Roller type textile printing device

A textile and printing technology, applied in the field of textile printing, can solve problems such as pollution and poor quality of printed products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

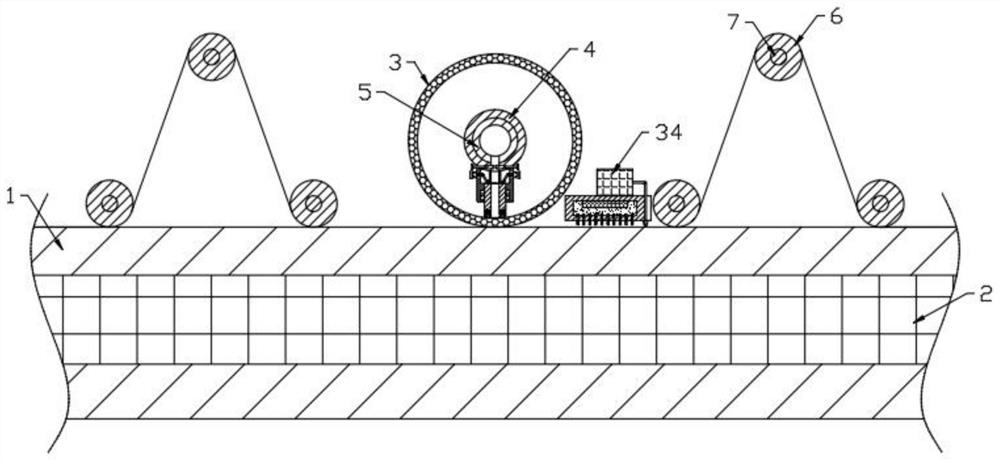

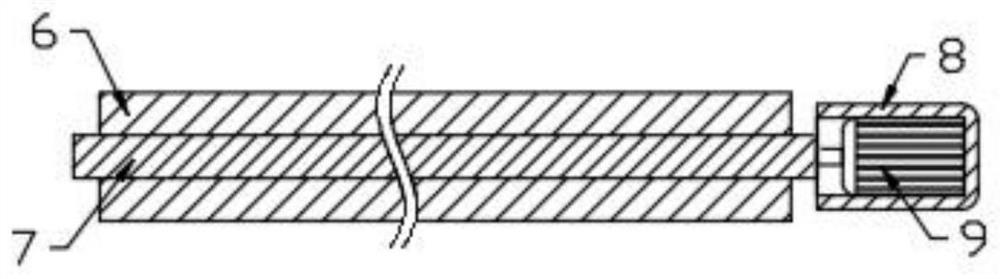

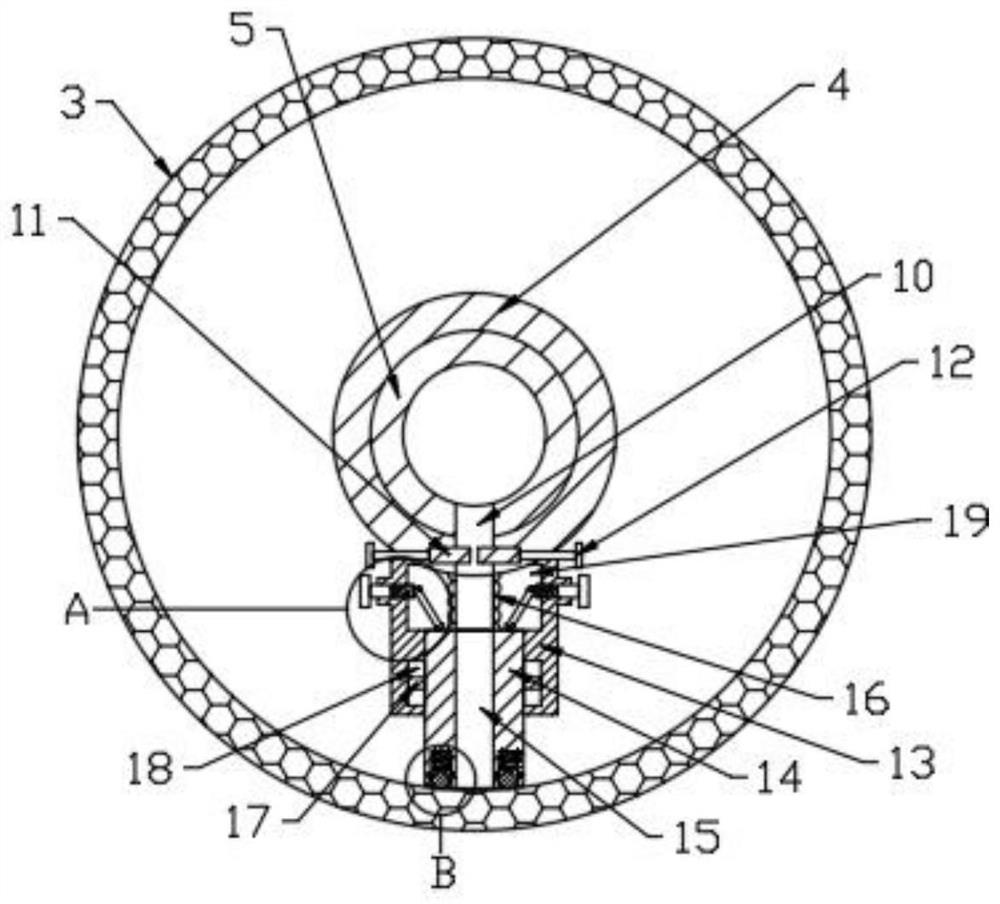

[0030] see Figure 1-10 , a roll-type textile printing device, comprising a workbench 1 and a magnetic table 2 arranged in the workbench 1, a frame body is arranged on the workbench 1, a number of dyeing rollers 3 are arranged on the workbench 1, and the dyeing rollers 3 A knife rest 4 and an infusion tube 5 are arranged inside, and a number of transportation components for transporting textiles are interlaced between several dyeing rollers 3. Through holes 10 are provided on the lower sides of the knife rest 4 and the infusion tube 5, and on the knife rest 4, there are There is a control assembly for controlling the content of color paste output from the through hole 10, a guide seat 13 is fixedly connected to the lower end of the knife holder 4, a scraper 14 is slidingly connected to the guide seat, an infusion channel 15 is provided in the scraper 14, and a cavity is provided in the guide seat 13 19. The cavity 19 is provided with a hose 16 communicating with the through ho...

Embodiment 2

[0049] Further improvements are made on the basis of Example 1, and the improvements are as follows: the pretreatment assembly includes a heating plate 37, a slurry suction cylinder 38, a second slurry suction head 39, a through cavity 40, a communication pipe 43 and a second negative pressure pump 44. A number of heating plates 37 are arranged on both sides of the dyeing roller 3 on the workbench 1, and a number of slurry suction cylinders 38 are symmetrically arranged on both sides of the textile between the transport components. The upper part is fixedly connected with some second slurry suction heads 39, and the second slurry suction head 39 communicates with the through cavity 40 in the slurry suction tube 38. One end of the through cavity 40 is provided with a connecting pipe 43 that is rotatably connected with the slurry suction tube 38, and the connecting tube 43 communicates with the output end of the second negative pressure pump 44, the second negative pressure pump ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com