Antirust treatment device for elevator part machining

A technology for anti-rust treatment and parts, which is applied in the direction of spraying devices, etc., can solve the problems of parts corrosion, affect the reliability of elevators, and the inability to achieve uniform painting, etc., to achieve good user experience, improved painting adequacy, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

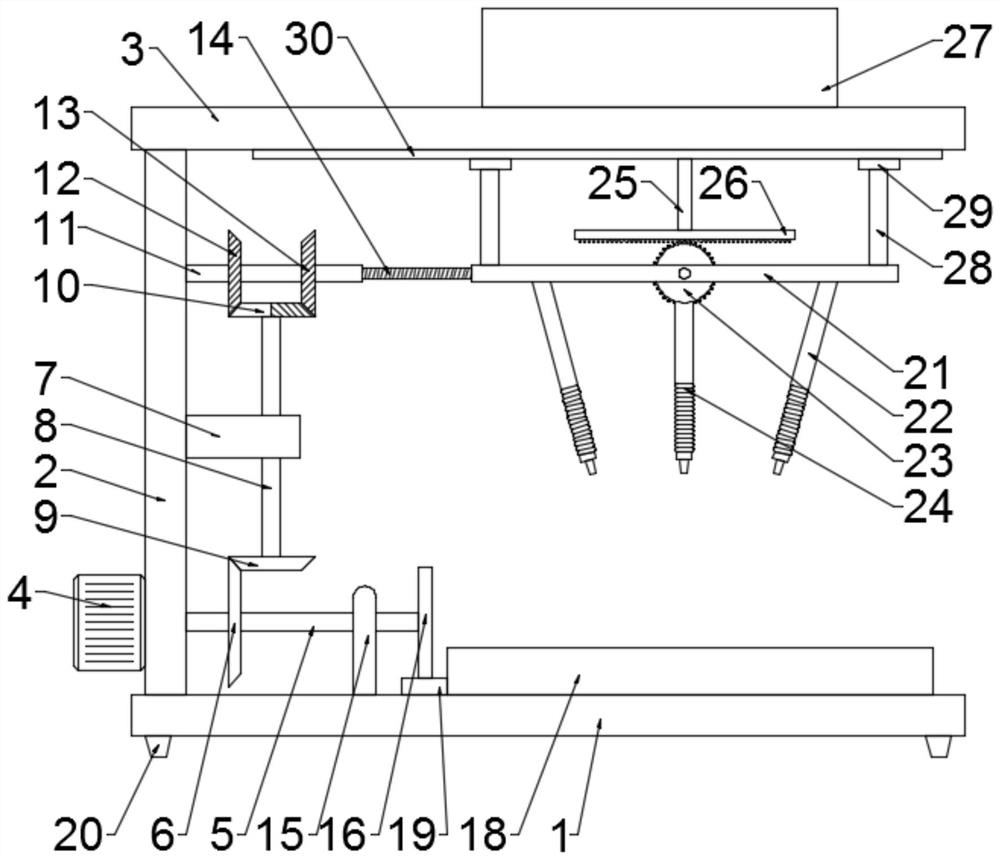

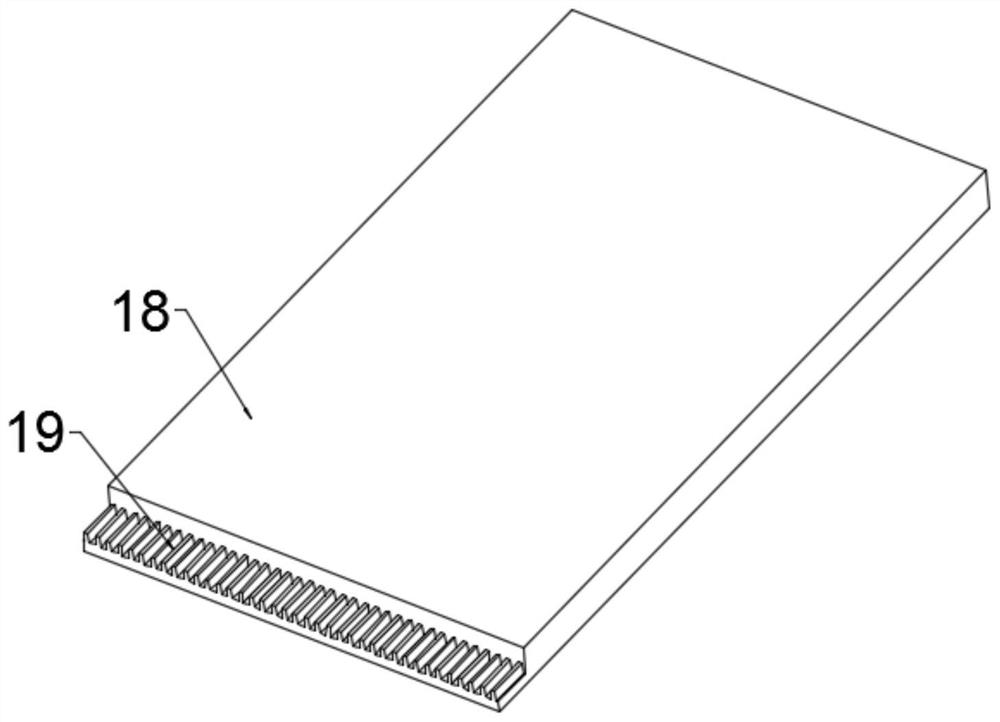

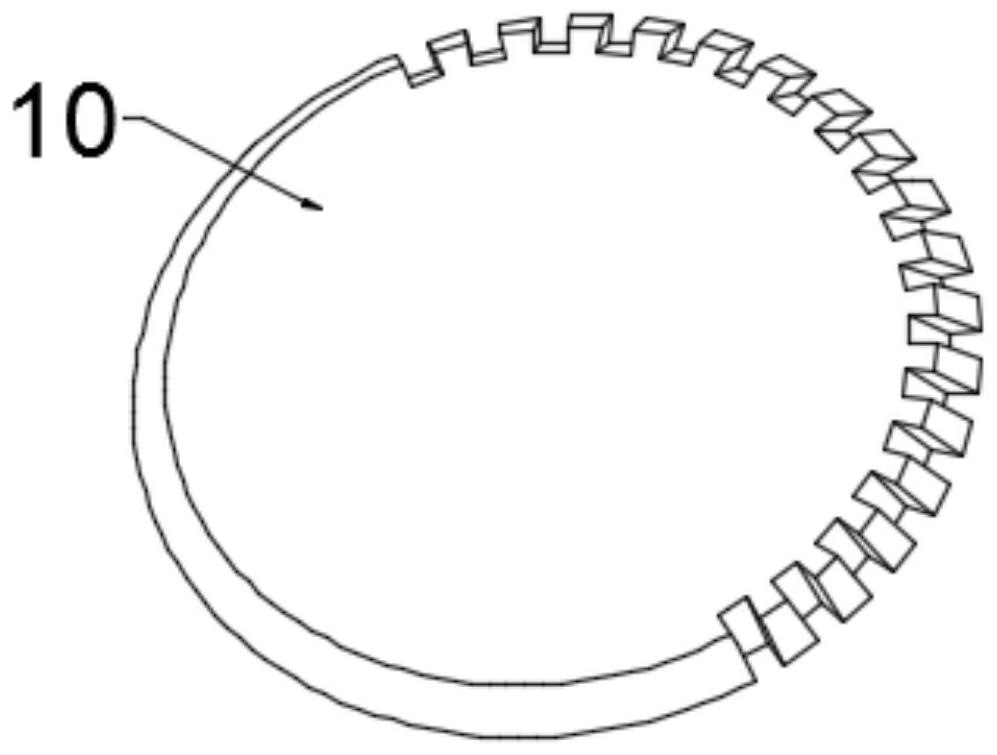

[0025] Example 1: Please refer to Figure 1-4 , an antirust treatment device for elevator parts processing, comprising a fixed base 1, a column 2 is fixedly connected to the left side above the fixed base 1, an upper beam 3 is fixedly connected to the top of the column 2, and an upper beam 3 is fixedly connected to the bottom left side of the column 2. The motor 4 is fixedly connected to the output shaft of the motor 4 with a drive shaft 5, the outside of the drive shaft 5 is fixedly connected with a first bevel gear 6, the right side of the column 2 is fixedly connected with a guide bracket 7, and the inside of the guide bracket 7 is rotatably connected with a transmission shaft 8. The bottom of the transmission shaft 8 is fixedly connected with a second bevel gear 9, the second bevel gear 9 meshes with the first bevel gear 6, and the top of the transmission shaft 8 is fixedly connected with an incomplete bevel gear 10;

[0026] Turn on the motor 4 during use, the rotation of...

Embodiment 2

[0039] Embodiment 2: This embodiment is a further improvement of the previous embodiment: a sliding guide rod 28 is fixedly connected above the sliding paint spraying board 21, a slider 29 is fixedly connected above the sliding guide rod 28, and a sliding block 29 is fixedly connected below the upper beam 3. The guide chute 30 and the slider 29 are slidably connected to the guide chute 30 , and the cooperation between the slider 29 and the guide chute 30 can achieve a good guiding effect.

[0040] The working principle of the present invention is: turn on the motor 4 during use, the rotation of the motor 4 drives the drive shaft 5 to rotate, the rotation of the drive shaft 5 drives the first bevel gear 6 to rotate, the rotation of the first bevel gear 6 drives the rotation of the second bevel gear 9, and then drives The incomplete bevel gear 10 rotates, and the incomplete bevel gear 10 alternately meshes with the third bevel gear 12 and the fourth bevel gear 13, thereby realizi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com