Tunnel gravel transfer device and construction method thereof

A transfer device and crushing technology, which is applied in cleaning devices, transportation and packaging, loading/unloading, etc., can solve the problem of low transfer efficiency of crushed stones

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

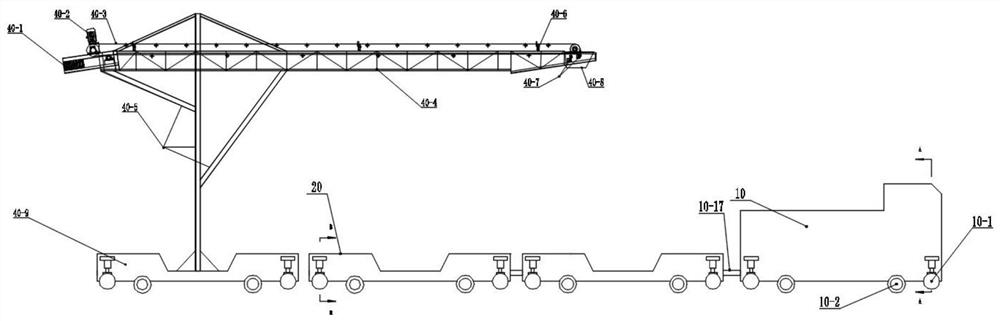

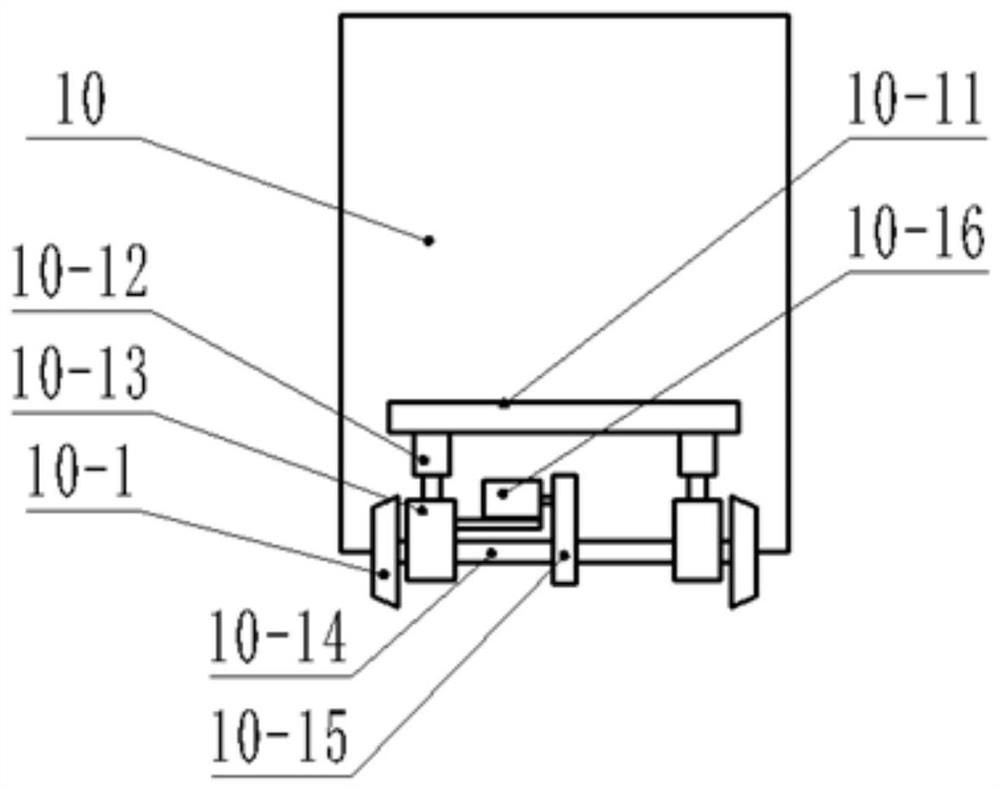

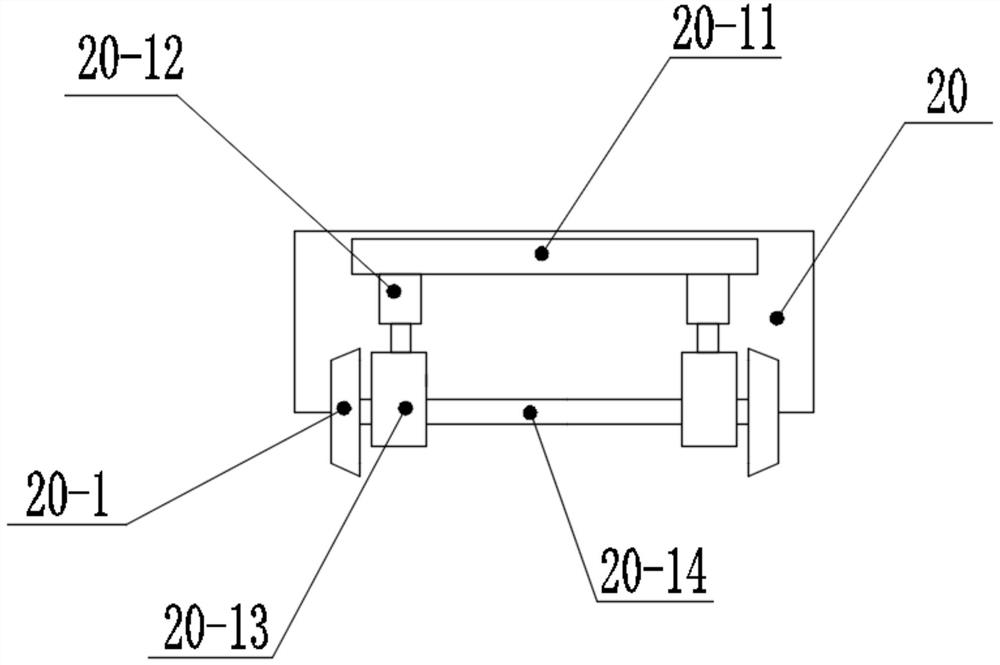

[0036] A tunnel gravel transfer device, comprising: a conveyor belt conveyor, one end of the conveyor belt conveyor is fixed with a belt conveyor fixing frame 40-5, and the bottom of the belt conveyor fixing frame 40-5 is fixed with a belt transport vehicle 40- 9. One end of the transport vehicle 40-9 is provided with a road-rail vehicle set.

[0037] In the above-mentioned first embodiment, the tunnel entrance is blasted by the drill and blast method, and the gravel falls on the tunnel face, and the steel rails are laid in the tunnel, and the belt transport vehicle carries the belt conveyor to move on the steel rails in the tunnel, and Move to the gravel place, and after the belt conveyor is in place, move the road-rail dual-purpose vehicle group to one end of the slag outlet of the belt conveyor through the rails to complete the positioning of the whole set of equipment; the excavator transfers the gravel to the belt conveyor, and the belt conveyor The gravel is transferred ...

Embodiment 2

[0039] Embodiment two: one end of the transport belt conveyor is fixedly provided with a counterweight (40-1); the counterweight fixedly provided at one end of the belt conveyor, its weight is based on the gravel weight dug out by the excavator each time and the weight of the belt conveyor. The moment arm is calculated, and the calculated counterweight is installed on one end of the belt conveyor to keep the two ends of the belt conveyor balanced during the operation.

Embodiment 3

[0040] Embodiment 3: The end of the transport belt conveyor 40 away from the counterweight 40-1 is provided with several anti-deflection rollers 40-6; the anti-deflection rollers are installed on both sides of the belt conveyor, which can effectively control the left and right sides of the belt conveyor. Offset, up and down fluctuations and so on.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com