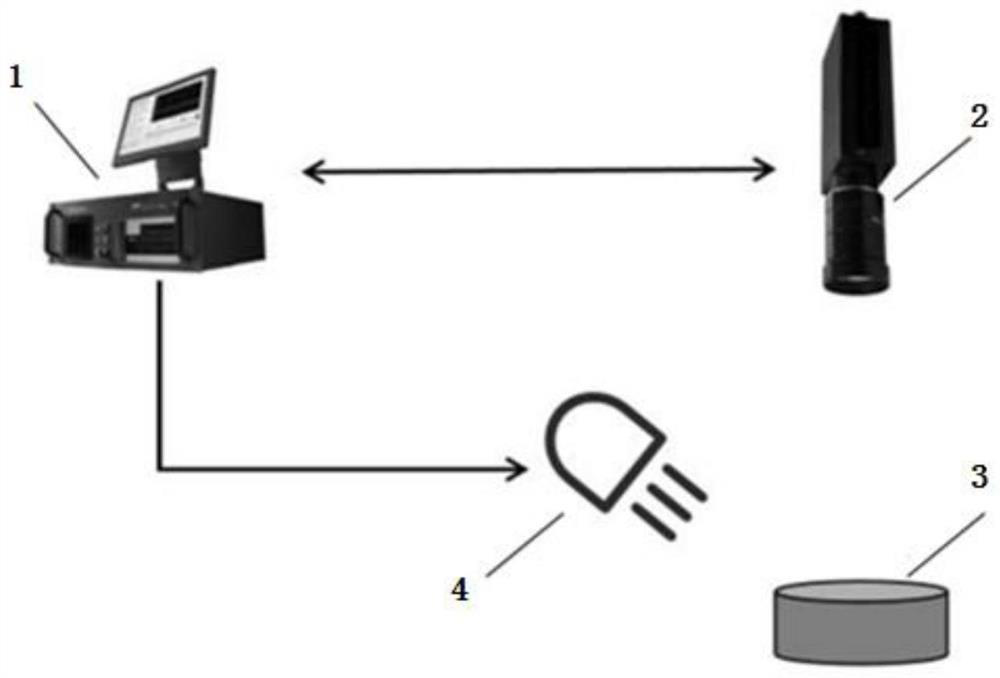

Machine vision light source system capable of automatically switching light source forms and dimming method

A technology of machine vision and light source system, which is applied in the direction of photo interpretation and camera equipment, can solve the problems of insufficient light source and frequent replacement of light source, and achieve the effect of improving efficiency and increasing the degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

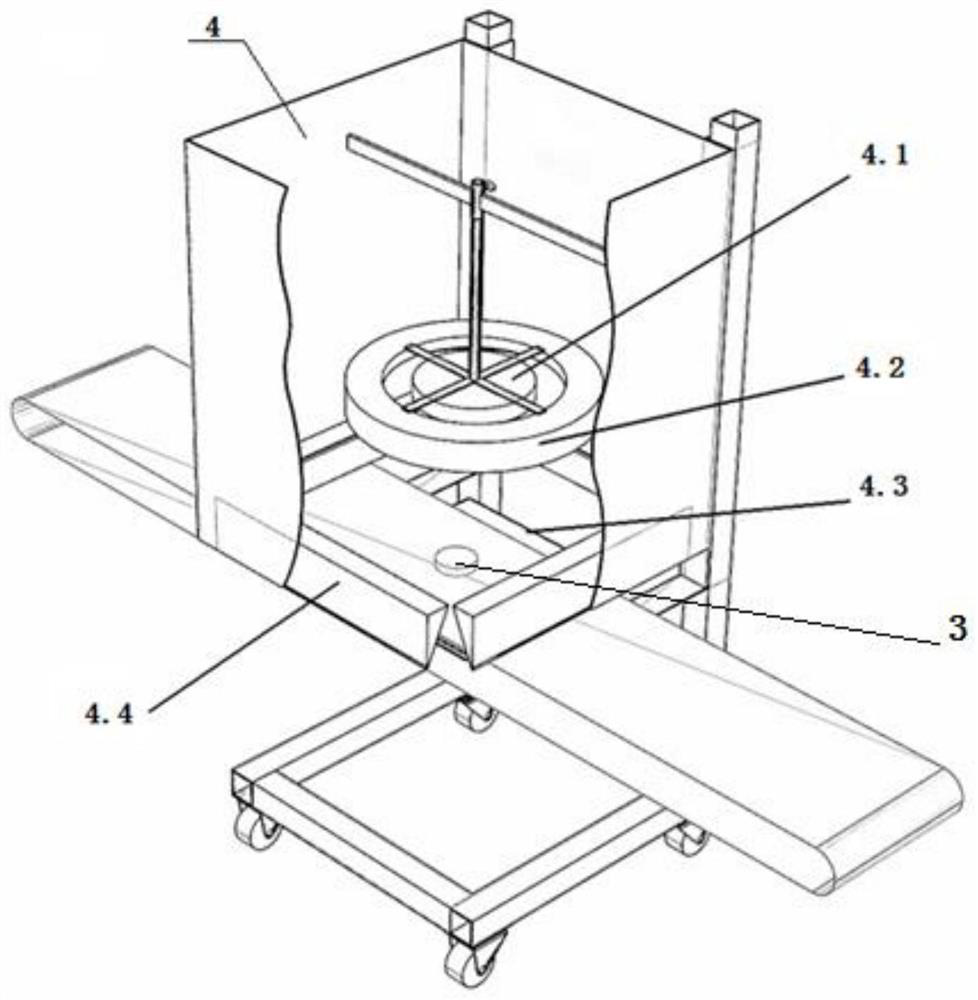

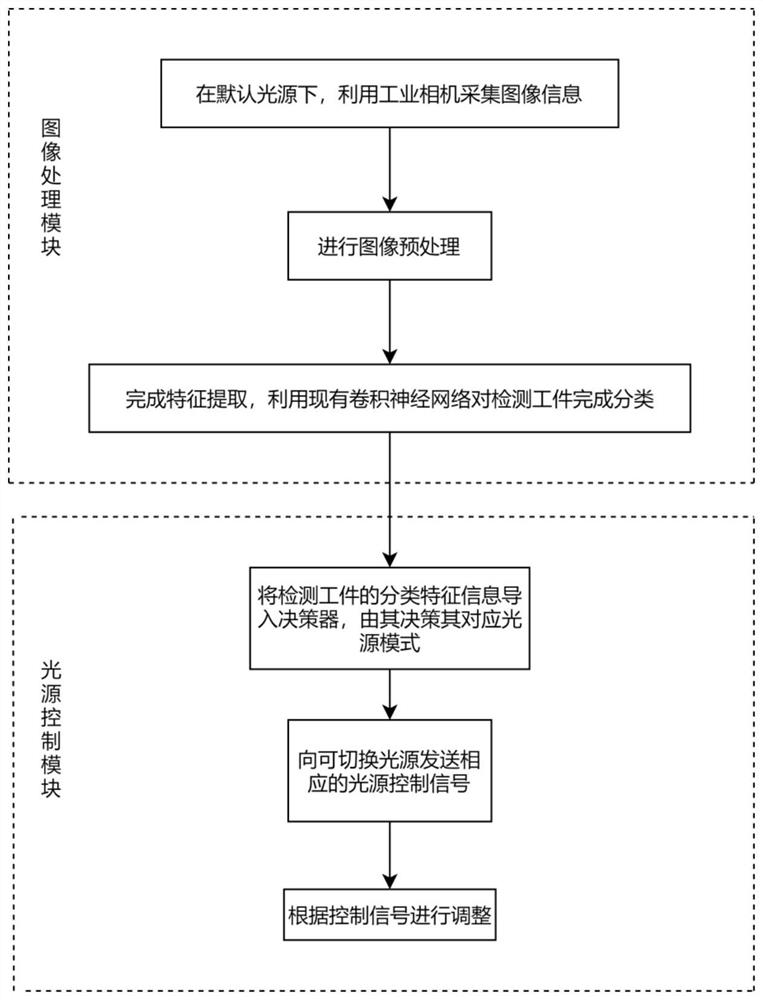

[0029] Example: detection of solder joints on the surface of the battery. The solder joints are located on the metal sheet. It is necessary to photograph and locate the solder joints to determine whether the solder joints are welded correctly. The steps of automatically switching the light source form: the battery workpiece is transported to the bottom of the light source device through the conveyor belt, the industrial camera 2 acquires images under the default light source, and transmits the pictures to the industrial computer 1, and the image processing module in the industrial computer 1 performs image preprocessing first, and then Use image recognition to perform feature extraction and classification of the obtained images. The classification labels of the obtained battery workpieces are strong reflection, smooth surface, and insufficient brightness. The type signal of the battery workpiece is imported into the decision maker for classification decisions, and high-angle ann...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com