Method for preparing secondary hardening ultrahigh-strength steel through SPS (Spark Plasma Sintering) sintering and deformation

An ultra-high-strength steel and secondary hardening technology, applied in the field of steel material preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

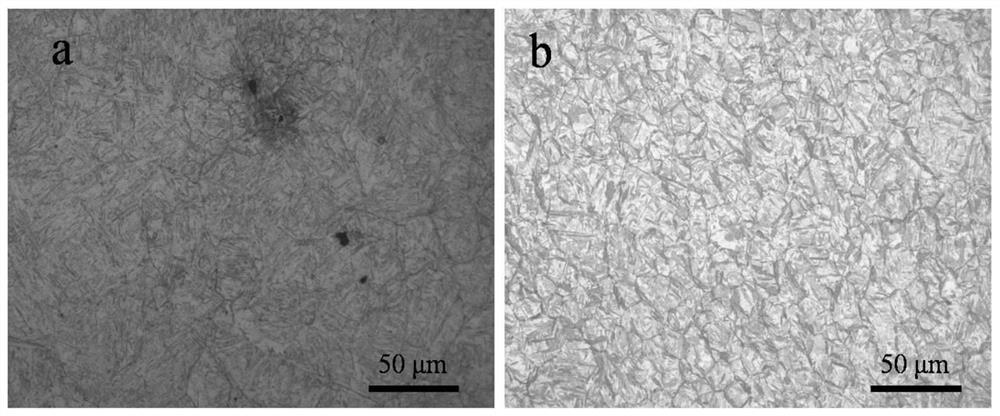

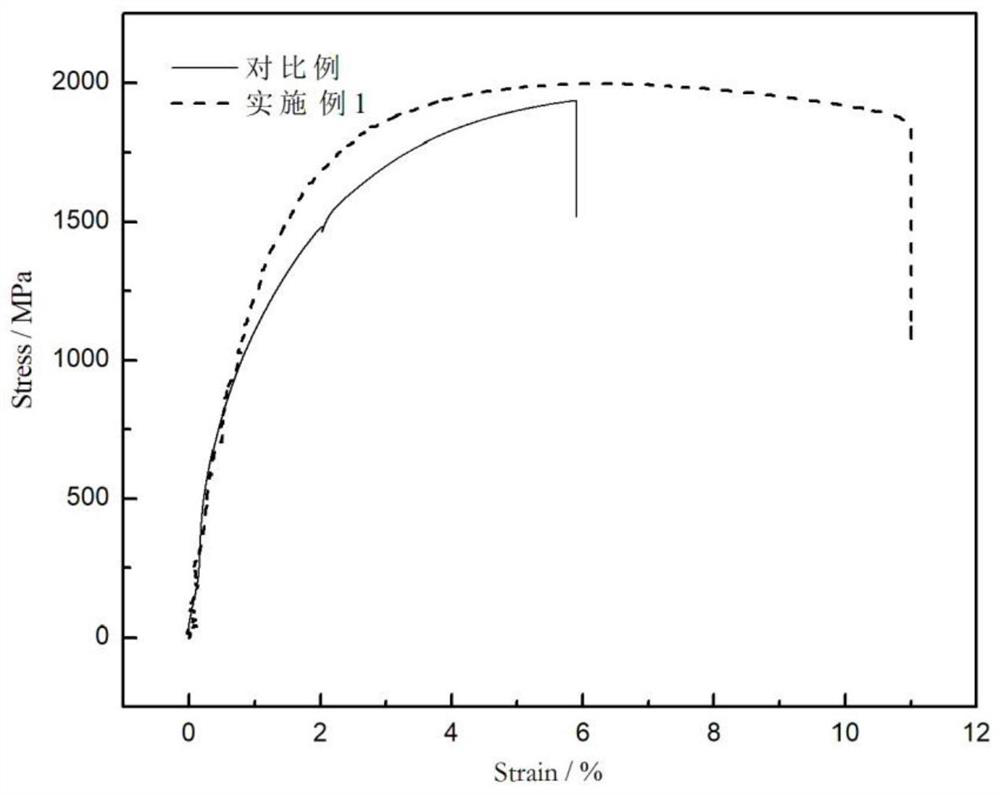

Embodiment 1

[0041] (1) High-pressure and low-temperature preforming: 30g of Ferrium M54 steel powder was placed in a cemented carbide mold with an inner diameter of 20mm, and discharge plasma high-pressure and low-temperature preforming was performed in SPS equipment.

[0042] The specific parameters are: raise the temperature to 500°C at a heating rate of 100°C / min, and keep it at this temperature for 1min, and the axial pressure is 300MPa. Formed compact.

[0043] (2) Low-pressure high-temperature sintering: use 400-mesh SiC sandpaper to grind the preformed compact obtained in step (1) around, remove the graphite paper on the surface of the compact, and then place it in a graphite mold with an inner diameter of 20mm, and carry out in SPS equipment Low pressure high temperature sintering.

[0044] The specific sintering parameters are: raise the temperature at a heating rate of 100°C / min to make the sintering temperature reach 1050°C, and keep it at this temperature for 10 minutes. At t...

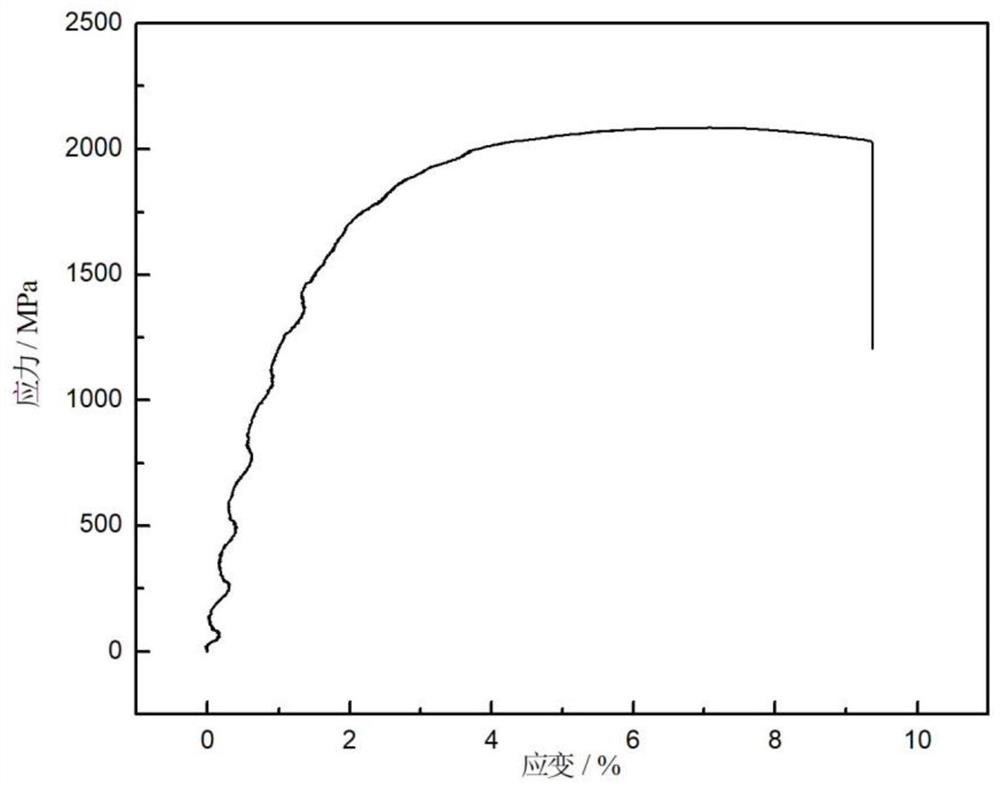

Embodiment 2

[0052] (1) High-pressure and low-temperature preforming: 30g of Ferrium M54 steel powder was placed in a cemented carbide mold with an inner diameter of 20mm, and discharge plasma high-pressure and low-temperature preforming was performed in SPS equipment.

[0053] The specific parameters are: heat up to 600°C at a heating rate of 100°C / min, and hold at this temperature for 2 minutes, and the axial pressure is 500MPa. Formed compact.

[0054] (2) Low-pressure high-temperature sintering: use 400 mesh SiC sandpaper to grind the preformed compact obtained in step (1) around, remove the graphite paper on the surface layer of the compact, and then place it in a graphite mold with an inner diameter of 20mm, and carry out in SPS equipment Low pressure high temperature sintering.

[0055] The specific sintering parameters are: heat up at a heating rate of 100°C / min to make the sintering temperature reach 1100°C, and keep it at this temperature for 15 minutes. At this time, the axial ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com