A steel bar cutting device with automatic loading and adjustable cutting length

A technology of automatic filling and cutting device, applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve the problem of low processing efficiency, difficulty in ensuring the uniformity of cutting length, and the inability of electric saw cutting machines to achieve fixed-length and variable-length cutting, etc. problems, to improve efficiency, ensure uniformity, and achieve the effect of cutting length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

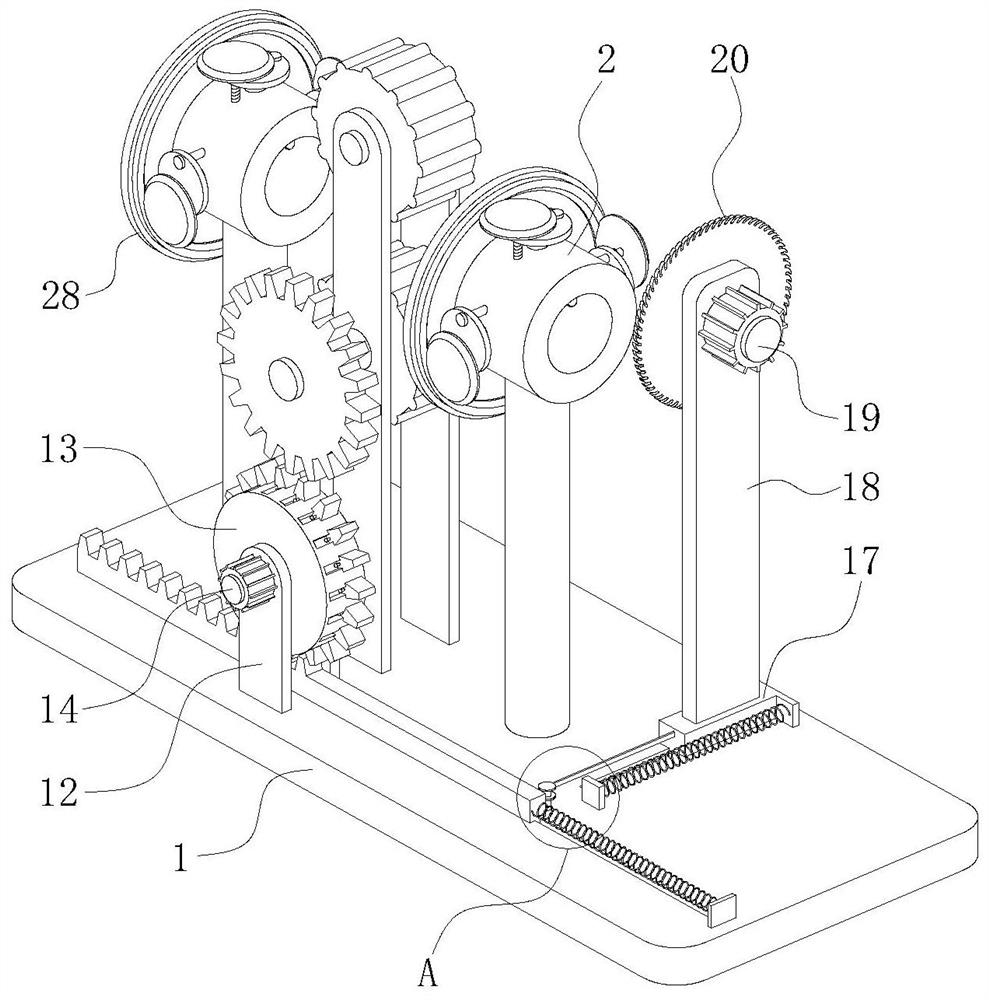

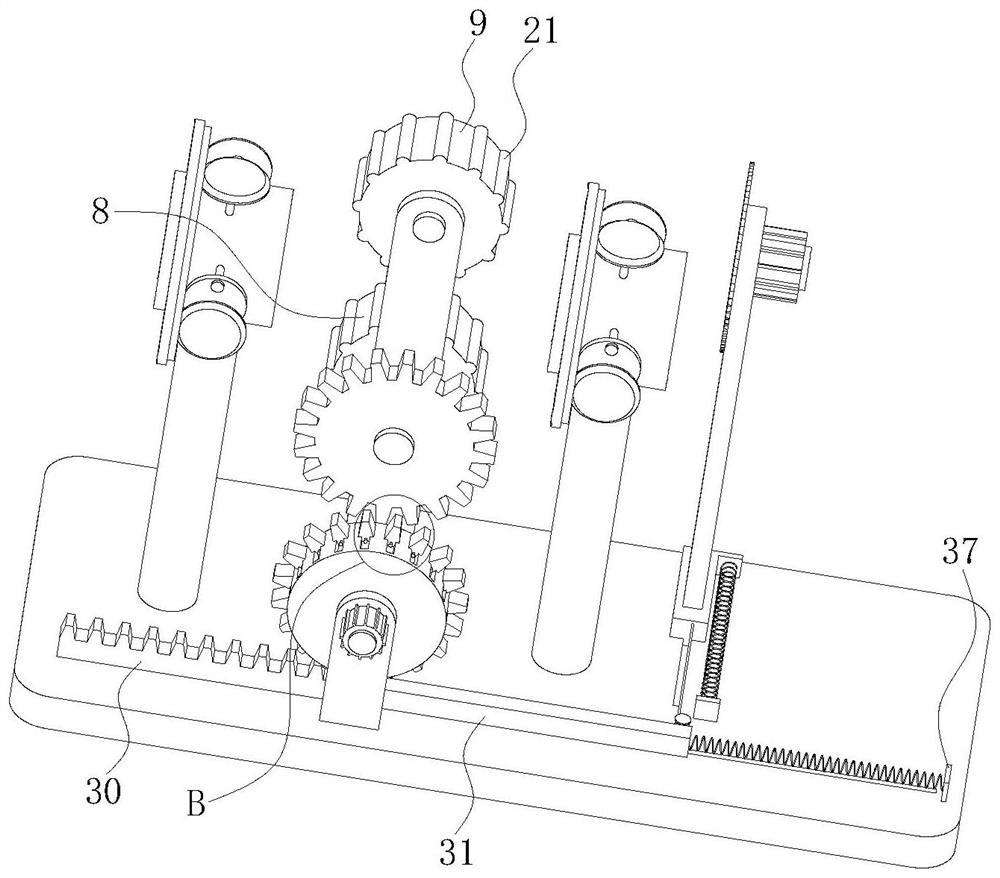

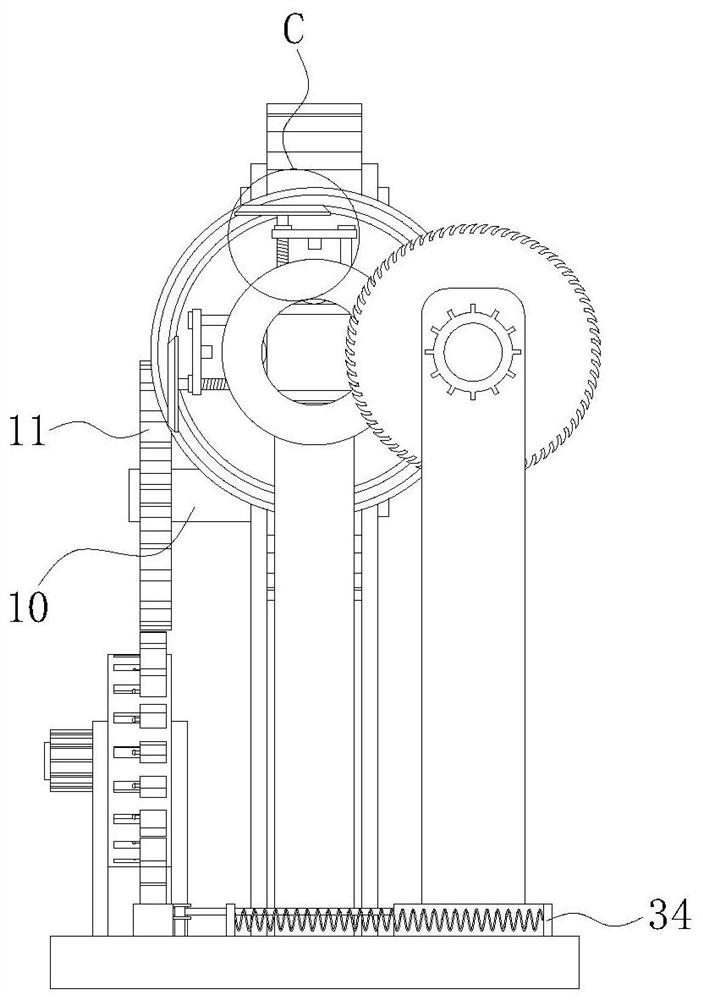

[0030] Such as Figure 1 to Figure 7 As shown, this embodiment provides a steel bar cutting device with automatic loading and adjustable cutting length, including a horizontal bottom plate 1, and the upper surface of the bottom plate 1 is fixedly installed with two horizontal installation cylinders 2 through support columns, and the two installation cylinders 2 The shapes have the same size and the axes coincide with each other. The inner wall of the installation cylinder 2 is provided with at least three sliding slots 3 arranged radially therein. A rolling ball 4 is fitted in the chute 3 and the diameter of the port of the chute 3 is smaller than the diameter of the rolling ball 4 . A support spring 5 is fixedly installed on the end surface of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com