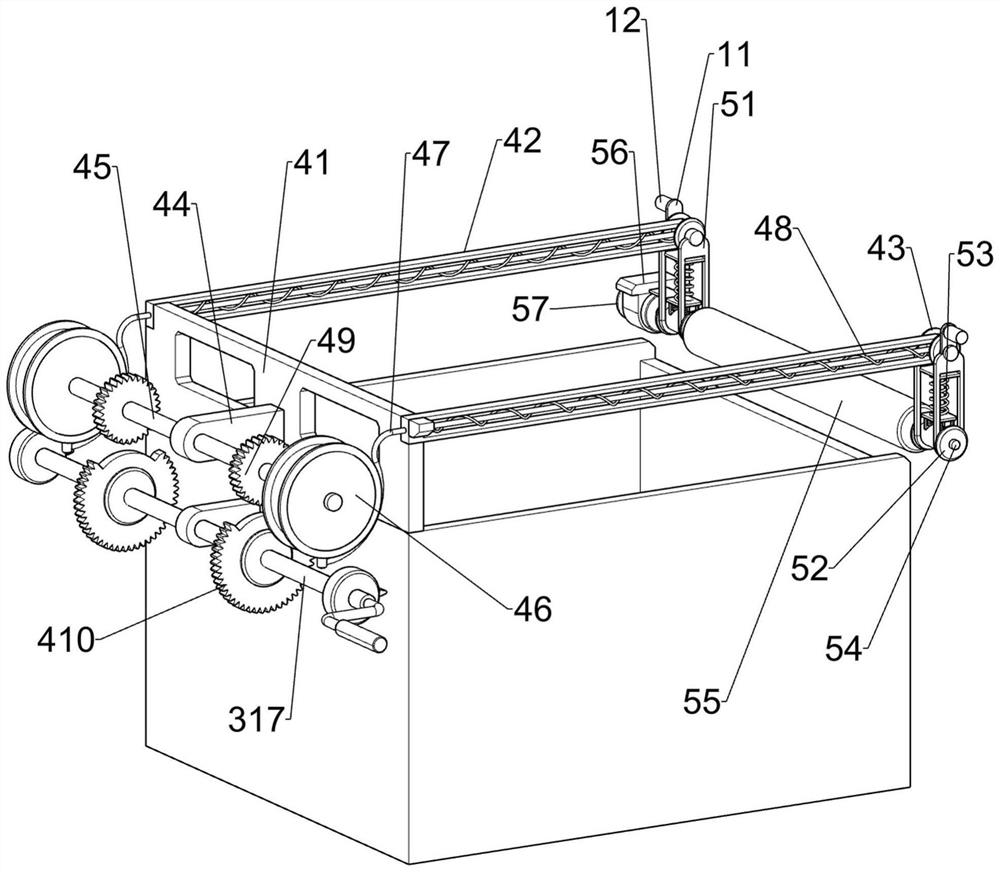

[0037] like Figure 4 and Figure 5 As shown, a wood polishing device for furniture processing also includes a push mechanism 6, the top of the first chute plate 42 is provided with a push mechanism 6, and the push mechanism 6 includes a second fixed rod 61, a third chute plate 62, The third slide bar 63, the seventh fixed block 64, the eighth fixed block 65, the ninth fixed block 66 and the fourth elastic member 67, the left and right sides of the top of the first chute plate 42 are provided with the second fixed rod 61, the The third chute plate 62 is connected between the tops of the two fixed rods 61, the third slide bar 63 is slidably arranged between the third chute plate 62, and the left and right sides of the third slide bar 63 rear portion are all provided with the third slide bar 63. Seven fixed blocks 64, the eighth fixed block 65 is connected between the bottom of the seventh fixed block 64, the ninth fixed block 66 is arranged on the left and right sides of the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com