Anti-adhesion spatula based on thermal expansivity

A thermal expansion, anti-adhesion technology, applied in the field of kitchen utensils, can solve the problems of inability to stick ingredients, inconvenient loading, and slow cooking time for ingredients.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

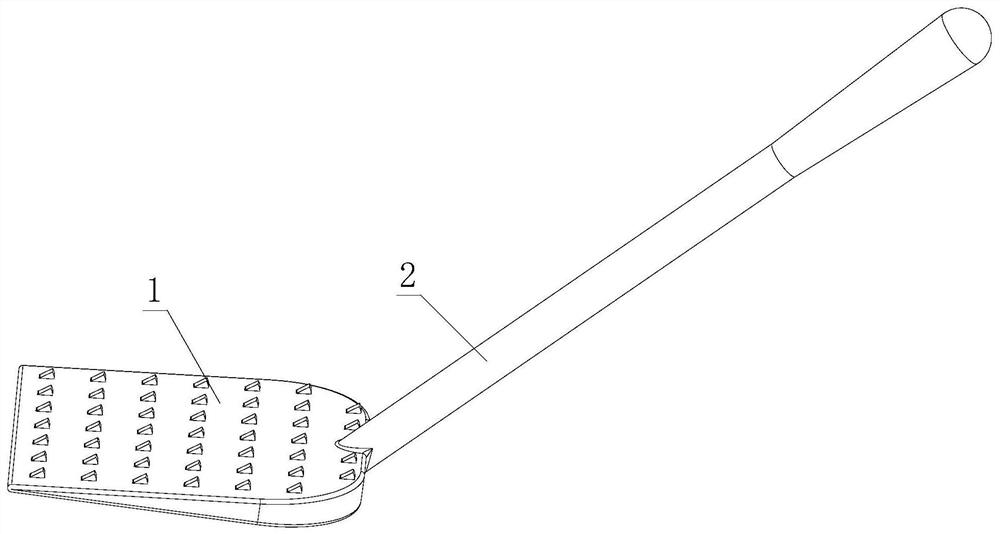

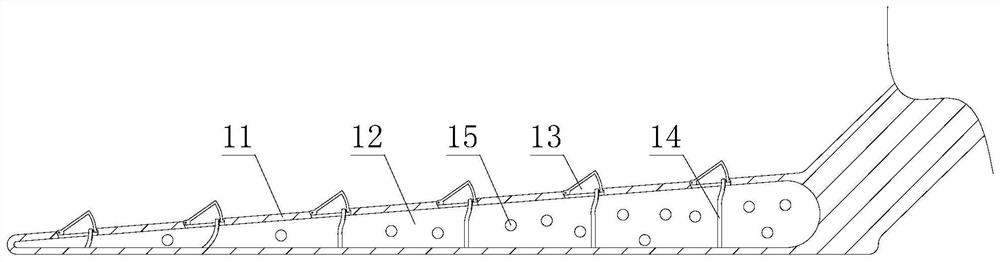

[0025] Such as figure 1 - figure 2 As shown, the present invention provides a kind of anti-adhesion spatula based on thermal expansion, comprising a shovel body 1, one side of the upper end of the shovel body 1 is fixedly connected with a handle 2, the inside of the shovel body 1 is provided with a shovel shell 11, the shovel shell The inside of 11 is provided with an inner chamber 12, the upper end of the shovel shell 11 is hingedly connected and closely fitted with an anti-adhesion structure 13, and a toggle lever 14 is arranged below the anti-adhesion structure 13, and the lower end of the toggle lever 14 is connected to the bottom of the shovel shell 11. The inner lower end is fixedly connected, and the number of anti-adhesion structures 13 provided on the shovel shell 11 is more than four, and a vibrating ball 15 is arranged between two adjacent toggle rods 14 in the inner cavity 12 .

[0026] In this embodiment, through the setting of the toggle lever 14, the anti-adhe...

Embodiment 2

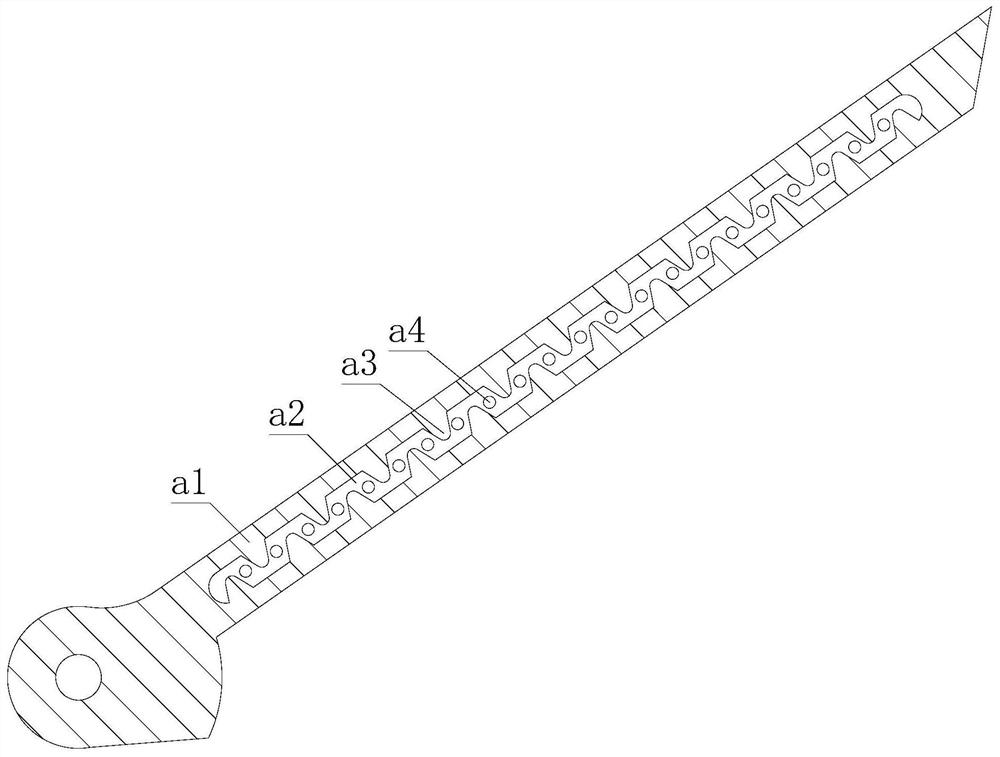

[0028] Such as Figure 3-4 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: the upper end of the anti-adhesion structure 13 is provided with an upper end shell a1, and the inside of the upper end shell a1 is provided with a vibration cavity a2, and the inside of the vibration cavity a2 is provided with a vibration The block a3, the upper shell a1 and the vibration block a3 are integrally designed, and the inside of the vibration chamber a2 is located between two adjacent vibration blocks a3, and an impact ball a4 is arranged.

[0029] Wherein, a side shell s1 is arranged inside the vibrating block a3, and a raised rubber pad s2 is fixedly connected to the upper end of the side shell s1, and a top block s4 is set on the side of the side shell s1 away from the raised rubber pad s2, and the side shell s1 and the top A concave rubber pad s3 is fixedly connected between the blocks s4, and a resilient sheet s5 is fixedly connected between ...

Embodiment 3

[0032] Such as Figure 5-6 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: preferably, the side of the anti-adhesion structure 13 is provided with a side end shell e1, and the inside of the side end shell e1 is provided with a sloshing cavity e2, and the sloshing cavity e2 A moving ball e3 is arranged inside the side end shell e1, and a toggle block e4 is fixedly connected to the lower end of one side of the side end shell e1. The side shell e1 vibrates.

[0033] Wherein, the inside of the moving ball e3 is provided with a shock shell w1, the inner wall of the shock shell w1 is fixedly connected with a shock plate w3, and the middle part of the shock shell w1 is provided with a middle ball w2.

[0034]In this embodiment, by setting the moving ball e3, the center of gravity of the anti-adhesion structure 13 can be changed when the mobile ball e3 moves, so that one side of the anti-adhesion structure 13 is heavier, so that the part o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com