A kind of multilayer graphene fiber paper and preparation method thereof

A multi-layer graphene and fiber paper technology, applied in special paper, papermaking, layered products, etc., can solve the problems of reduced use efficiency, lack of super-hydrophobic surface wettability, limited practical application, etc. Application, the effect of increasing three-dimensional storage space, increasing toughness and foldability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

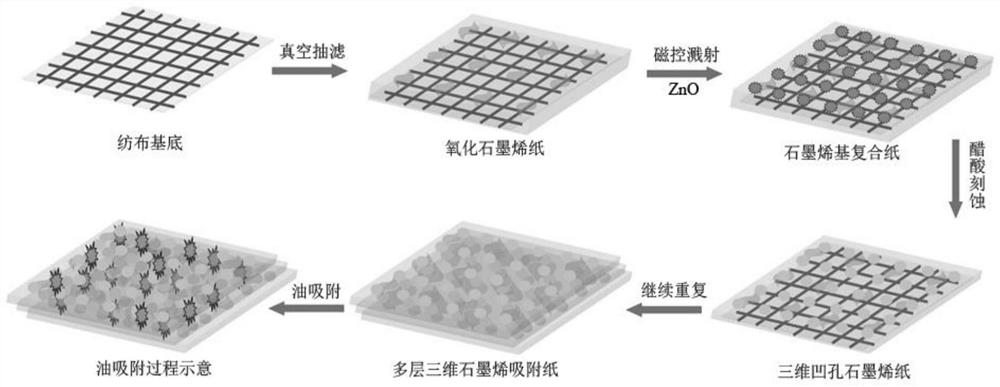

[0033] Below in conjunction with accompanying drawing, the present invention is described in further detail, the present invention discloses a kind of multi-layer graphene fiber paper and preparation method thereof; figure 1 , the preparation method specifically comprises the following steps:

[0034] Step 1, the graphene oxide stock solution is prepared from natural graphite powder by the improved Hummers method, the graphene oxide stock solution is vacuum-filtered to obtain graphene oxide, and the graphene oxide after vacuum-suction filtration is ultrasonically dispersed in deionized water to obtain oxidized Preliminary ultrasonic dispersion of graphene, the initial ultrasonic dispersion of graphene oxide with hydrochloric acid solution to remove metal ions, hydrochloric acid solution to remove metal ions is better, and then repeatedly wash graphene oxide with deionized water to remove the surface of graphene oxide acid solution until the pH value of the preliminary ultrason...

Embodiment 1

[0052] Step 1, the graphene oxide stock solution is prepared by the improved Hummers method from natural graphite powder, which is a bright yellow mixture, and the graphene oxide bright yellow mixture is suction-filtered, and cleaned with 1000mL of 10wt.% hydrochloric acid solution to remove metal ions, and then deionized water Wash and remove the acid solution repeatedly until the pH value of the preliminary ultrasonic dispersion is neutral; the treated graphene oxide preliminary ultrasonic dispersion is suction-filtered, and the suction-filtered product is dried under vacuum at 60°C to obtain the pretreated Graphene oxide powder. Put 50 mg of pretreated graphene oxide powder into 100 mL of deionized water for ultrasonic dispersion for 1 h, and then centrifuge the obtained graphene oxide solution at a speed of 4800 r / min to obtain a uniform and stable yellow-brown graphene oxide clarified solution, It is a precursor solution, wherein the concentration of graphene oxide is 0.5...

Embodiment 2

[0060] In step 1, put 10 mg of the pretreated graphene oxide powder into 100 mL of deionized water for ultrasonic dispersion for 1 h, and obtain a precursor solution with a graphene oxide concentration of 0.1 mg / mL after centrifugation;

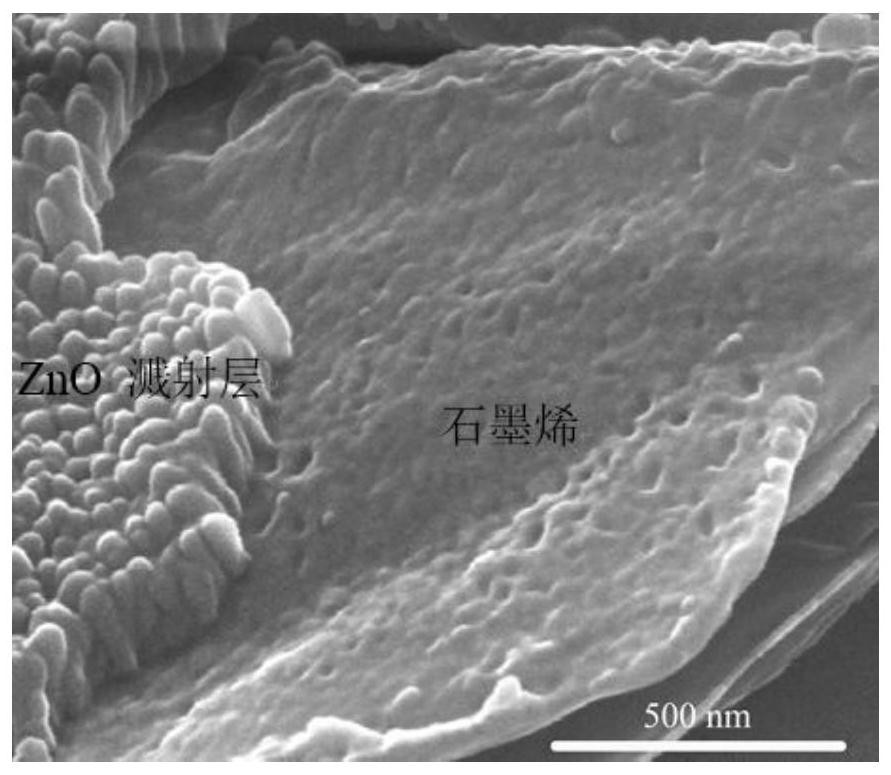

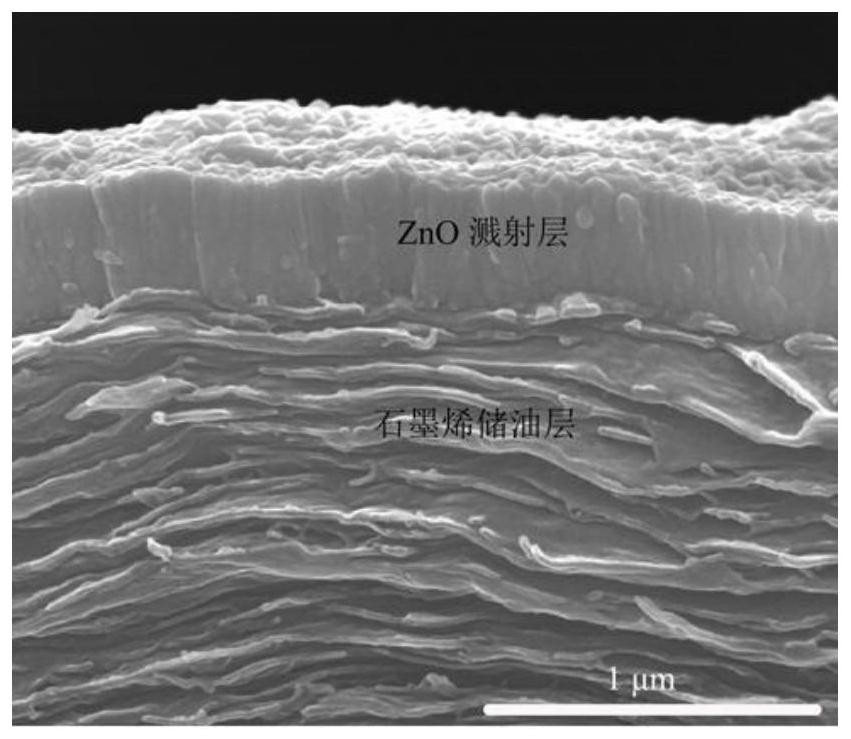

[0061] In step 3, the sputtering deposition temperature is 22°C, the sputtering power is 100W, and the sputtering is 1h, and the thickness of the formed ZnO film is 350nm; a layer of graphene film is formed;

[0062] In step 5, repeat step 2, step 3 and step 4 altogether 8 times, finally make multi-layer graphene fiber paper.

[0063] All the other unwritten steps and parameters are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com