Anti-vibration area array sweep frequency measurement device and method

A measurement device and frequency sweeping technology, which is applied in the direction of measurement devices, optical devices, radio wave measurement systems, etc., can solve problems such as unavoidable vibration and temperature fluctuations, and low measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

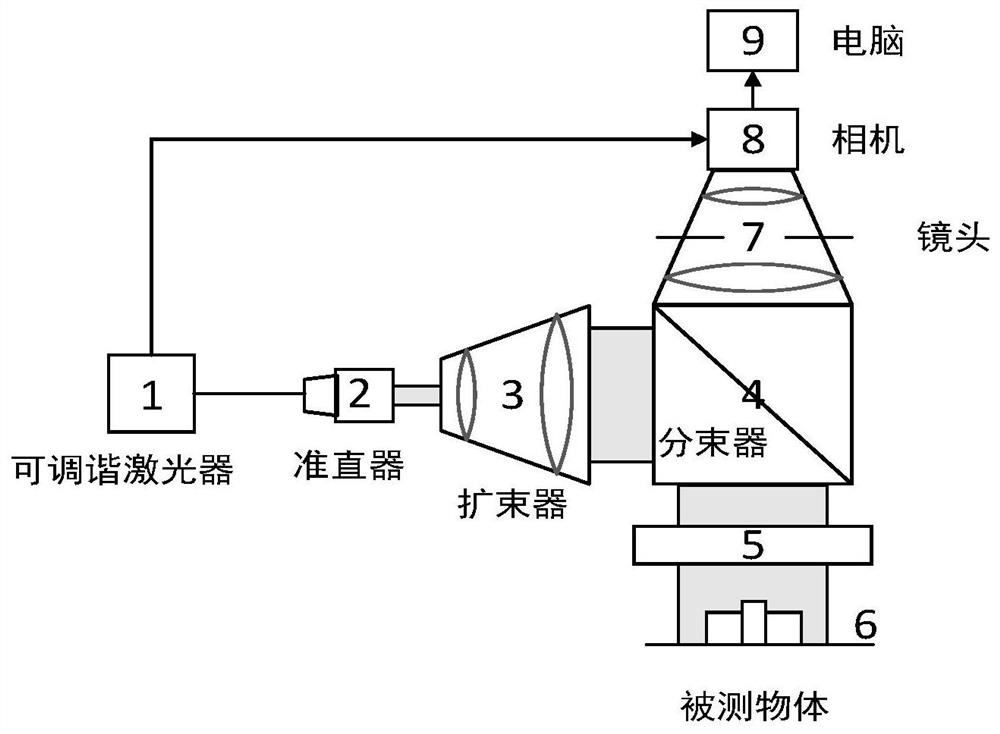

[0046] Such as figure 1 An anti-vibration type area array frequency sweep measurement device is provided as shown, including a tunable laser 1, a collimator 2, a beam expander 3, a beam splitter 4, a reflective element 5, a lens 7, a camera 8 and a computer 9;

[0047] A collimator 2, a beam expander 3, and a beam splitter 4 are sequentially arranged in the transmission direction of the original beam; a reflective element 5, a beam splitter 4, and a lens 7 are sequentially arranged in the direction in which the original beam is reflected by the beam splitter 4 and the camera 8; the output end of the tunable laser 1 is connected to the input end of the camera 8; the measured object 6, the reflective element 5 and the beam splitter 4 are sequentially connected through a rigid structure;

[0048] The process of changing the wavelength of the output wavelength of the tunable laser 1 with time is called optical frequency scanning, referred to as frequency sweeping; A trigger signa...

Embodiment 2

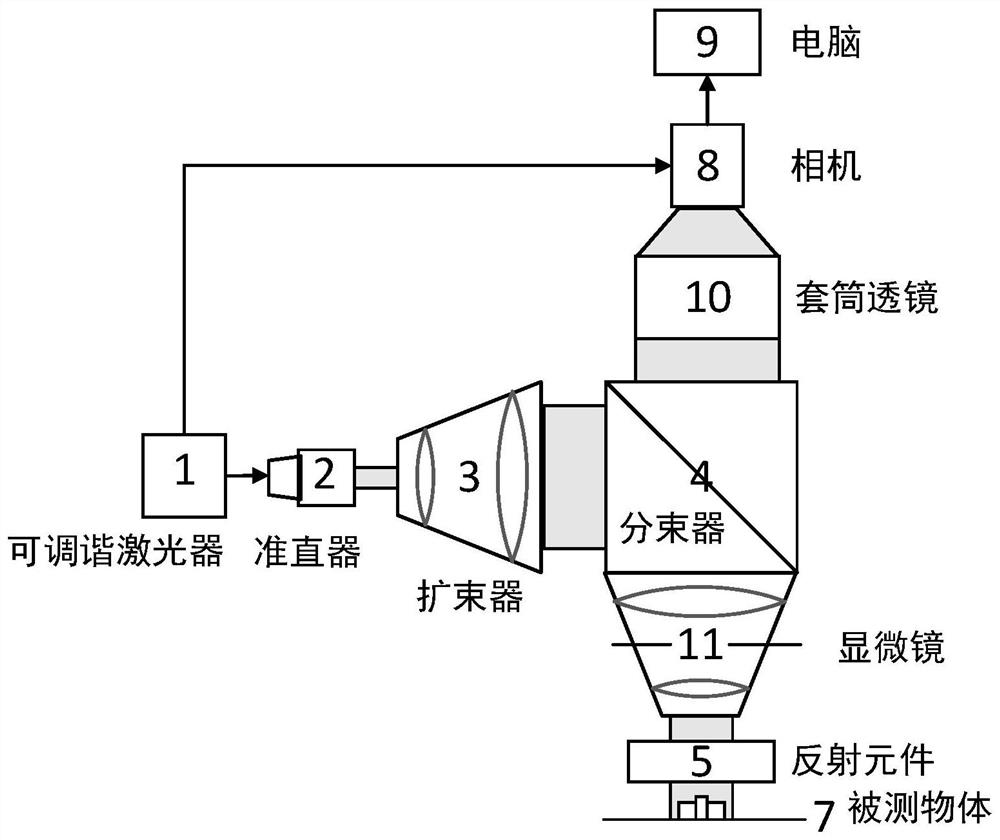

[0059] Such as figure 2 As shown, an anti-vibration area array frequency sweep measurement device is provided, including a tunable laser 1, a collimator 2, a beam expander 3, a beam splitter 4, a reflective element 5, a microscope 11, a tube lens 10, and a camera 8 and computer 9;

[0060] A collimator 2, a beam expander 3, and a beam splitter 4 are sequentially arranged in the transmission direction of the original beam; a reflective element 5, a microscope 11, and a beam splitter 4 are sequentially arranged in the direction in which the original beam is reflected by the beam splitter 4 , a sleeve lens 10 and a camera 8; the output end of the tunable laser 1 is connected to the input end of the camera 8; the measured object 6, the reflective element 5 and the microscope 11 are sequentially connected through a rigid structure;

[0061] The process of changing the wavelength of the output wavelength of the tunable laser 1 with time is called optical frequency scanning, referr...

Embodiment 3

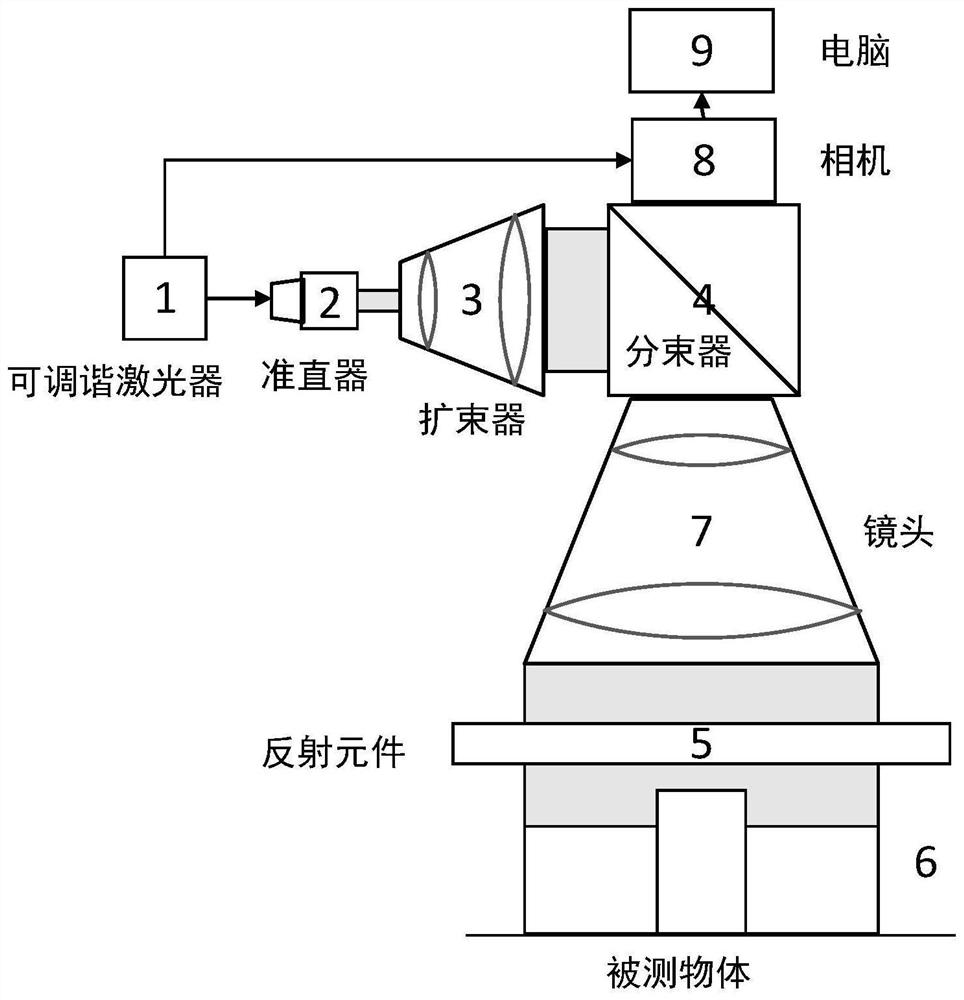

[0065] Such as figure 1 An anti-vibration type area array frequency sweep measurement device is provided as shown, including a tunable laser 1, a collimator 2, a beam expander 3, a beam splitter 4, a reflective element 5, a lens 7, a camera 8 and a computer 9;

[0066] A collimator 2, a beam expander 3, and a beam splitter 4 are sequentially arranged in the transmission direction of the original beam; a reflective element 5, a lens 7, and a beam splitter 4 are sequentially arranged in the direction in which the original beam is reflected by the beam splitter 4 and the camera 8; the output end of the tunable laser 1 is connected to the input end of the camera 8; the measured object 6, the reflective element 5 and the beam splitter 4 are sequentially connected through a rigid structure;

[0067] The process of changing the wavelength of the output wavelength of the tunable laser 1 with time is called optical frequency scanning, referred to as frequency sweeping; A trigger signa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com