Convenient-to-clean film laminating device for thermal insulation material production

A film coating device and thermal insulation material technology, which is applied in the field of easy-to-clean film coating devices, can solve the problems of inconvenient cleaning of film coating rollers, lack of positioning measures, and poor film covering effects, so as to achieve the goal of convenient cleaning of film film coating rollers Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

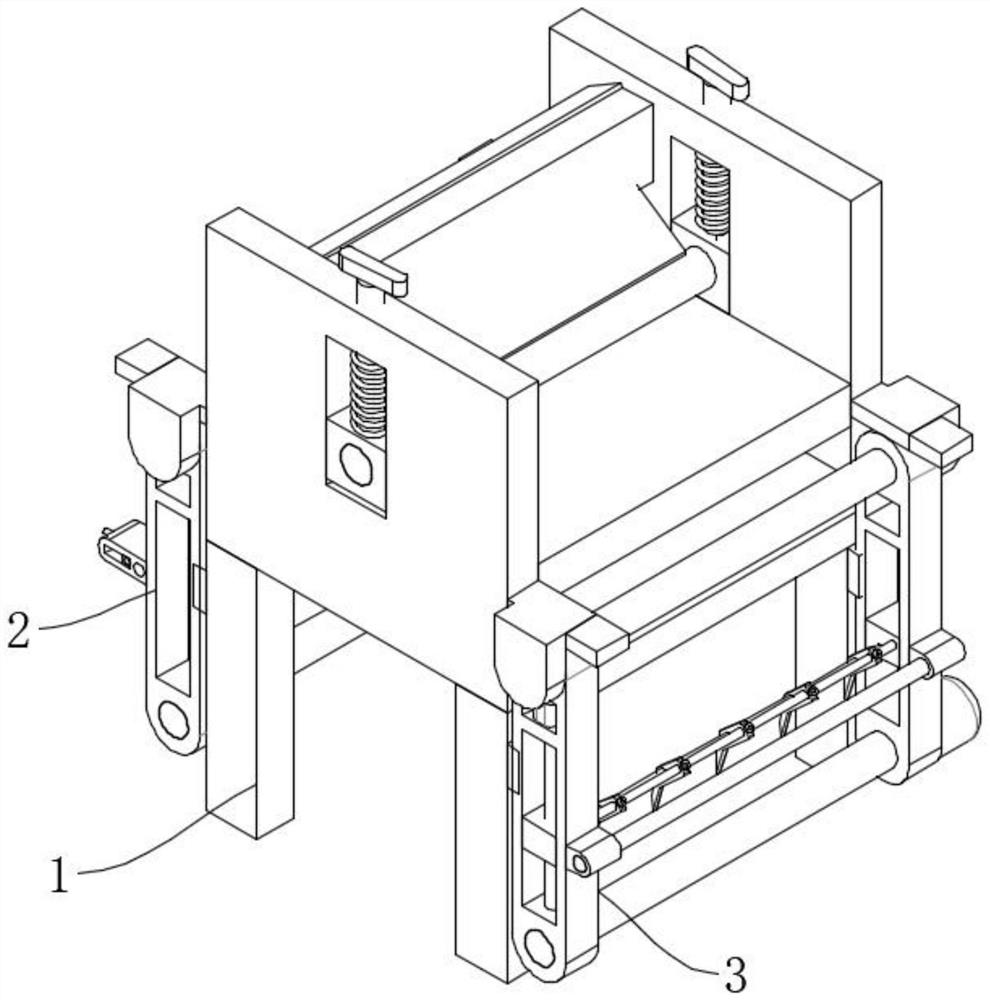

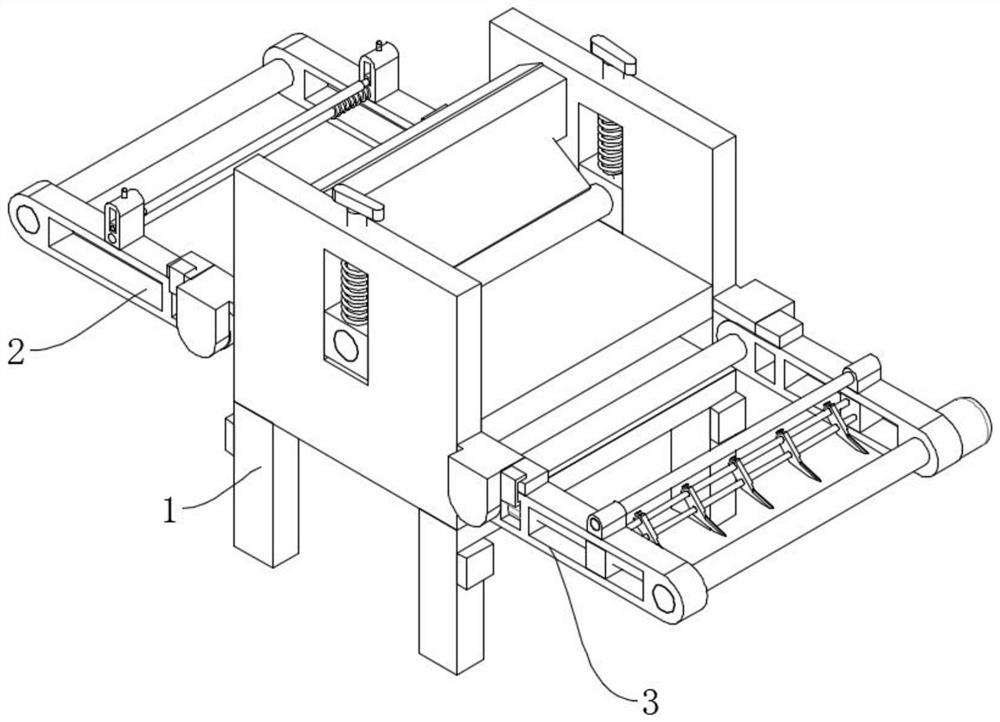

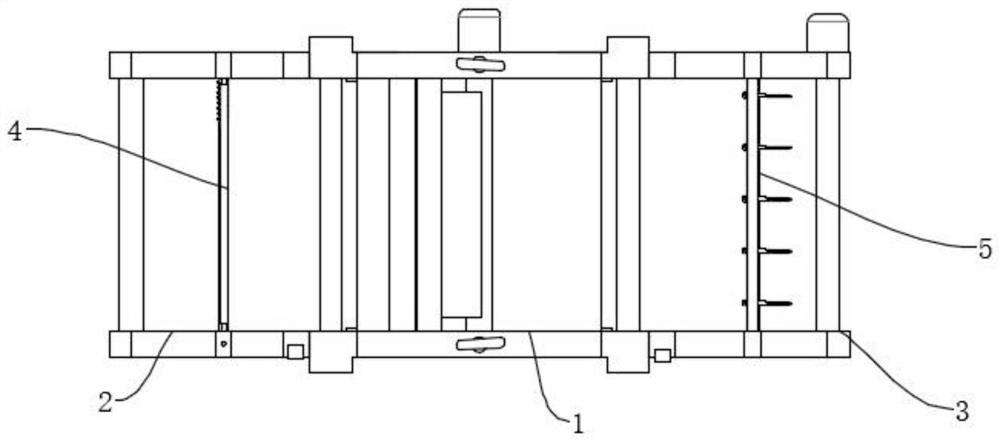

[0036] Such as Figure 1-7 As shown, an easy-to-clean film coating device for the production of thermal insulation materials includes a film covering mechanism 1. The film covering mechanism 1 is mainly composed of a support frame 101, a frame 102, a workbench 103, a film coating roller 106, and a rubber box 110. Composition, the top of the support frame 101 is connected with a frame 102 by bolts, the inside of the frame 102 is connected with a workbench 103 by bolts, a liftable lamination roller 106 is arranged above the workbench 103, and a rubber box 110 is arranged on the top of the lamination roller 106 , and the plastic box 110 is connected to the frame 102 by screws, a foldable feeding mechanism 2 is provided on one side of the frame 102, and a foldable winding mechanism 3 is provided on the other side of the frame 102, so that the setting can be completed after processing Afterwards, the feeding mechanism 2 and the winding mechanism 3 are folded, so that the length of ...

Embodiment 2

[0038] Such as Figure 8 As shown, the difference between Embodiment 2 and Embodiment 1 is that the lifting assembly 109 includes a lifting rod 1091, a connecting plate 10901, and a lifting cylinder 10902. The upper end of the lifting rod 1091 is connected to the connecting plate 10901 by bolts, and the bottom of the connecting plate 10901 is far away from the lifting rod. One end of 1091 is connected with a lifting cylinder 10902 by bolts, and the lifting cylinder 10902 is connected above the frame 102 by screws, and the lower end of the lifting rod 1091 passes through the frame 102 and extends into the inside of the first chute 104, and is fixed on the first slider Above 105, such setting can drive connecting plate 10901 to rise by lifting cylinder 10902, and connecting plate 10901 drives lifting rod 1091 to rise, and lifting rod 1091 drives first slide block 105 to rise, has realized the function that coating roller 106 rises.

[0039] In the above-mentioned structure, when...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com