Method for detecting the trapping or twisting of a discharge pipe

A pipeline and detection system technology, applied in the field of pipeline extrusion, can solve problems such as expensive and complex pressure sensors, and achieve the effects of simplifying vehicles, simplifying structure, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

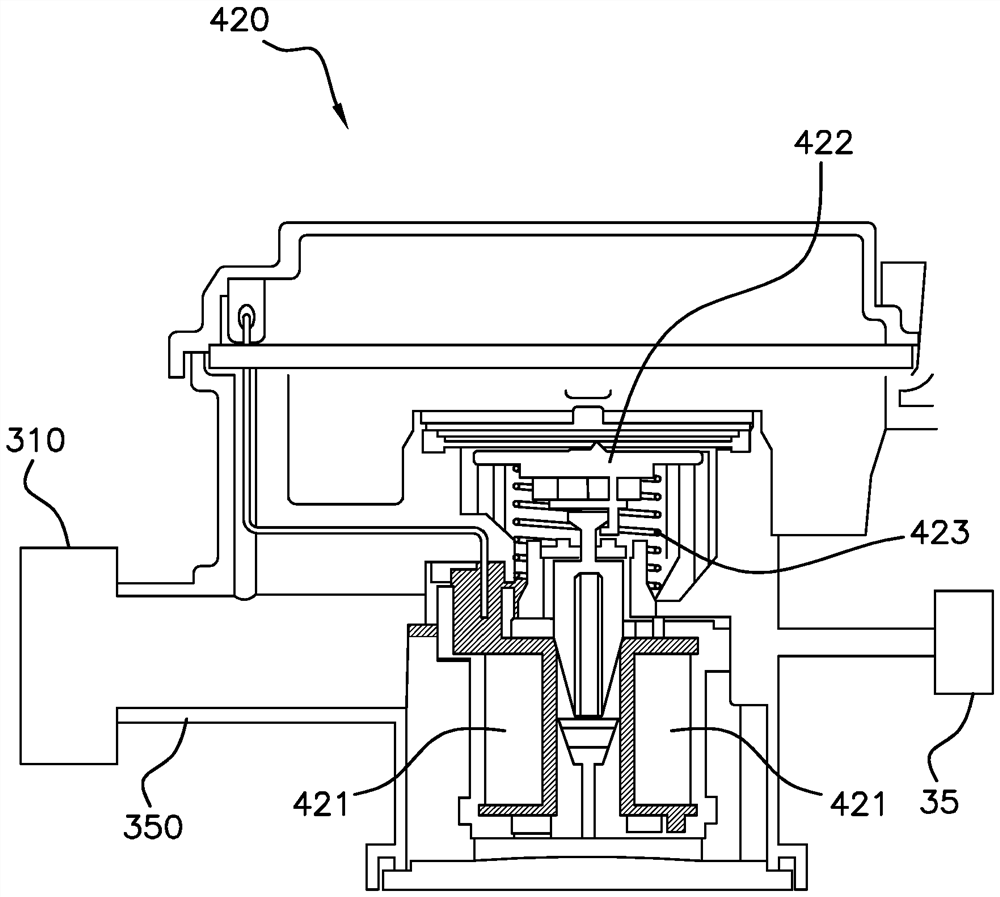

[0032] figure 1 A motor vehicle 1 is shown including an internal combustion engine 10 , a fuel tank 20 , an evaporation system 30 and a detection system 40 .

[0033] Internal combustion engine 10 (or internal combustion engine) includes one or more hollow cylinders 100, each cylinder defining a combustion chamber into which a mixture of air and fuel is injected.

[0034] Fuel, such as gasoline, is stored in fuel tank 20 from which fuel is drawn by injection pump 25 for delivery into cylinders 100 of engine 10 via injection rail 26 and injectors 27 .

[0035] Since it is necessary to control the pressure of the gas contained in the tank 20 in order to avoid any damage or accident and limit the pollution caused by the fuel vapors, the vehicle 1 includes an evaporation system 30 which is connected to the engine 10, the tank 20 and via air filtration Connected to the outside of the vehicle 1, the air filter 35 makes it possible to absorb the vapors and deliver them to the combus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com