Separator for contaminated garment and quilt pneumatic conveying system

A technology of pneumatic conveying system and separator, which is applied in the field of pneumatic conveying system for dirty clothes and bedding, and can solve the problems of inability to transmit in multiple channels, unable to control the direction of transmission, and the separator can only transmit in one direction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

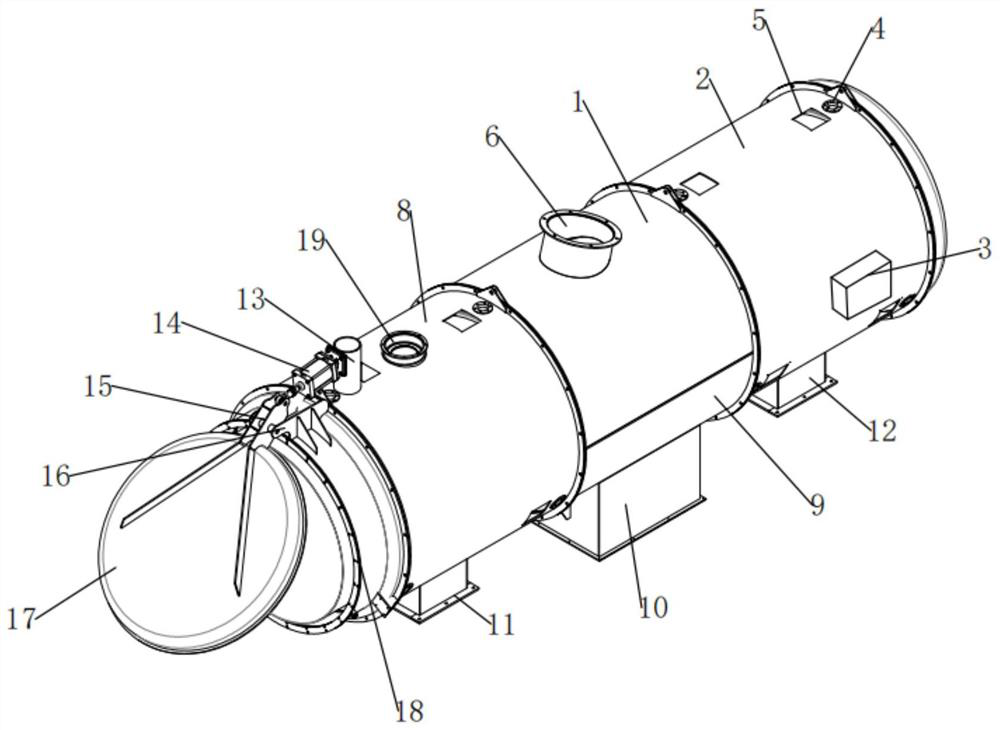

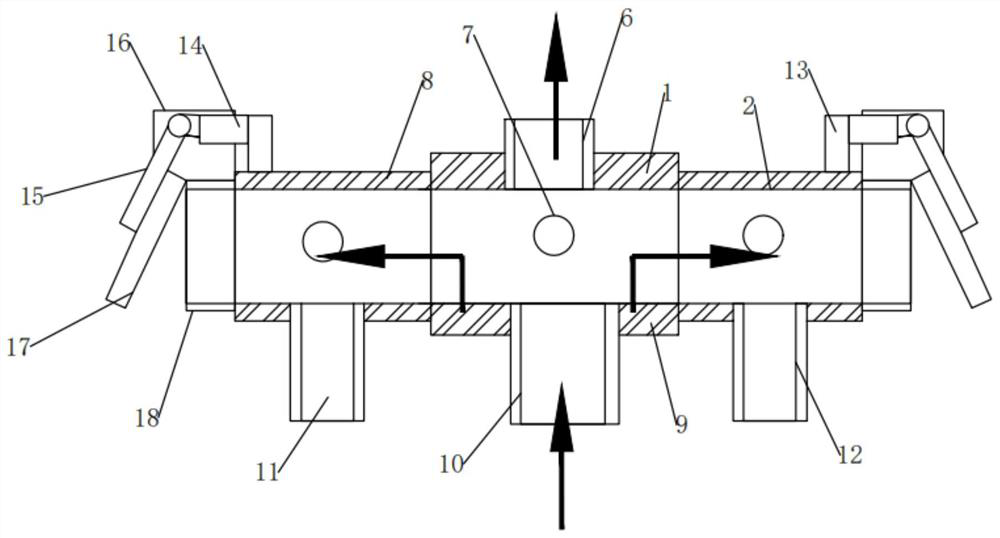

[0028] see Figure 1-2 , a separator for a pneumatic conveying system for dirty clothes, comprising an upper clamp 1, the upper end of the upper clamp 1 is fixedly connected with a lower clamp 9, and the right ends of the upper clamp 1 and the lower clamp 9 are fixedly connected with a second clamp A transmission pipe 2, the left ends of the upper clamp 1 and the lower clamp 9 are fixedly connected with the second transmission pipe 8, and the opposite ends of the first transmission pipe 2 and the second transmission pipe 8 are fixedly connected with a sealing valve frame 18, and the upper The lower end of the clamp 1 is fixedly connected with a feed hole 10, the upper end of the upper clamp 1 and the first transmission pipe 2 are fixedly connected with a support column 13, and the opposite ends of the two support columns 13 are fixedly connected with a telescopic cylinder 14. The upper ends of each sealed valve frame 18 are fixedly connected with a support frame 16, and the op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com