Inertial navigation pose precision adjusting and mounting device for unmanned aerial vehicle

A technology for installing devices and UAVs, which is applied in aircraft assembly, measuring devices, instruments, etc., and can solve problems such as inability to meet UAV inertial navigation installation accuracy measurement requirements, low measurement devices, and short UAV assembly cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

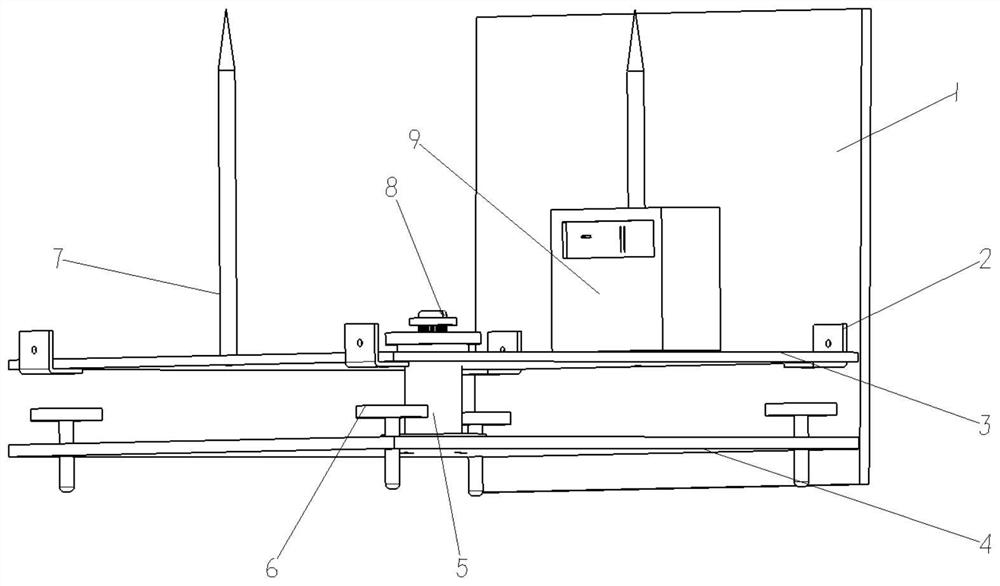

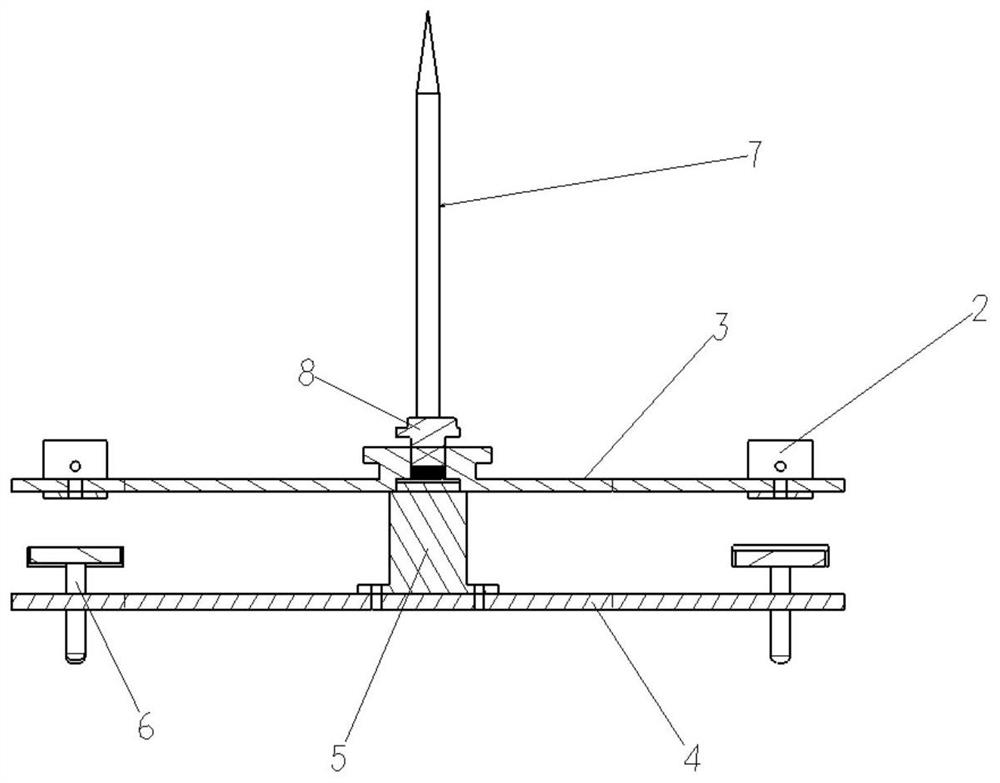

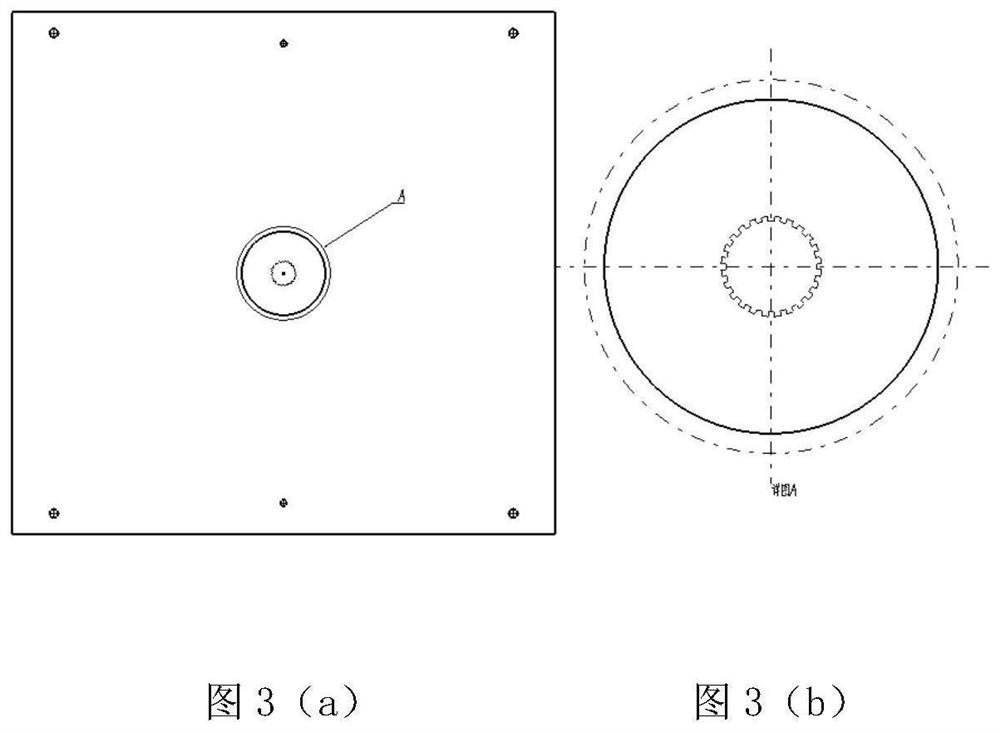

[0032] This embodiment is an installation device for adjusting the pose accuracy of UAV inertial navigation.

[0033] refer to Figure 1 to Figure 7 , the present embodiment is used for the UAV inertial navigation position and attitude adjustment installation device, which consists of a fuselage frame plate 1, a connecting joint 2, an inertial navigation installation template 3, a bottom plate 4, a connecting column 5, a horizontal adjustment screw 6, and a heading indicator rod 7. The course adjustment rod 8, the electronic level 9, the optical level 10 and the optical theodolite 11 are composed; wherein, the inertial navigation installation template 3 is located at the upper end of the connecting column 5, and the inertial navigation installation template 3 and the connecting column 5 are clearance fit, which can Rotate around connecting column 5. The bottom plate 4 is fixedly connected with the bottom surface of the connecting column 5 by bolts. The contour dimensions of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com