Non-Newtonian fluid wharf fender device

A non-Newtonian fluid and dock fender technology, applied in the field of non-Newtonian fluid dock fender devices, can solve the problems of poor buffering effect, permanent damage to the dock structure, and the service life cannot reach the design period, and achieve the effect of reducing the reaction force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

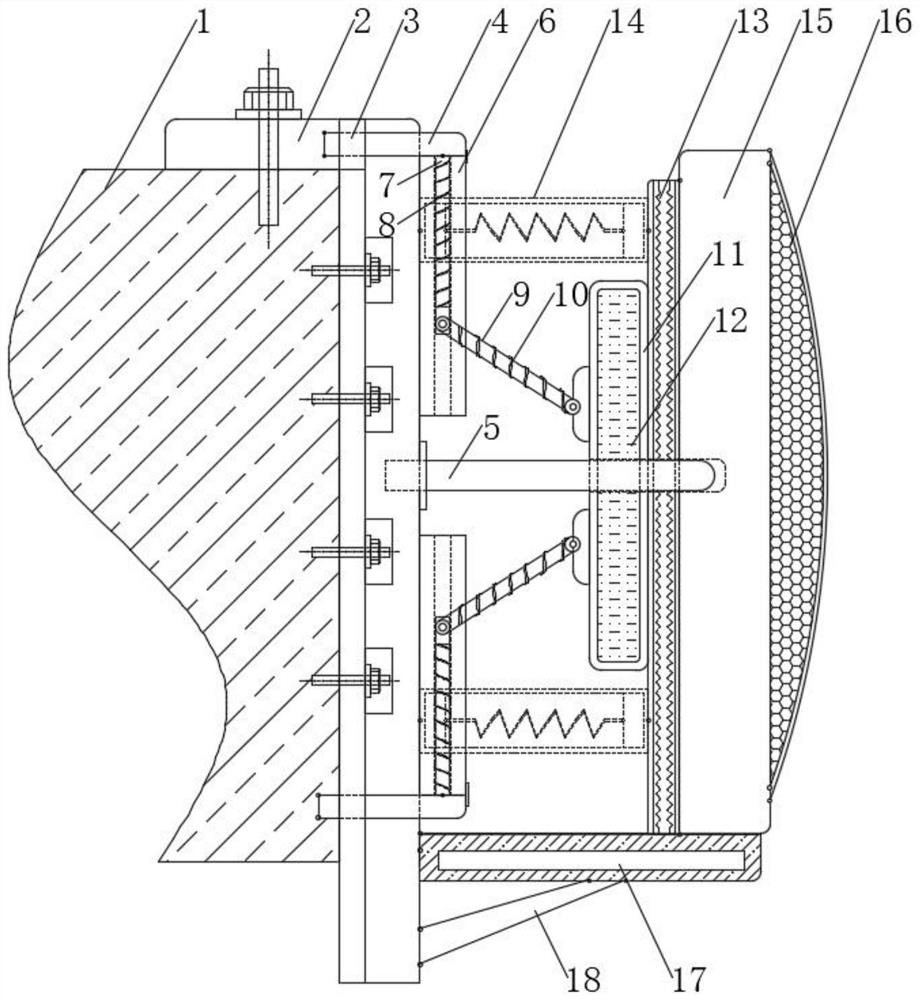

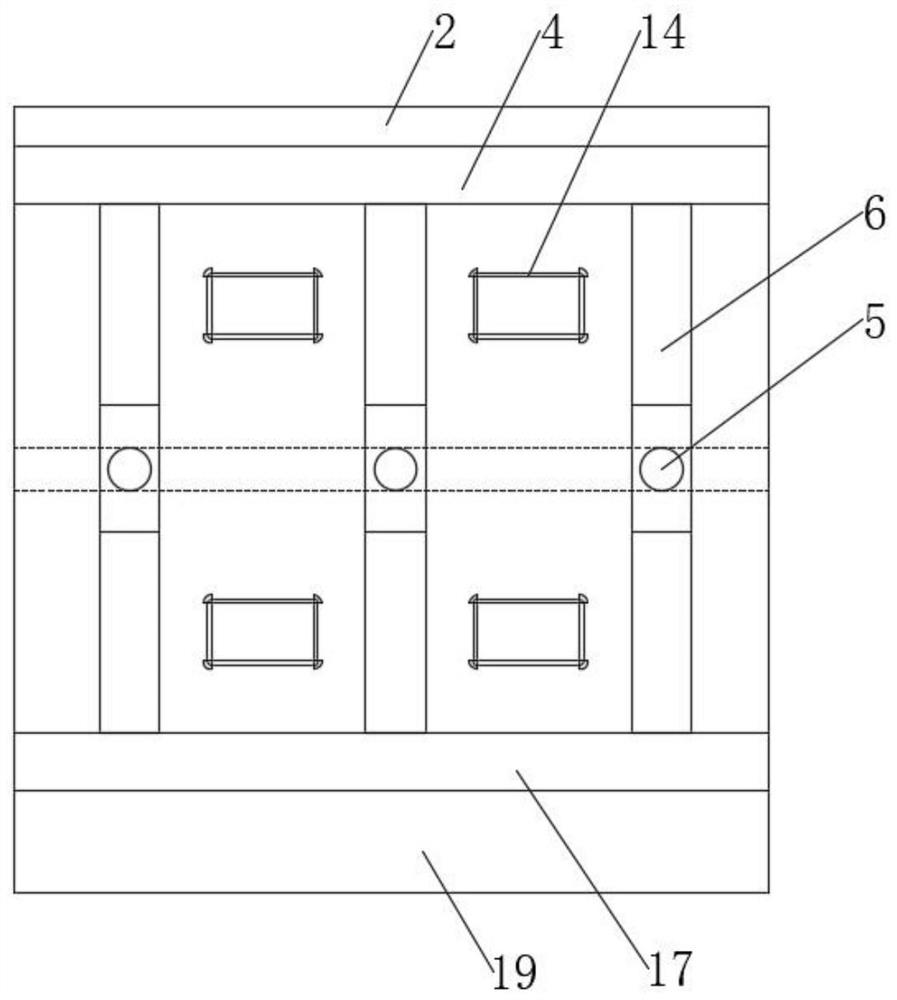

[0014] see figure 1 and figure 2 , the present embodiment provides a non-Newtonian fluid wharf fender device, comprising a fender base 2, a rubber bag 11 and an anti-collision rubber 15, the rubber bag 11 is provided with a non-Newtonian fluid layer 12, a non-Newtonian fluid layer 12 The filler used is polyethylene, polyacrylamide or polyvinyl chloride. Due to the non-linear relationship between the shear stress and the shear strain rate of the non-Newtonian fluid, the non-Newtonian fluid will produce viscous characteristics when subjected to force. Using this The viscous property is used to deal with the collision impact brought by the berthing ship. When the impact force is small, the viscosity of the non-Newtonian fluid is weak, and when the impact force is large, the viscosity of the non-Newtonian fluid is strong.

[0015] A mounting base 3 is provided between the fender base 2 and the wharf parapet 1, and the mounting base 3 is fixedly connected with the fender base 2 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com