A four-wheel drive robot for iron tower inspection and climbing and its operation method

A four-wheel drive and robot technology, applied in the direction of motor vehicles, transportation and packaging, etc., can solve the problems of consuming the physical strength of maintenance personnel, inconvenient manual climbing, and affecting work efficiency, so as to save time, prevent detachment, and increase safety in use sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

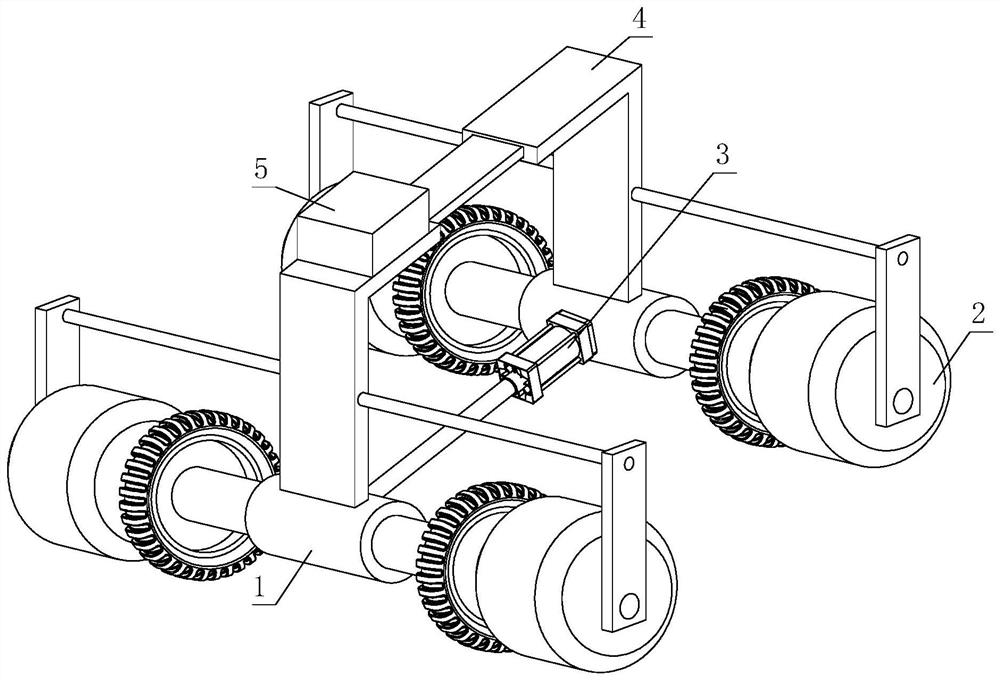

[0033] see figure 1 , a four-wheel drive robot for iron tower maintenance and climbing and an operation method thereof, the four-wheel drive robot for iron tower maintenance and climbing includes a mobile assembly 1, the mobile assembly 1 is driven by a driving device 2, and the mobile assembly 1 is arranged between A movable support 4 is arranged between the lifting and positioning assembly 3 and the moving assembly 1 , and a maintenance device 5 is arranged above the movable support 4 .

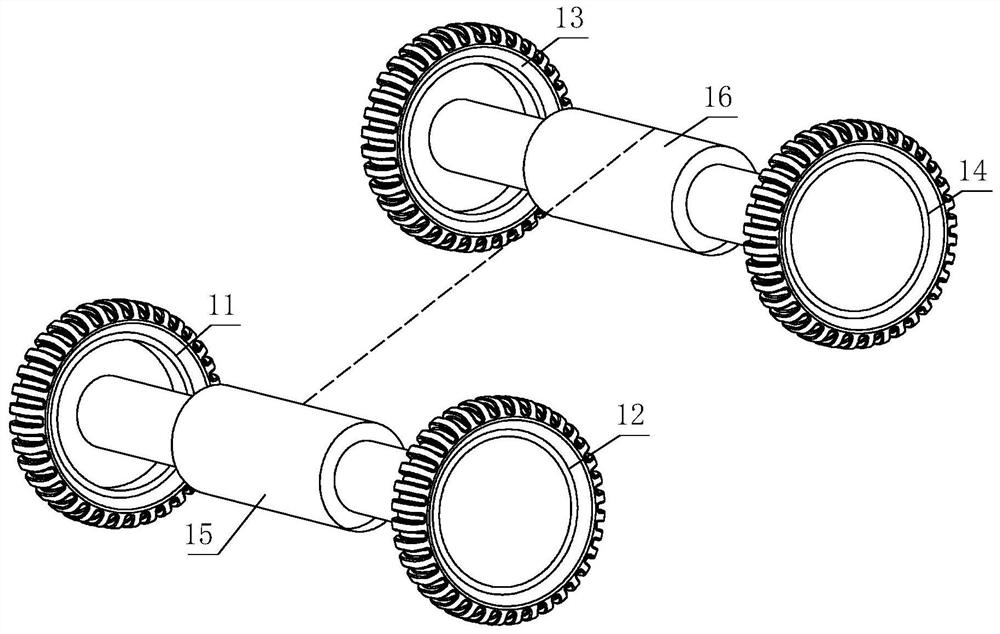

[0034] see figure 2 , the moving assembly 1 comprises a first moving wheel 11, a second moving wheel 12, a third moving wheel 13, a fourth moving wheel 14, a first two-way contraction cylinder 15 and a second two-way contraction cylinder 16, the first movement wheel 11 and the second The first two-way contraction cylinder 15 is connected between the two moving wheels 12, and the output end of the first two-way contraction cylinder 15 one end is connected with the first mobile wheel 11, an...

Embodiment 2

[0044] see Figure 7 , a four-wheel drive robot for iron tower maintenance and climbing and its operation method, comprising a moving assembly 1, the moving assembly 1 is driven by a driving device 2, a lifting and positioning device 6 is arranged between the moving assemblies 1, and the moving assembly 1 includes The first mobile wheel 11, the second mobile wheel 12, the third mobile wheel 13, the fourth mobile wheel 14, the first two-way contraction cylinder 15 and the second two-way contraction cylinder 16, between the first mobile wheel 11 and the second mobile wheel 12 The first two-way shrinkage cylinder 15 is connected between them, the output end of the first two-way shrinkage cylinder 15 is connected with the first moving wheel 11, the output end of the other end of the first two-way shrinkage cylinder 15 is connected with the second moving wheel 12, and the second The output end of two-way contraction cylinder 16 one ends is connected with the 3rd mobile wheel 13, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com