TPU foaming sole manufacturing process and finished product thereof

A technology of forming agglomerates and bubbles, applied in the field of TPU foamed sole manufacturing process and its finished products, can solve problems such as affecting the price of shoes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the above objects, features and features of the present invention more comprehensible, the relevant embodiments of the present invention are described in detail as follows in conjunction with the following figures.

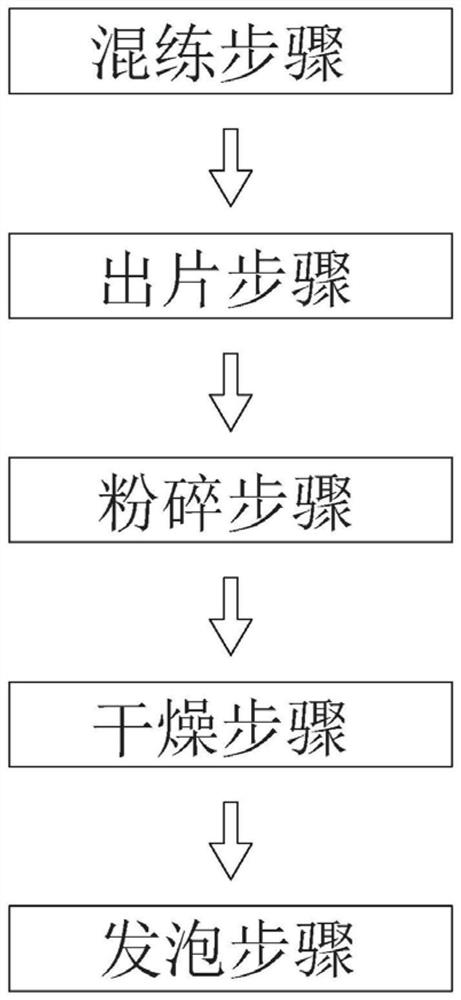

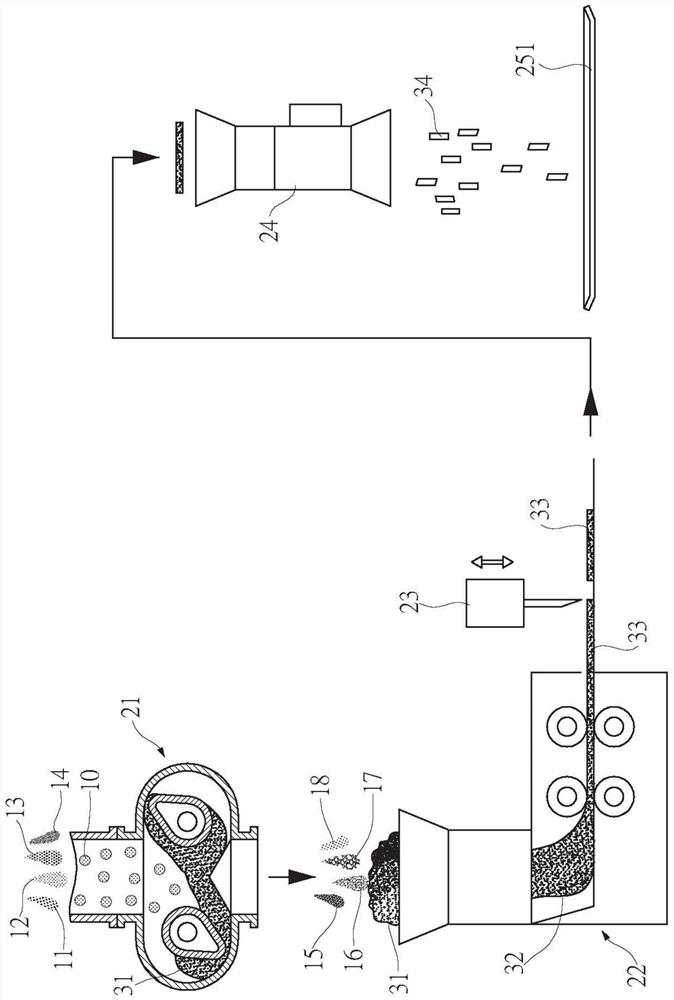

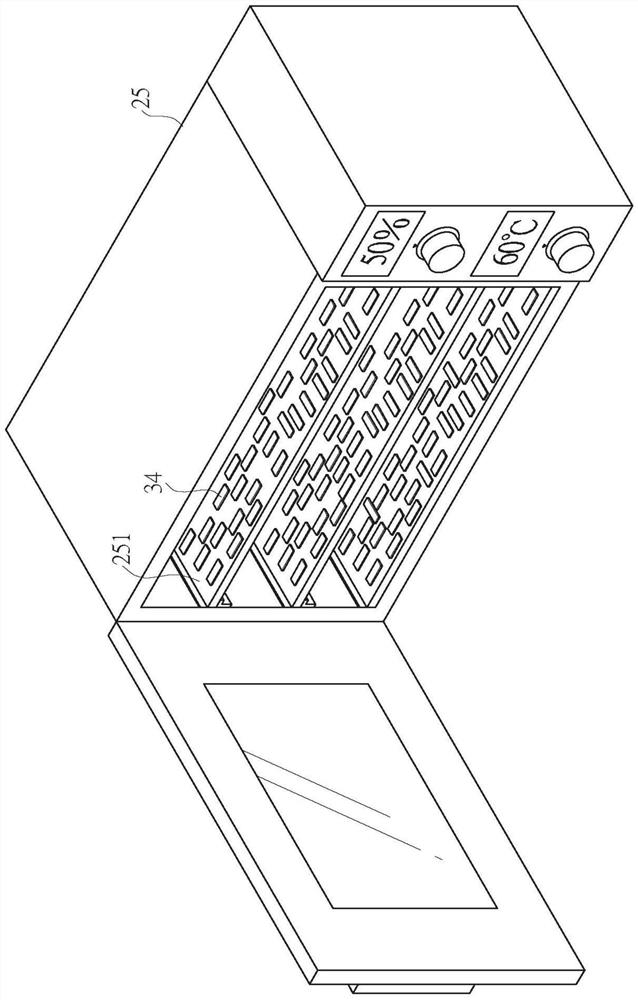

[0034] see figure 1 As shown, the TPU foam sole manufacturing process of the present invention includes a kneading step, a tableting step, a crushing step, a drying step and a foaming step. The following describes the technical characteristics of each step, and please refer to Figure 2 to Figure 6 shown.

[0035] In the kneading step, the thermoplastic polyurethane elastomer 10, the nucleating agent 11, the slip agent 12, the antioxidant 13, and the ultraviolet absorber 14 are put into the kneading machine 21, and the agglomerated rubber compound 31 is obtained through heating and kneading;

[0036] In the tableting step, the aforementioned agglomerated rubber material 31 is put into the tablet press machine 22, and foaming agent 15, cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com