Austenitic stainless steel pipe anti-falling feeding mechanism

A kind of austenitic stainless steel, anti-fall technology, applied in the direction of grinding machine parts, metal processing equipment, grinding/polishing equipment, etc., can solve the problem that the rolling speed of stainless steel pipes is difficult to control, easy to damage stainless steel pipes, affecting production progress, etc. problem, to achieve the effect of small vibration, good versatility and long service life of the equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

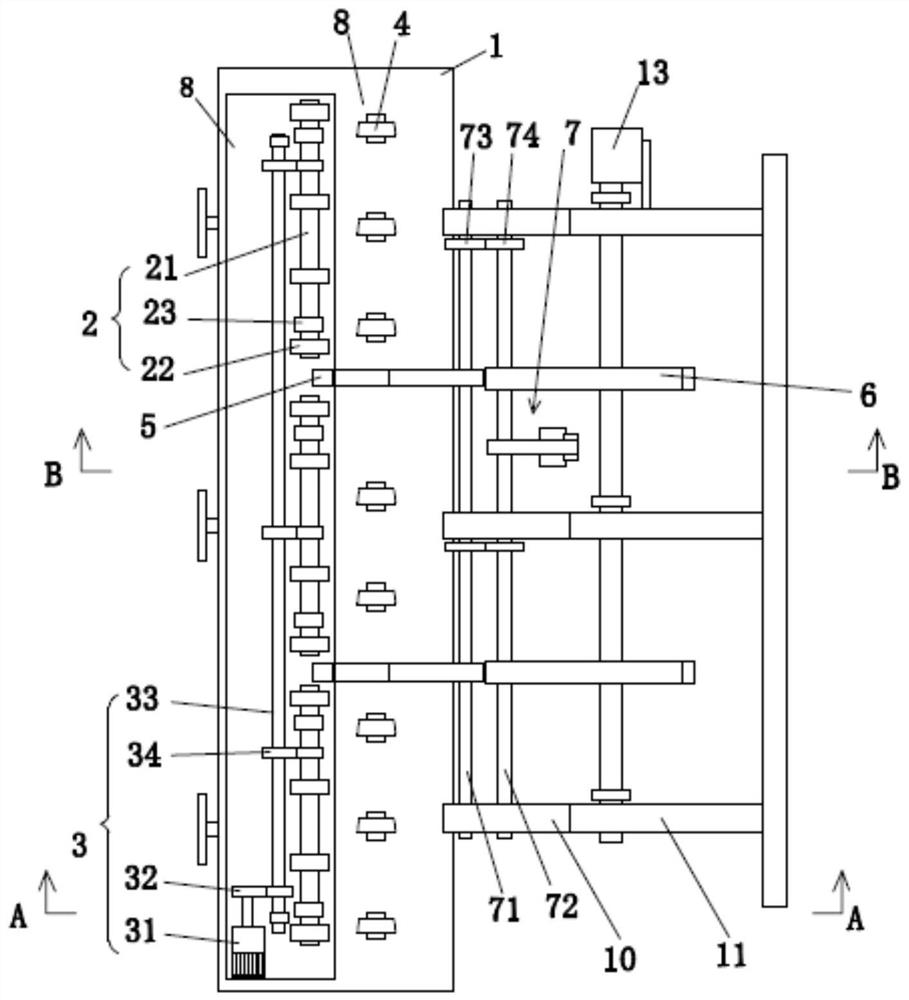

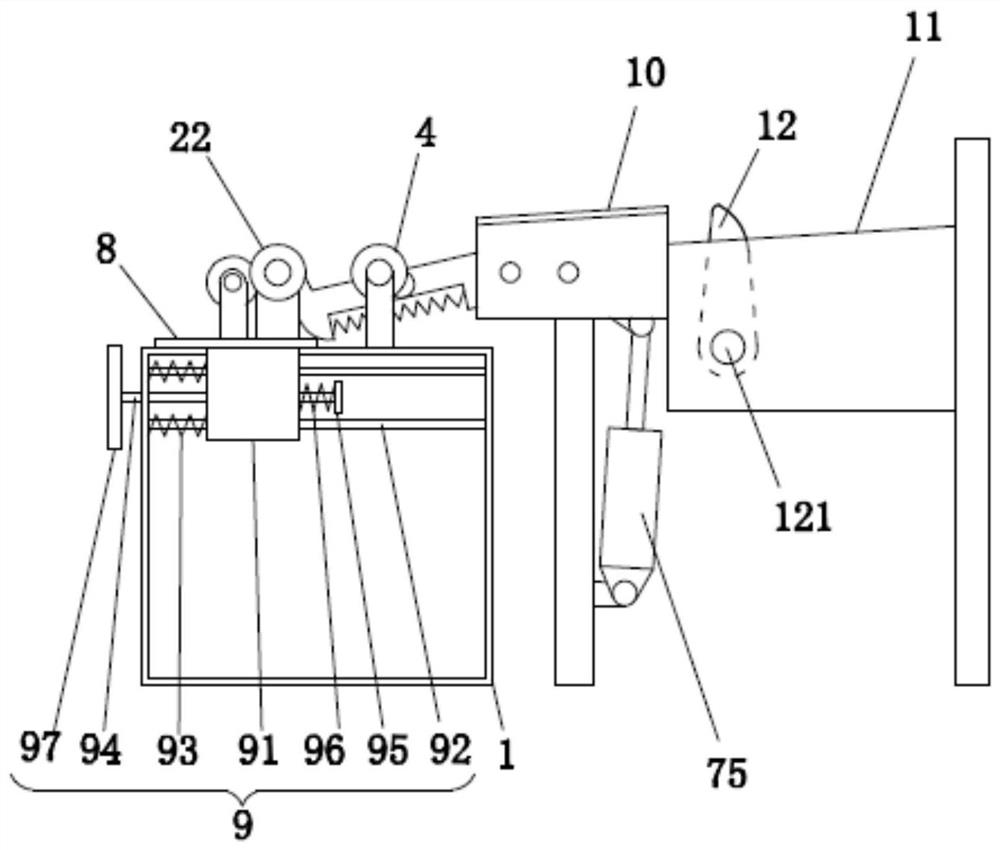

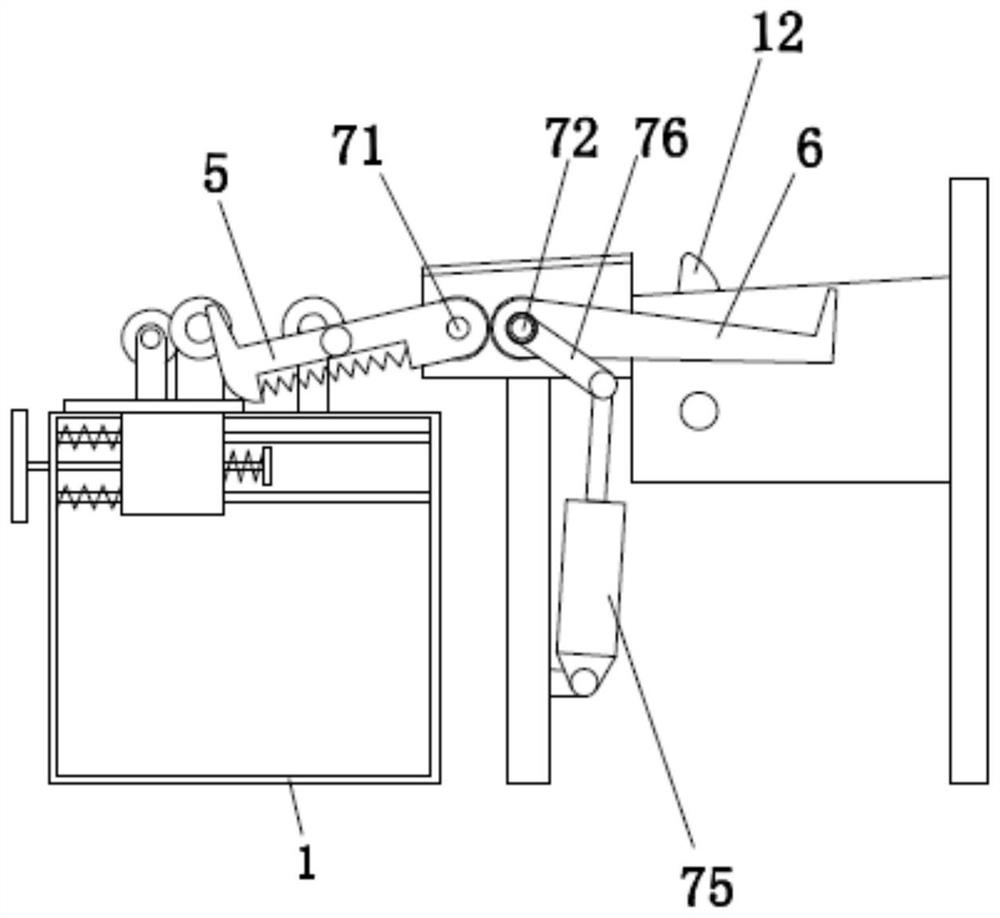

[0025] The specific embodiment of the present invention is as Figure 1 to Figure 4 As shown, an austenitic stainless steel pipe anti-fall feeding mechanism includes a platform 1 on which two rows of conveying support wheels are arranged. One side of the platform 1 is provided with a material storage rack. The storage rack is provided with a material lifting swing arm 6 and a material discharging swing arm 5 which can swing oppositely. Lifting swing arm 6 and discharging swing arm 5 are linked by swing arm drive mechanism 7 . The trajectory of the free end of the discharging swing arm 5 passes between the two rows of conveying support wheels. A transverse buffer device 9 is provided between at least one row of conveying support wheels and the platform 1 .

[0026] The two rows of conveying support wheels include active support wheel sets 2 and non-powered support wheels 4 . Storage rack, unpowered support wheel 4 and active support wheel group 2 are arranged successively. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com