2D and 3D combined sleeve cutting system and process for satellite type circular knife die cutting machine

A round die and combined sleeve technology, applied in metal processing and other directions, can solve the problems of long cutting distance, large dimensional changes, and low sleeve cutting accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

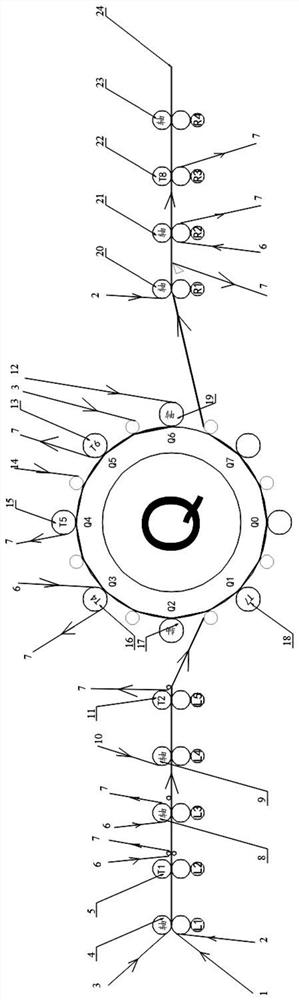

[0030] A 2D and 3D combined sleeve cutting system for a satellite-type circular knife die-cutting machine, characterized in that it includes a 2D primary sleeve cutting unit, a 3D sleeve cutting unit and a 2D secondary sleeve cutting unit, and the 2D primary sleeve cutting unit includes sequentially set The first pressing shaft 4, the first die-cutting tool 5, the second pressing shaft 9 and the second die-cutting tool 11; the 3D nesting unit includes a satellite workstation and counterclockwise sequentially arranged in the installation groove of the satellite workstation The third pressing shaft 19, the third die-cutting tool 13, the fourth die-cutting tool 15, the fifth die-cutting tool 16, the fifth die-cutting tool and the sixth die-cutti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com