Heat energy circulation baking equipment for electronic components

A technology for electronic components and baking equipment, applied in lighting and heating equipment, drying, drying machines, etc., can solve the problems of low oven space utilization, reduced baking effect, increased oven humidity, etc., to reduce heat Dissipation, saving time to take parts, weakening the effect of air convection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

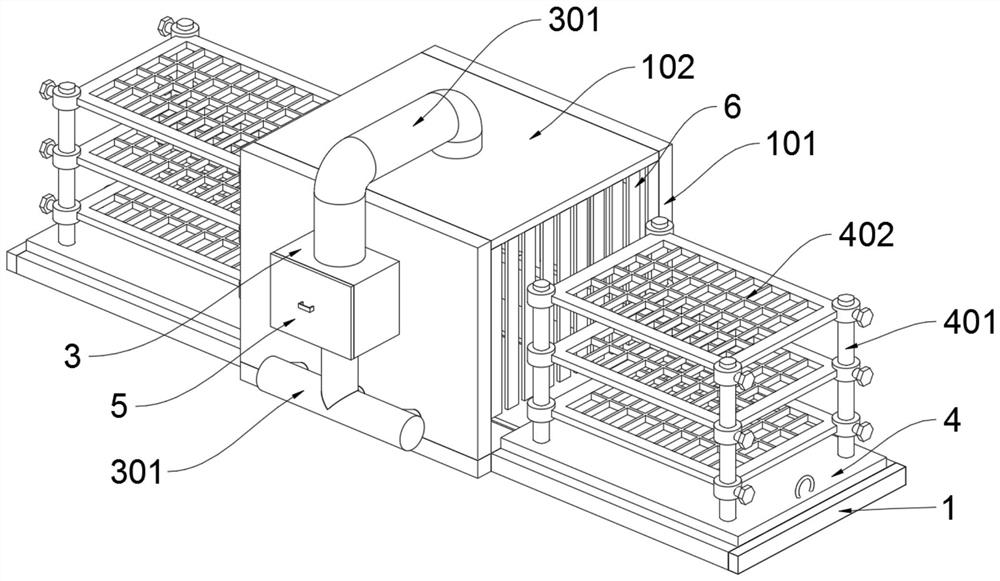

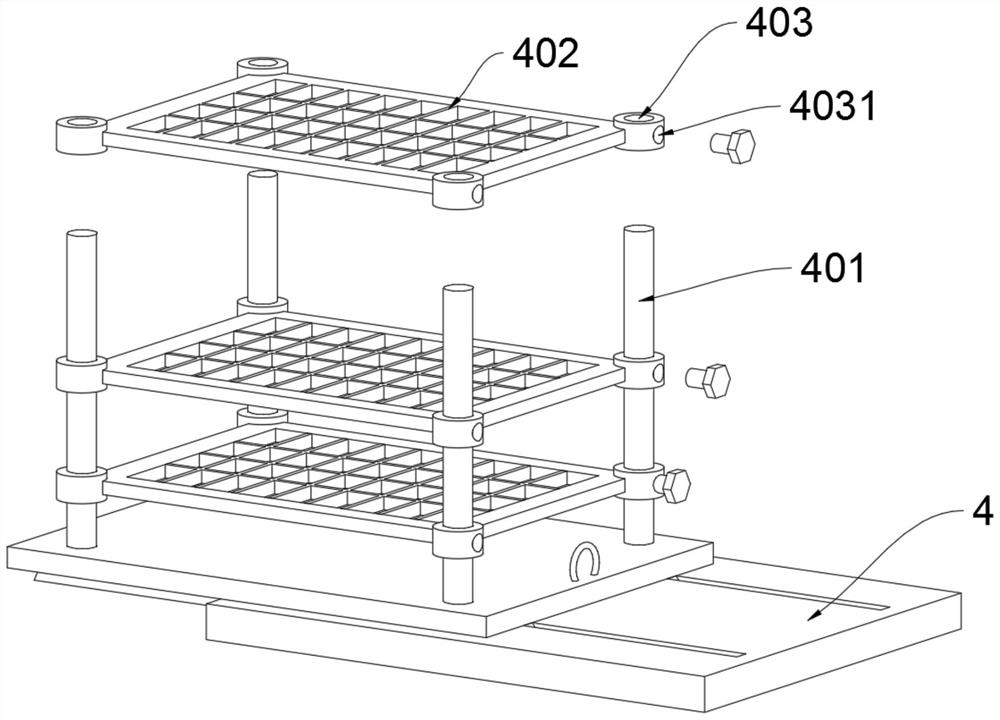

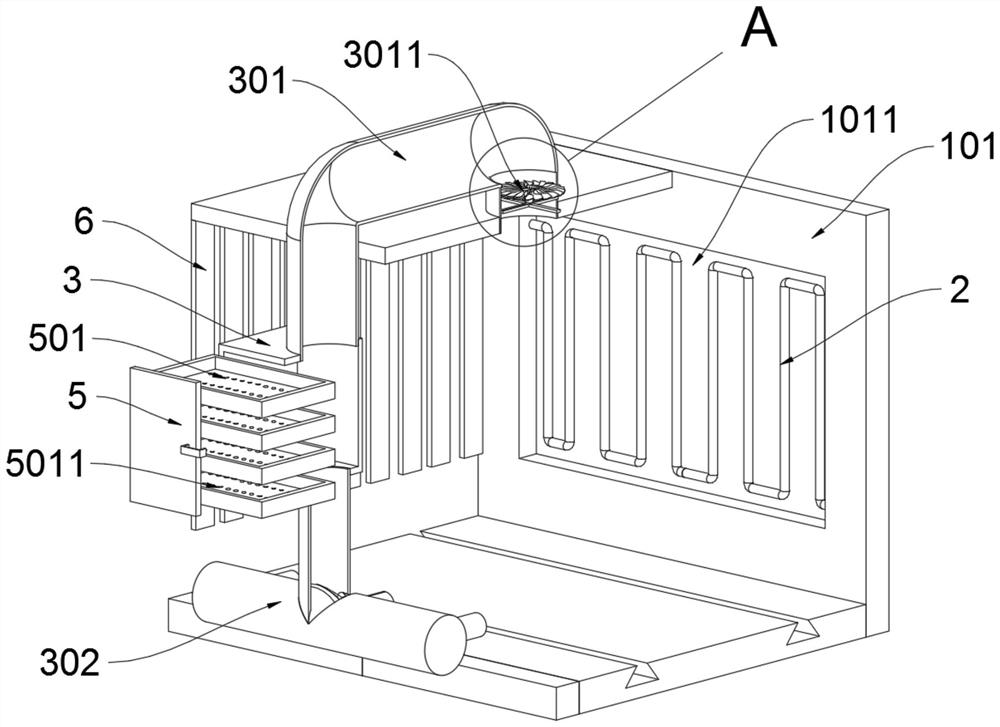

[0031] as attached figure 1 to attach Figure 6 Shown:

[0032] The present invention provides a heat cycle baking equipment for electronic components, which includes a bottom plate 1 and a sliding plate 4; two sets of track grooves 103 are symmetrically arranged on the upper end surface of the bottom plate 1, and two sets of side rail grooves 103 are symmetrically arranged on the left and right sides of the bottom plate 1. Plate 101, the top of two groups of side plates 101 is fixedly connected with the top plate 102; the upper end of the top plate 102 is provided with a suction pipe 301, and the inside of the suction pipe 301 is provided with a fan 3011; the suction pipe 301 is fixedly connected with the drying box 3, and the drying box 3 The lower end is provided with an air intake pipe 302; the sliding plate 4 is slidingly mounted inside the track groove 103 on the upper surface of the base plate 1; the upper end surface of the sliding plate 4 is symmetrically provided wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com