Leftover material collecting and crushing machine

A technology of pulverizer and side material, which is applied in metal processing, grain processing, etc., to achieve the effect of small space occupation, convenient storage and transfer, and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

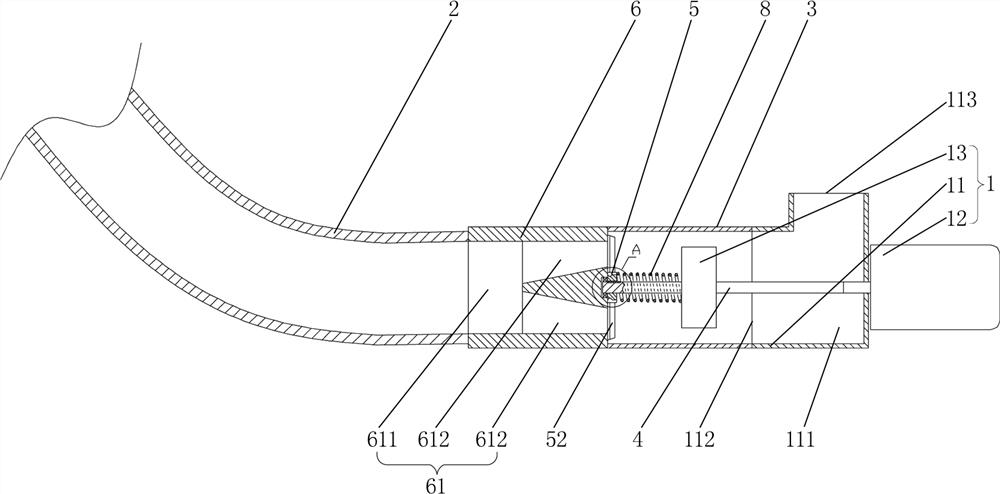

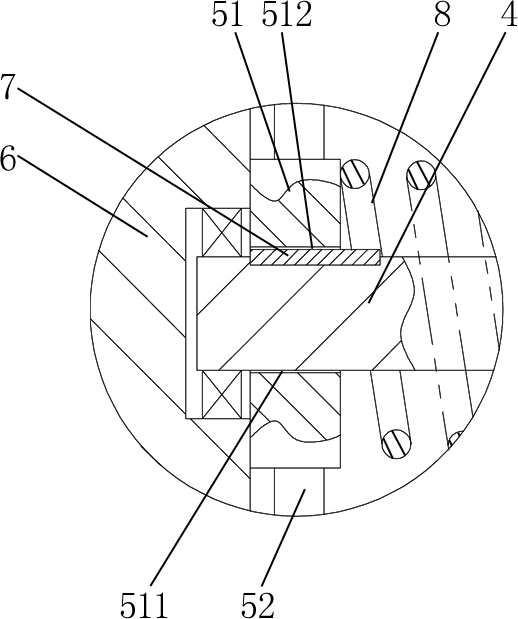

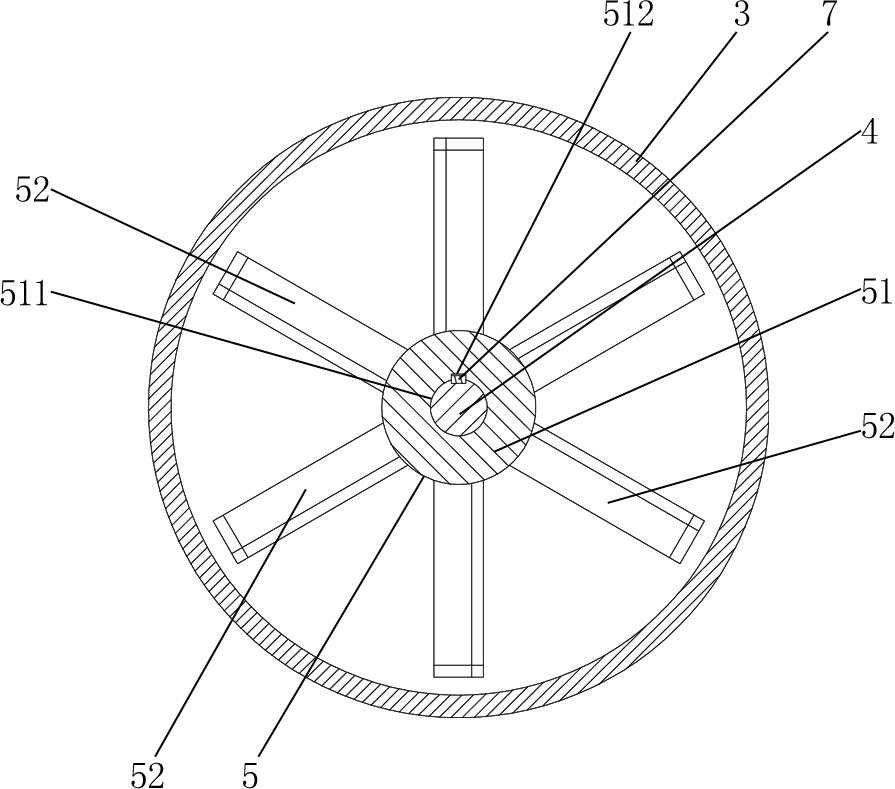

[0018] Such as Figure 1-Figure 3 As shown, this edge material collection pulverizer includes a centrifugal fan 1, an edge material pipeline 2, an air inlet sleeve 3, a main shaft 4, a pulverizer 5, a feed seat 6, a guide key 7 and a compression spring 8; the centrifugal fan 1 includes The fan housing 11, the motor 12 and the impeller 13, the fan housing 11 is provided with an inner chamber 111, the fan housing 11 is provided with an air inlet 112 and an air outlet 113 communicating with the inner chamber 111, and the motor 12 is installed on On the fan housing 11; the rear end of the air inlet sleeve 3 communicates with the air inlet 112, and the rear end of the edge material pipeline 2 communicates with the front end of the air inlet sleeve 3; the main shaft 4 is rotatably installed in the air inlet sleeve 3 and is Going forward and backward, the rear end of the main shaft 4 extends from the air inlet 112 into the inner cavity 111 of the fan housing 11 and is connected with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com