Door body structure used for vacuum chamber

A vacuum chamber and door body technology, applied in vacuum evaporation plating, ion implantation plating, gaseous chemical plating, etc., can solve complex manual installation and disassembly, cumbersome opening and sealing process of vacuum chamber, time-consuming and laborious, etc. Problems, to achieve the effect of convenient and fast disassembly, improve connection stability, and increase contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

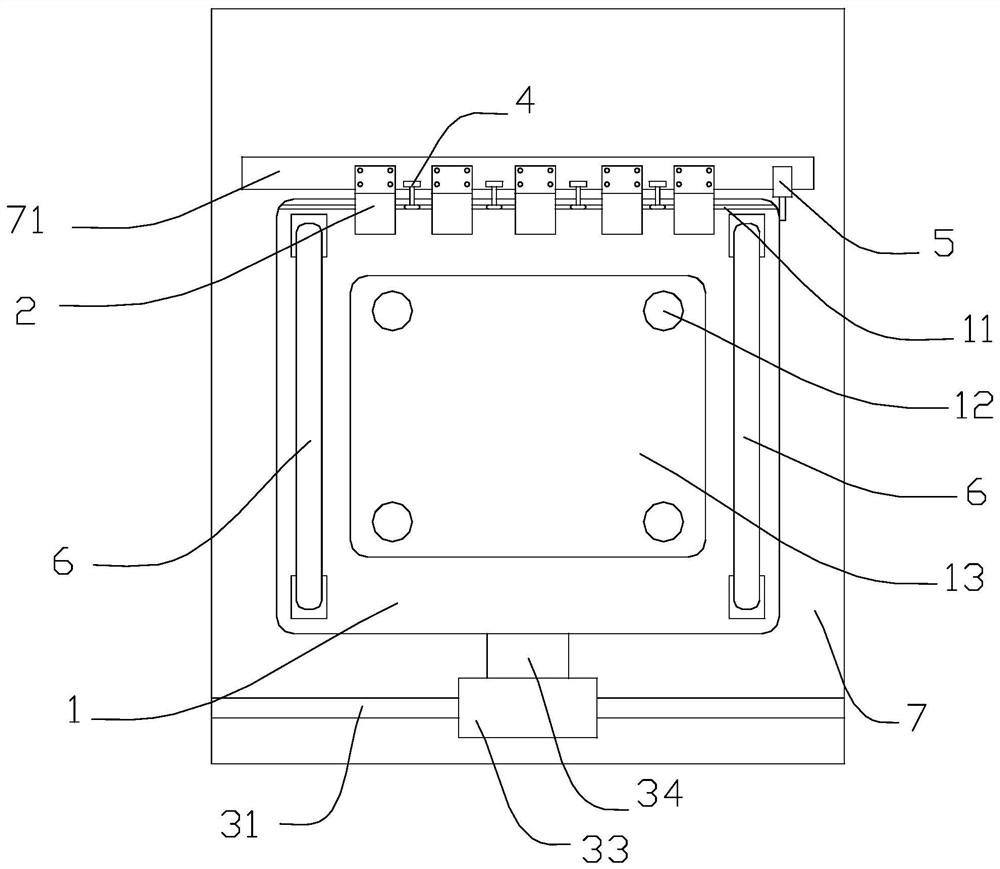

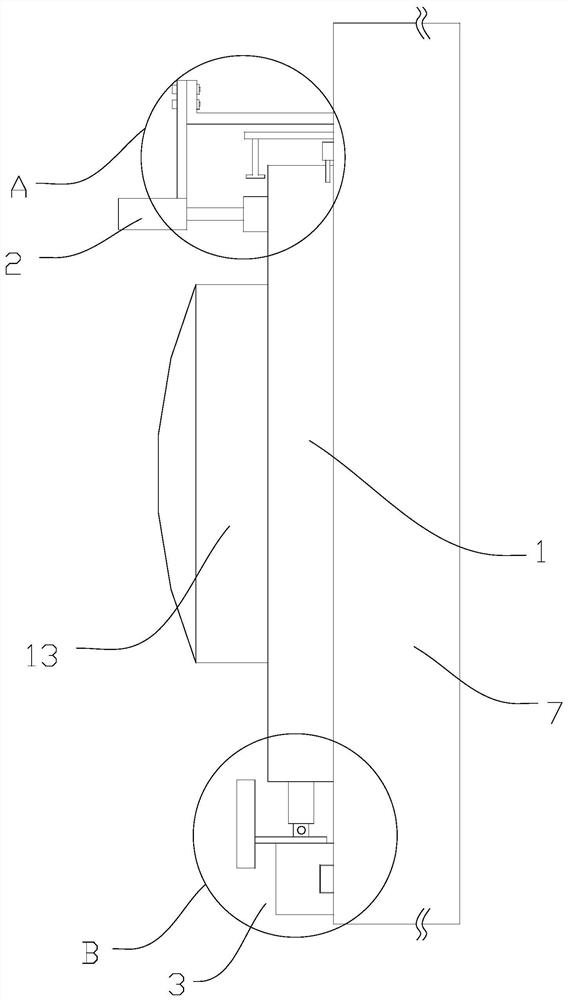

[0032] Such as Figure 1-3 As shown, the door body structure for the vacuum chamber includes a body 1 that can be movably arranged at the opening of the vacuum chamber 7, and the body 1 is used to close the opening of the vacuum chamber 7, so that the vacuum chamber 7 In a sealed state, it can be vacuumized and coated.

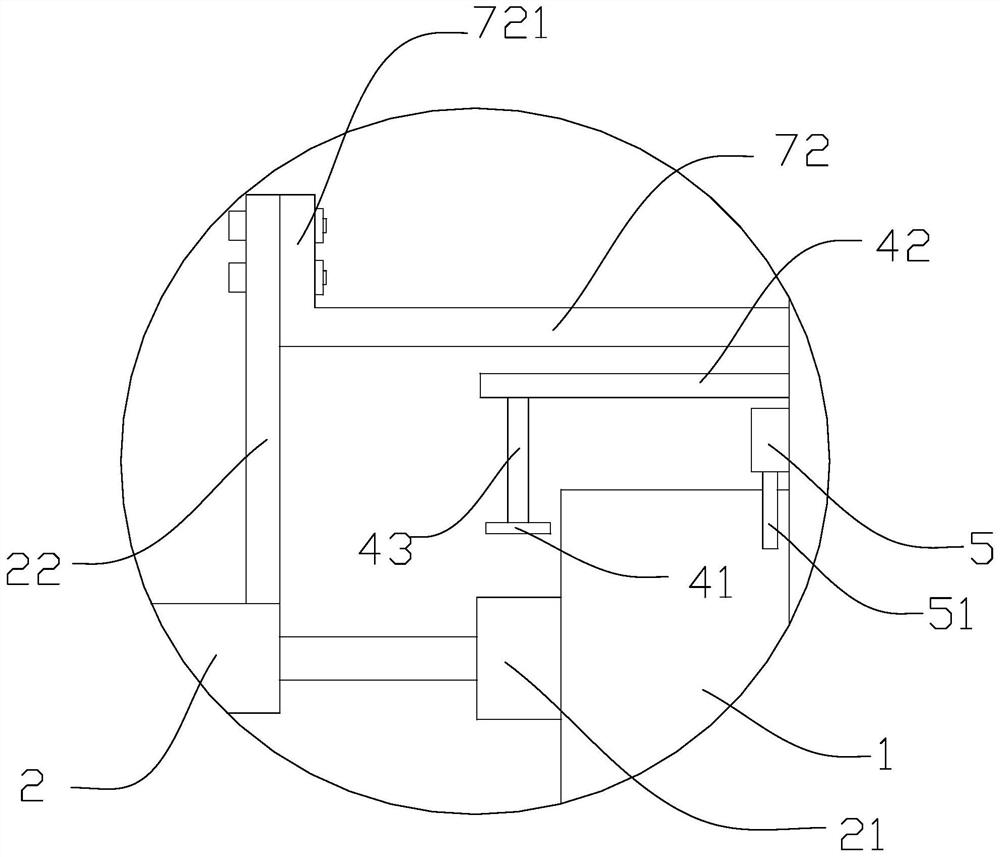

[0033] Wherein, a mounting part 71 is provided on the outer wall of the vacuum chamber 7 above the opening, and a plurality of fixed cylinders 2 are provided on the mounting part 71 .

[0034] When the body 1 coincides with the opening, the fixed cylinder 2 is in contact with the surface of the body 1 to press the body 1 against the outer wall of the vacuum chamber 7 .

[0035] When the body is misaligned with the opening, the fixed cylinder 2 stops working, and the surface of the body 1 obliquely touches the fixed cylinder 2 .

[0036] Wherein, the piston rod of the fixed cylinder 2 is provided with a pressure block 21 for conflicting with the body 1 .

[...

specific Embodiment 2

[0054] Such as Figure 1-4 As shown, the mounting portion 71 is provided with a plurality of limit rods 4, the limit rod 4 is provided with a sliding wheel 41, and the body 1 is provided with a guide that matches the sliding wheel 41. Groove 11.

[0055] Specifically, when the body 1 and the vacuum chamber 7 are disengaged, the body 1 is inclined under the action of the protrusion 13, and the sliding wheel 41 is inserted into the guide groove 11 to play a position-limiting role. , while improving the accuracy and stability of the displacement of the main body 1 .

[0056] Further, the limiting rod 4 is composed of a fixing part 42 and a limiting part 43, which are arranged in the shape of a "7", the fixing part 42 is connected with the installation part 71, and the limiting part 43 is sleeved with the The limiting wheel 41 is described.

[0057] Wherein, the guide device 3 includes a guide rail 31, a slider 32, a baffle plate 33 and a connecting block 34, the guide rail 31 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com