Automatic calibration method for visual inspection system

An automatic calibration and visual inspection technology, applied in image data processing, instrumentation, calculation, etc., can solve the problems of inability to guarantee the consistency, accuracy and efficiency of calibration evaluation results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020]Embodiments will be described in detail below, and examples are illustrated in the drawings. The following description is related to the drawings, unless otherwise indicated, the same numbers in the drawings represent the same or similar elements. The embodiments described in the following examples do not represent all embodiments consistent with the present application. An example of a system and method consistent with some aspects of the present application is only in accordance with the claims.

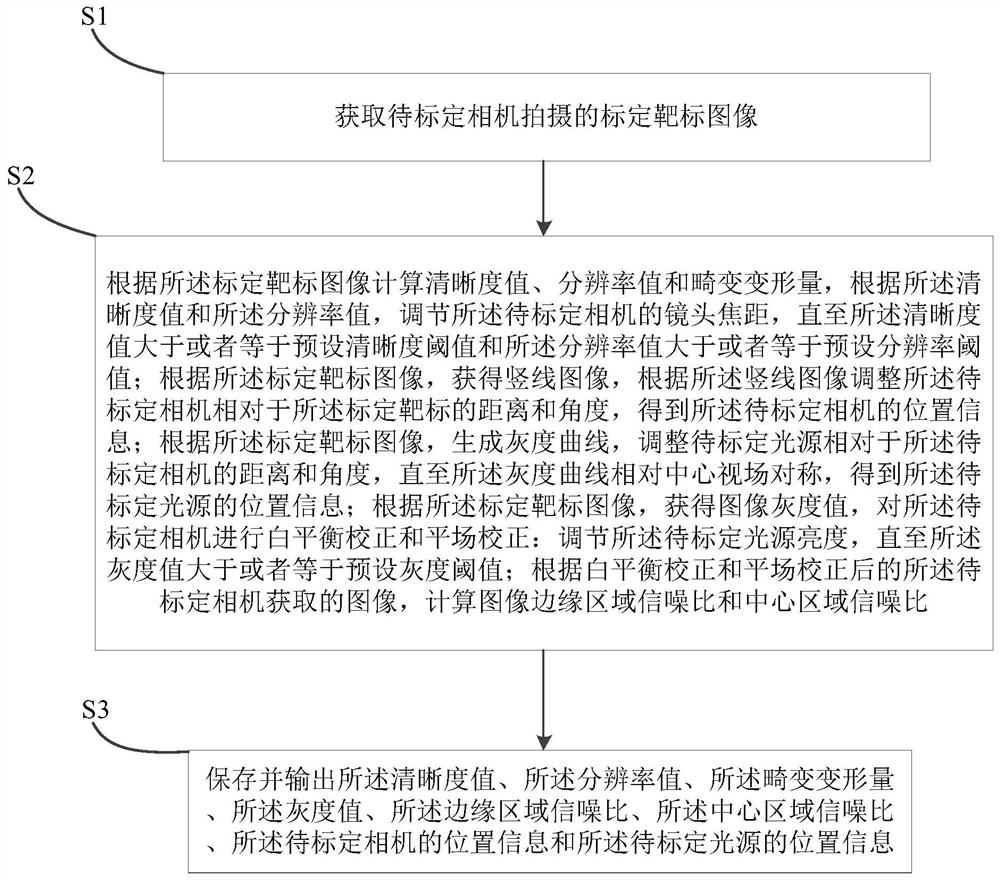

[0021]Seefigure 1,figure 1A flowchart of one embodiment of an automatic calibration method for a visual detection system is provided for the present application. This application provides an automatic calibration method for visual detection systems, including:

[0022]S1: Get the calibration target image to be taken to be calibrated; the calibration target image includes a pattern of different shapes, and the corresponding camera can be calibrated according to the different shapes.

[0023]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com