Uncoiling mechanism for multi-layer metal composite rolling

A composite rolling, multi-layer metal technology, used in metal processing equipment, machine tools suitable for grinding workpiece edges, manufacturing tools, etc. Combining problems such as inability to accurately align to achieve the effect of ensuring production quality and reducing the possibility of offset

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

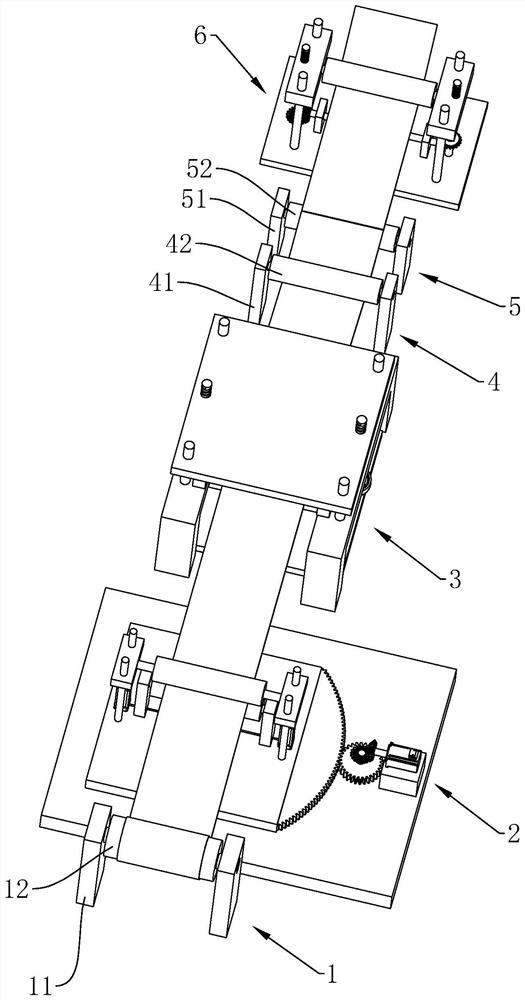

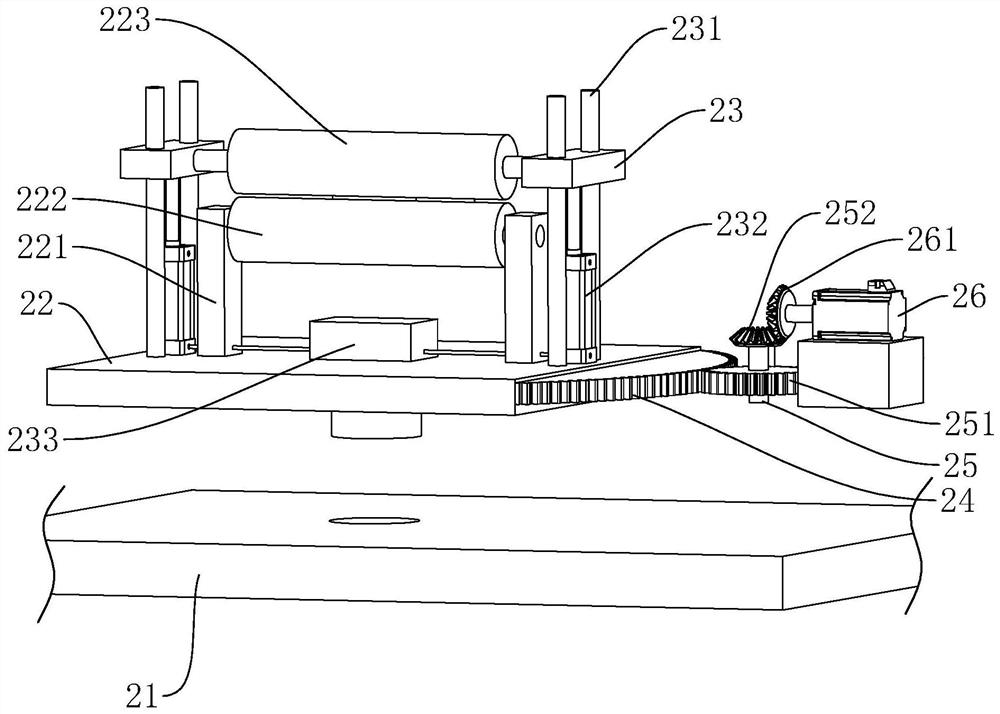

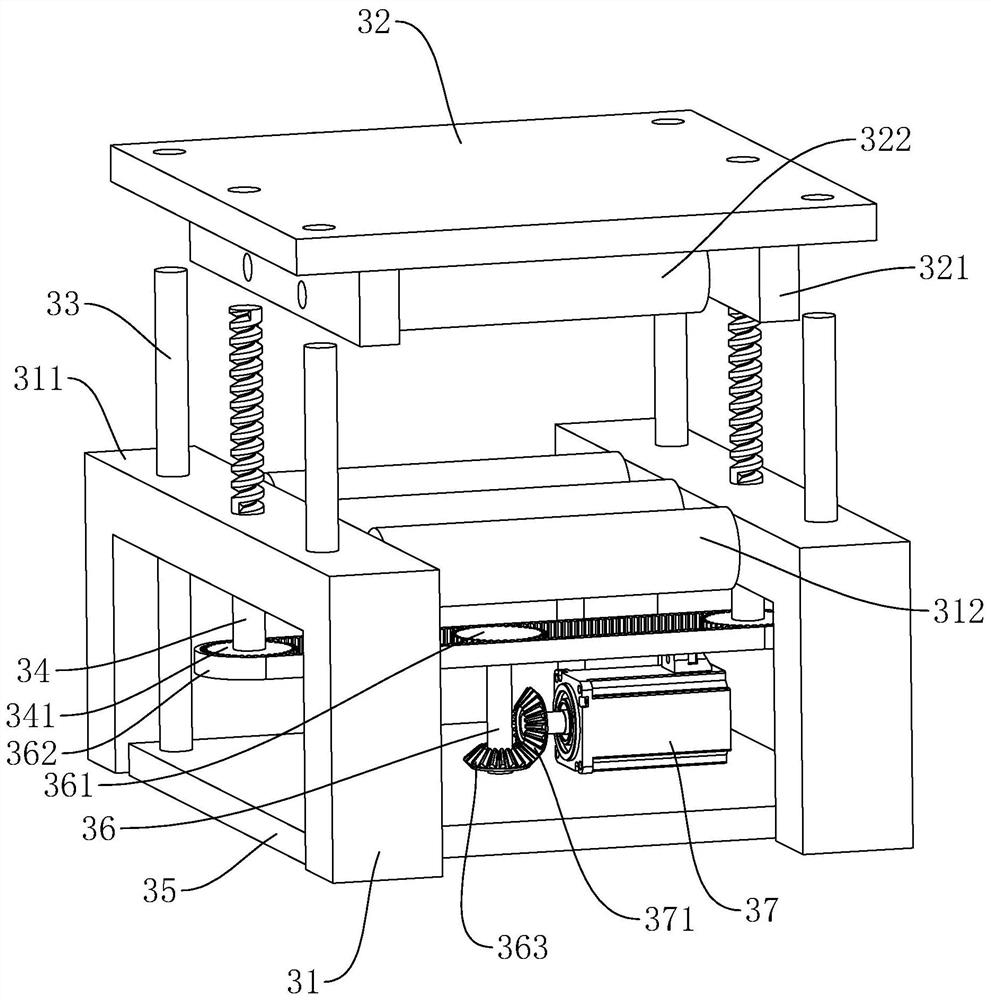

[0035] The following is attached Figure 1-4 The application is described in further detail.

[0036] The embodiment of the present application discloses an uncoiling mechanism for multi-layer metal composite rolling. refer to figure 1 , the upper uncoiling mechanism includes an unwinding machine 1, a deviation correcting machine 2, a grinding machine 3, a first conveyor 4, a second conveyor 5 and a guiding machine 6 arranged in sequence. The unwinding machine 1 unwinds the metal sheet, and the metal sheet When the direction of travel of the sheet is deflected, use the deviation correcting machine 2 to correct the deviation, use the grinder 3 to grind the metal sheet, and the metal sheet moves to the guide machine 6 through the first conveyor 4 and the second conveyor 5, and uses the guide Machine 6 can guide the metal sheet accurately into the compound rolling mill.

[0037] refer to figure 1 , The unwinding machine 1 includes two supporting columns 11, and an unwinding rol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com