Tracking-free solar concentrating system

A technology of solar concentrating and concentrating mirrors, which is applied in the field of solar concentrating, can solve problems such as solar thermal power generation, and achieve the effects of expanding the scope of application, increasing energy flux density and concentrating ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

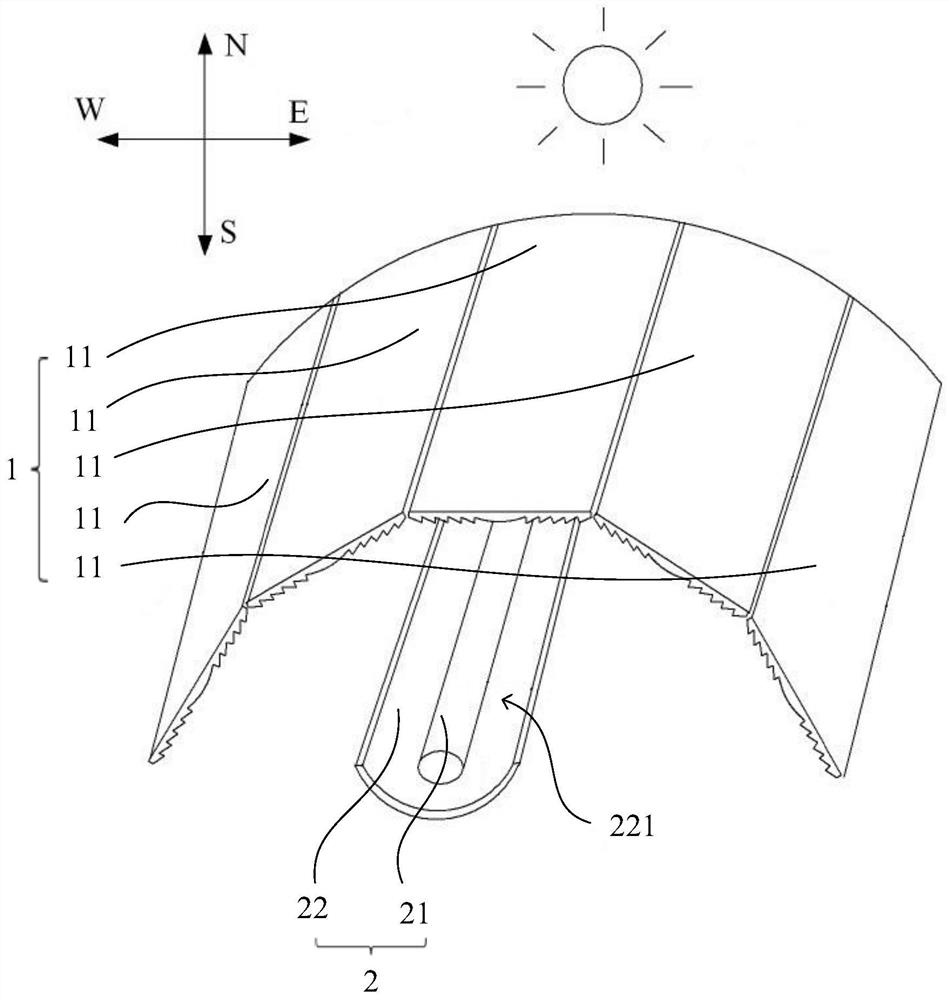

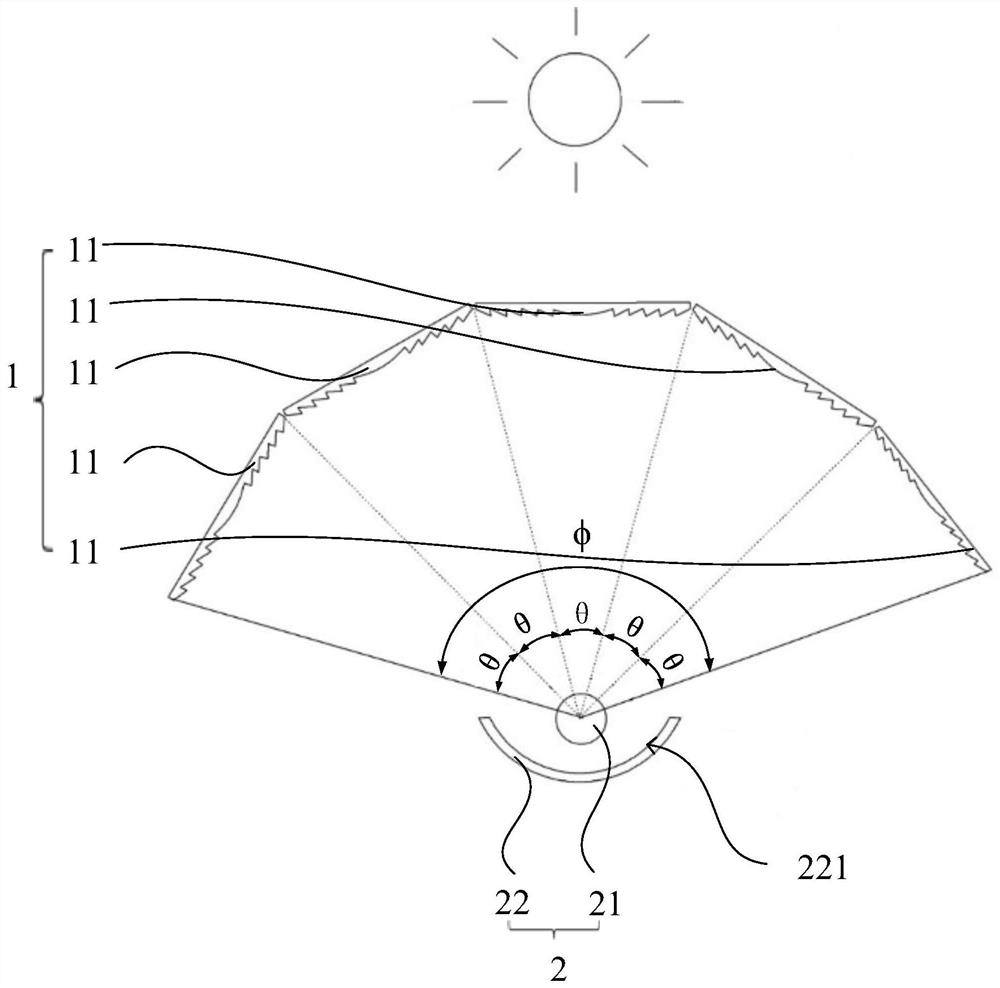

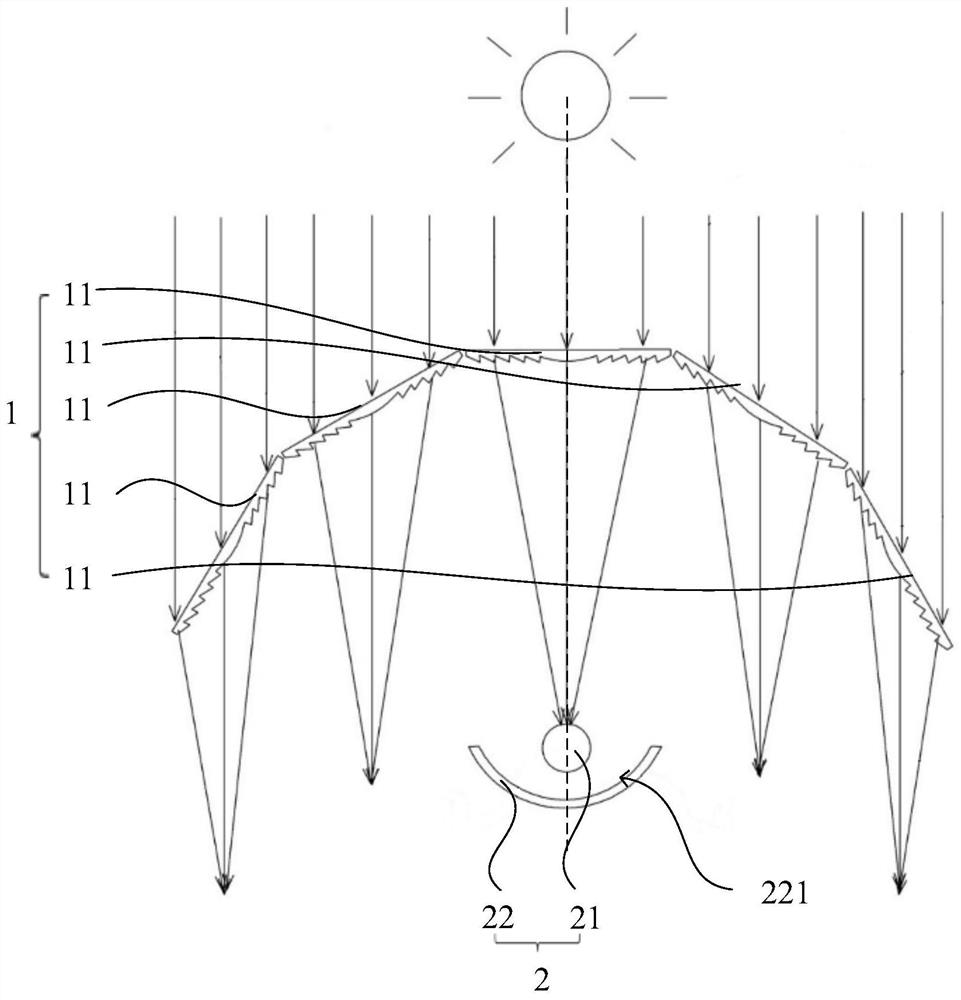

[0044] This embodiment provides a tracking-free solar concentrating system, which is used to collect heat in light in real time without tracking changes in the sun's incident angle. Wherein, the change of the sun incident angle includes the change of the sun altitude angle and the change of the sun azimuth angle. Such as Figure 1-2 As shown, the tracking-free solar concentrating system includes a primary concentrating unit 1 and a heat concentrating unit 2, the primary concentrating unit 1 surrounds the outside of the heat concentrating unit 2, and the light passes through the primary concentrating unit 1 and then focuses to the heat concentrating unit 2 superior.

[0045] The primary concentrating unit 1 includes several transmissive converging lenses 11. In this embodiment, the number of transmissive concentrating lenses 11 of the primary concentrating unit 1 is five, and the five transmissive converging lenses 11 are sequentially spliced to form a primary concentrating ...

Embodiment 2

[0065] The structure of the tracking-free solar concentrating system in Embodiment 2 is basically the same as that in Embodiment 1, except that the arrangement directions of the transmissive concentrators 11 and the heat-gathering parts 2 are different, and the number of transmissive concentrators 11 is different.

[0066] Such as Figure 6 As shown, the transmission condenser 11 in the present embodiment is arranged along the east-west direction, that is, the focal line of the transmission condenser 11 is parallel to the east-west direction, and the heat-absorbing tube 21 and the secondary condenser 22 are also arranged along the east-west direction, and the axes of the heat-absorbing tube 21 are parallel At the focal line of the transmission condenser 11. In this embodiment, the number of transmission condensers 11 is three, and the three transmission condensers 11 are sequentially spliced along the north-south direction to form an arc-shaped primary condenser unit 1 . Wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com