A double helix pipe, grouting pile forming equipment and construction method for strengthening soft soil

A soft soil, double-helix technology, applied in the field of grouting pile equipment and double-helix pipes, can solve the problems of high water content, weak soil strength and low bearing capacity, and achieve reduced water content, increased area, and Strong pulling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] In order to further understand the present invention, preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

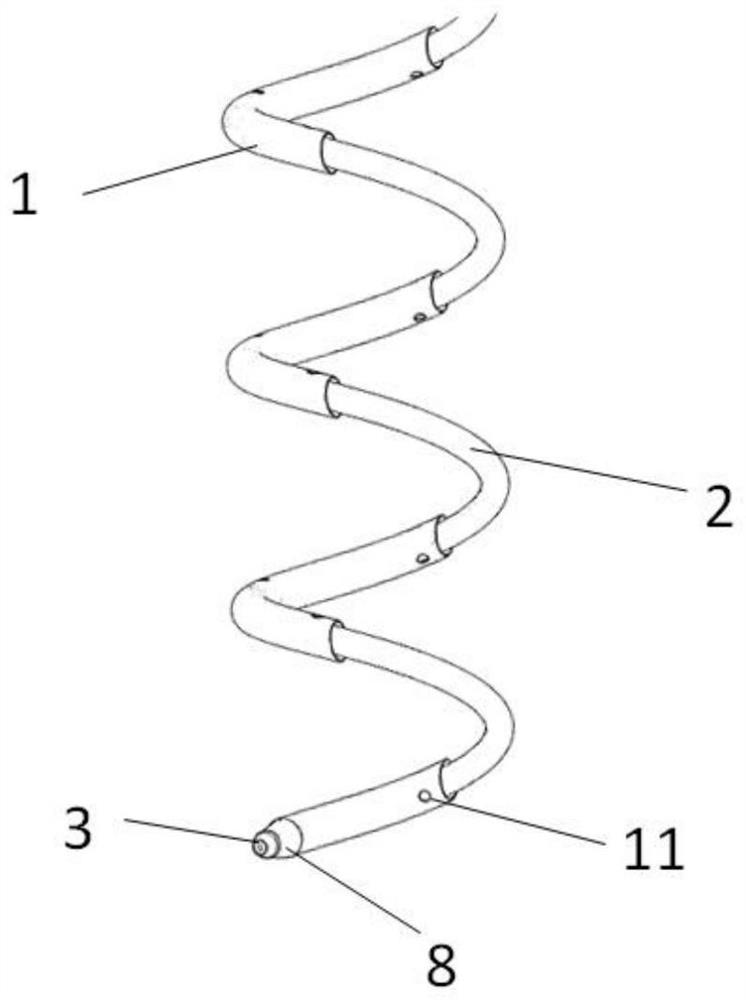

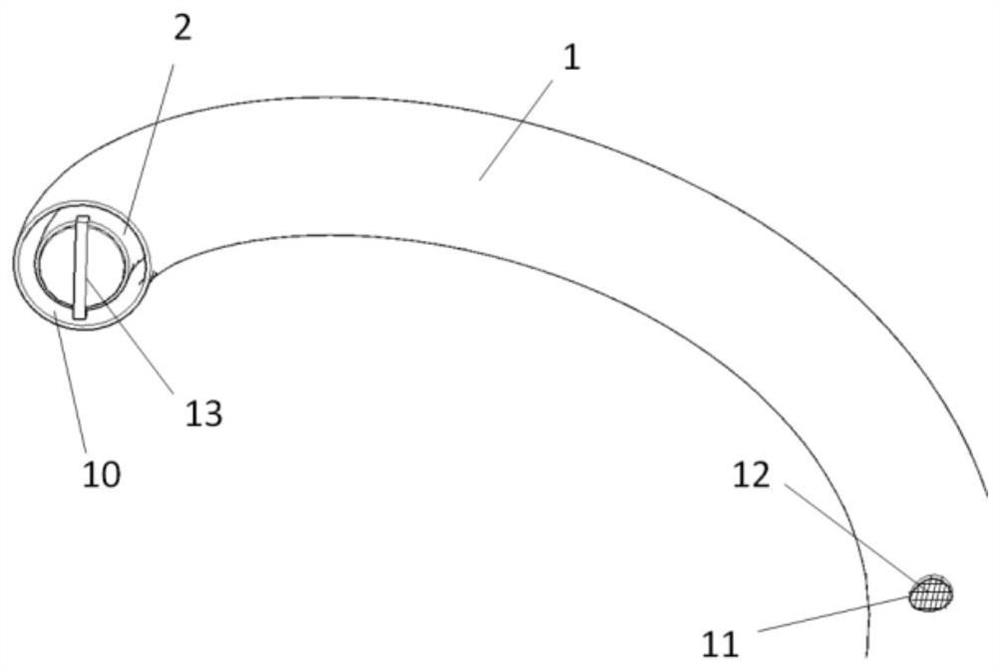

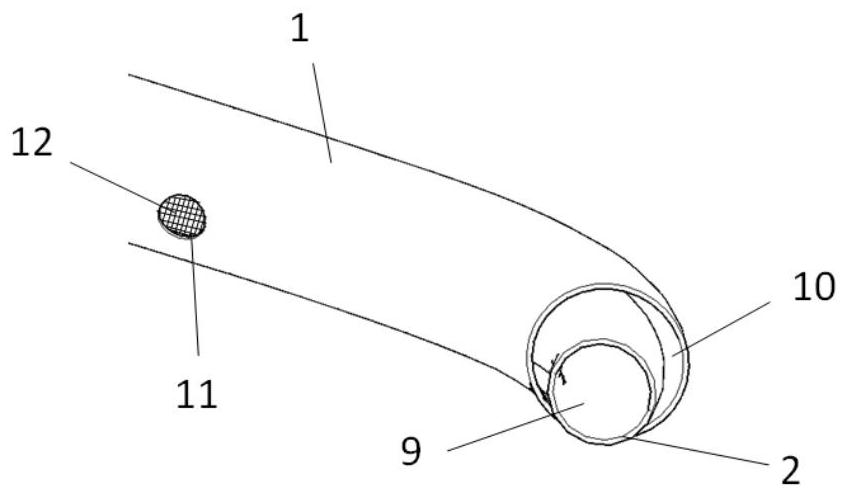

[0048] Refer to attached Figure 1-4 , a double helical pipe for strengthening weak soil, comprising an outer helical pipe 1 and an inner helical pipe 2, the outer helical pipe 1 and the inner helical pipe 2 are nested and fixed together, and the inner and outer helical pipes are nested and welded together The overall length of the helical pipe structure is compatible with the thickness of the soft seabed soil layer and construction requirements, and the length of the inner helical pipe along the helical direction is slightly longer than the length of the outer helical pipe along the helical direction. The outer helical tube 1 and the top of the inner helical tube 2 are sealed and connected, the inner space of the inner helical tube 2 forms a grouting cavity, and the space between the oute...

Embodiment 2

[0059] The basic technical solution is the same as that of the preferred embodiment 1, except that the inner diameter ratio of the inner and outer helical tubes is 1:1.7. In order to ensure the integrity of the equipment, the double helical tubes and the cabin box are integrally welded through the connecting part.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com