Additive manufacturing process

A technology of additive manufacturing and composition, applied in the field of additive manufacturing, can solve the problems of dimensional accuracy, dimensional accuracy, productivity and mechanical performance comparison

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

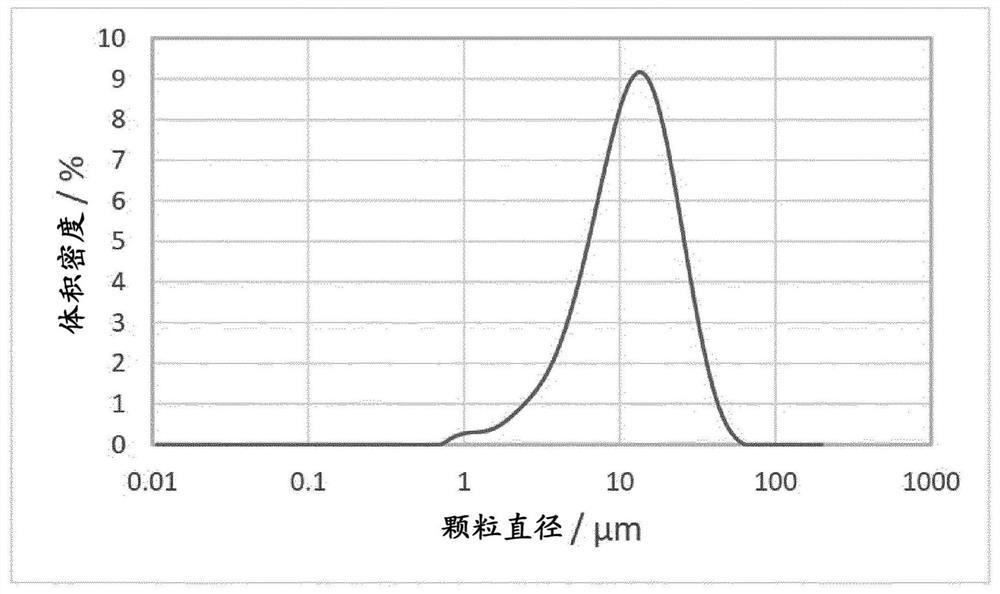

[0275] Rely on bead mills to grind glass flakes:

[0276] The grinding vessel of the mill (Dyno-mill multi Lab, Willy A. Bachofen AG Maschinenfabrik) was filled with 450 mL of grinding beads (soda lime glass, 0.75-1 mm). 100 g of ECR glass flake GF350 nmM without surface functionalization (from Glassflake Ltd., Leeds, UK) were dispersed in 1.5 L of water in a holding tank. A uniform dispersion is maintained by continuous agitation. The dispersion is pumped with a peristaltic pump to the grinding vessel and returned from the mill outlet to the storage tank. Once the particle diameter D 3,50 and D 3,99 When the desired value is reached, the milling is stopped.

[0277] To clean glass flakes:

[0278] When the unwashed glass flakes were added to dental compositions, a grayish paste was obtained. For better aesthetic results, the glass flakes can be cleaned before coating. For cleaning, the glass flakes can be stirred in twice the amount of 2.5% hydrochloric acid for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com