A multi-installation optical fiber fast connector

An installation method and connector technology, applied in the direction of optical waveguide coupling, etc., can solve problems such as the complex structure of the gland end and the ceramic head end, the inability to disassemble, troublesome optical fiber connection, etc., and achieve good optical fiber drop-off performance, good The effect of replaceability and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

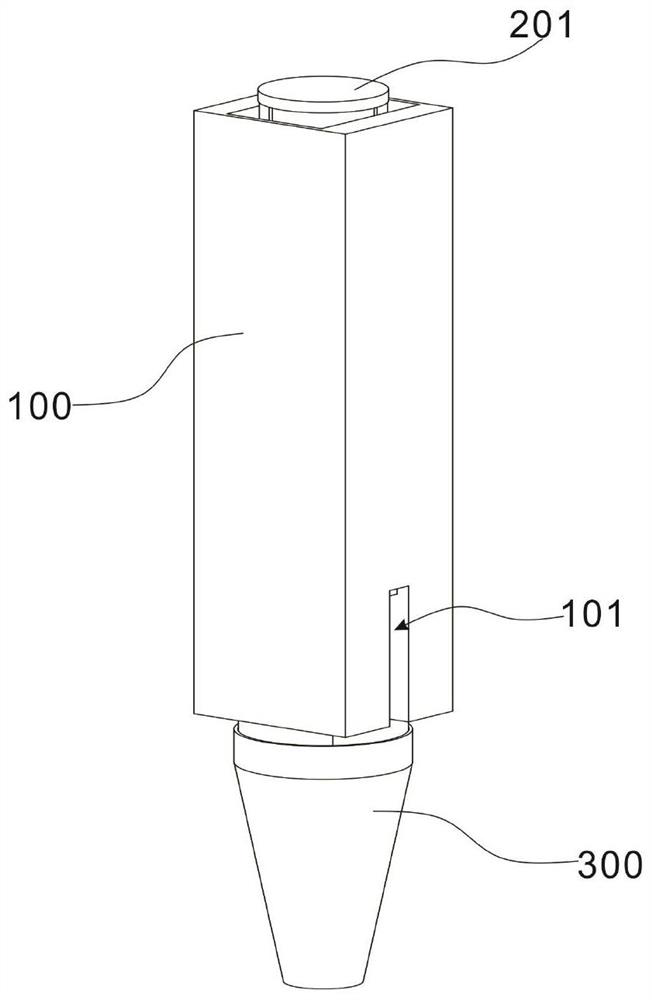

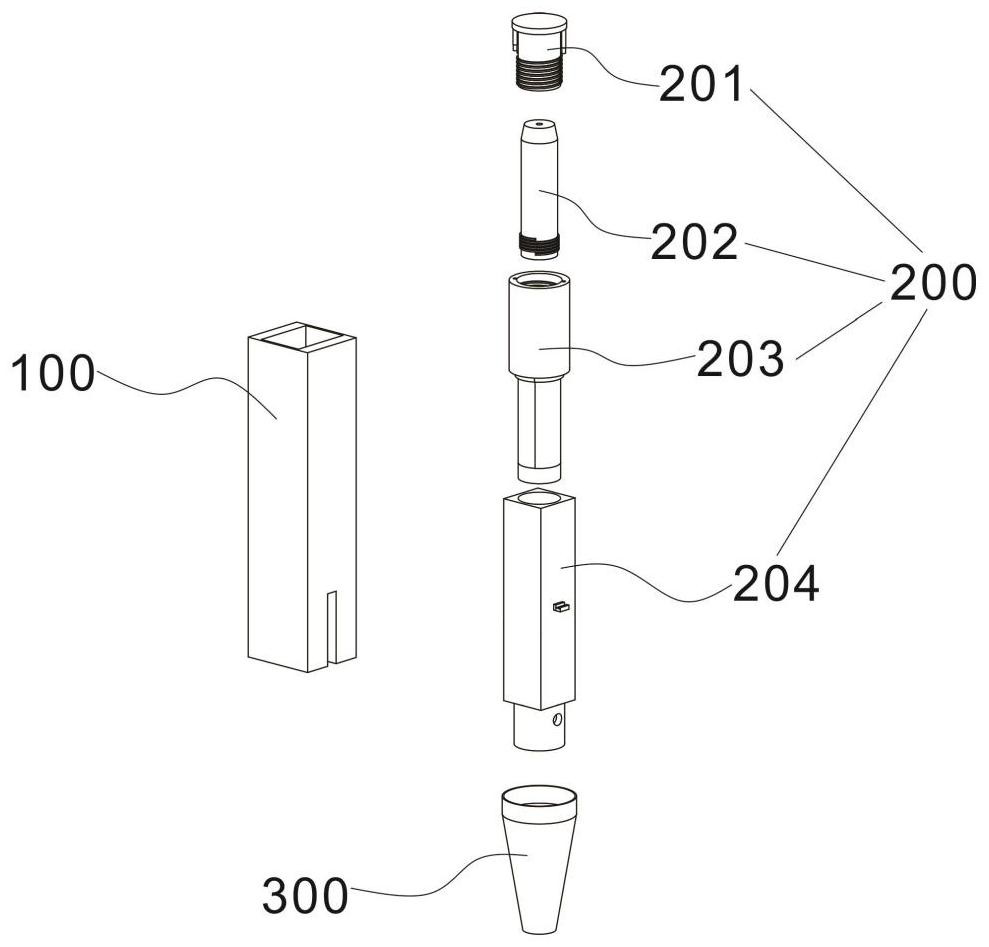

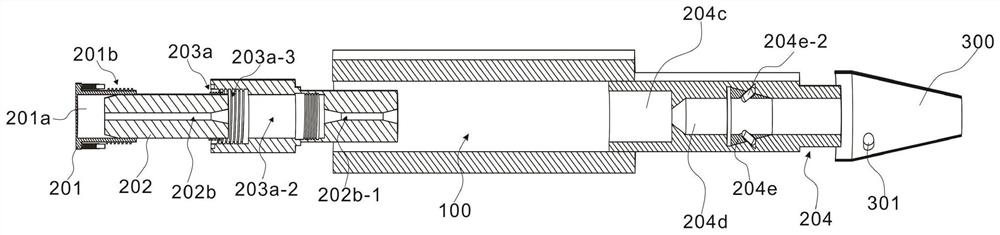

[0034] refer to Figure 1-8 , provides a schematic diagram of the overall structure of a fiber optic fast connector with multiple installation methods, such as figure 1 , 2 , a multi-installation optical fiber quick connector includes a housing 100, the bottom of the housing 100 is provided with an opening 101 extending to the top of the housing 100, and the bottom of the housing 100 at the opening 101 is provided with a special-shaped end; an optical fiber connection assembly 200; an optical fiber connection The assembly 200 includes a ceramic head 201, a fiber guide head 202, a rotating catheter 203, and a sealing protection sleeve 204. The sealing protection sleeve 204 is provided with a card interface 204a matched with a special-shaped end and a snap-in connection mirrored on the sealing protection sleeve 204. The hole 204b; and; the tail cover 300, the mirror image of the tail cover 300 is provided with the snap joint 301, and the snap joint 301 is mated with the snap co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com