Medium borosilicate glass composition, medium borosilicate glass and preparation method and application thereof

A borosilicate glass and composition technology, applied in the field of medium borosilicate glass composition, can solve the problems of lines, large corrosion loss, low qualified rate of finished products, etc., achieve bright visual appearance, reduce the difficulty of melting, and prolong the furnace effect of life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

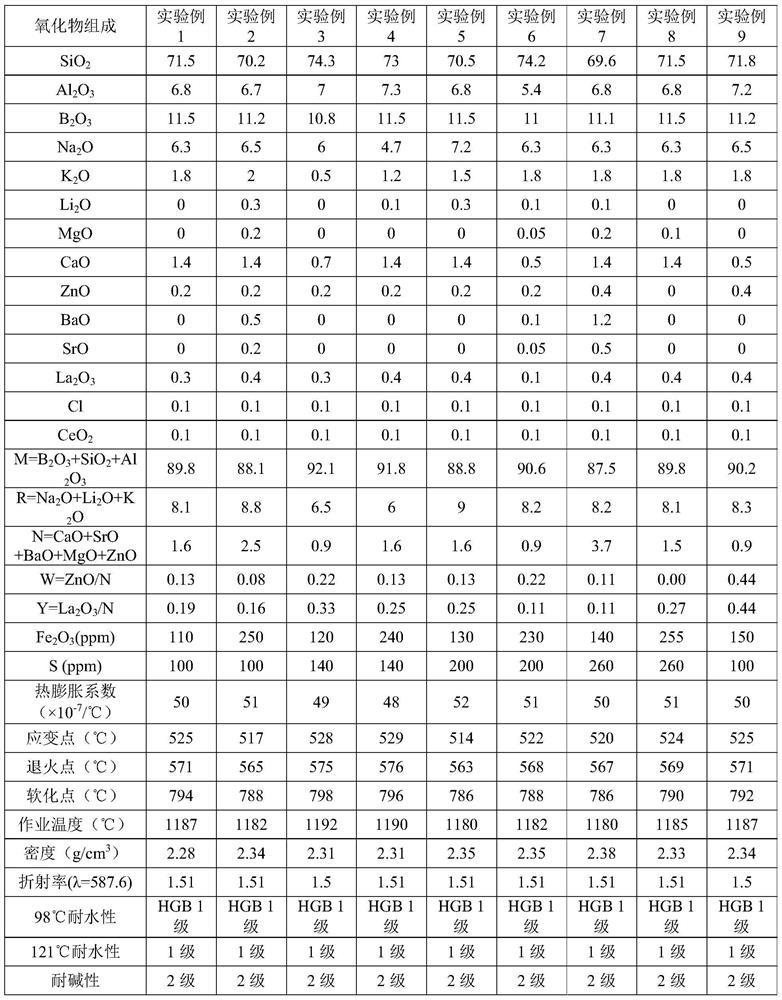

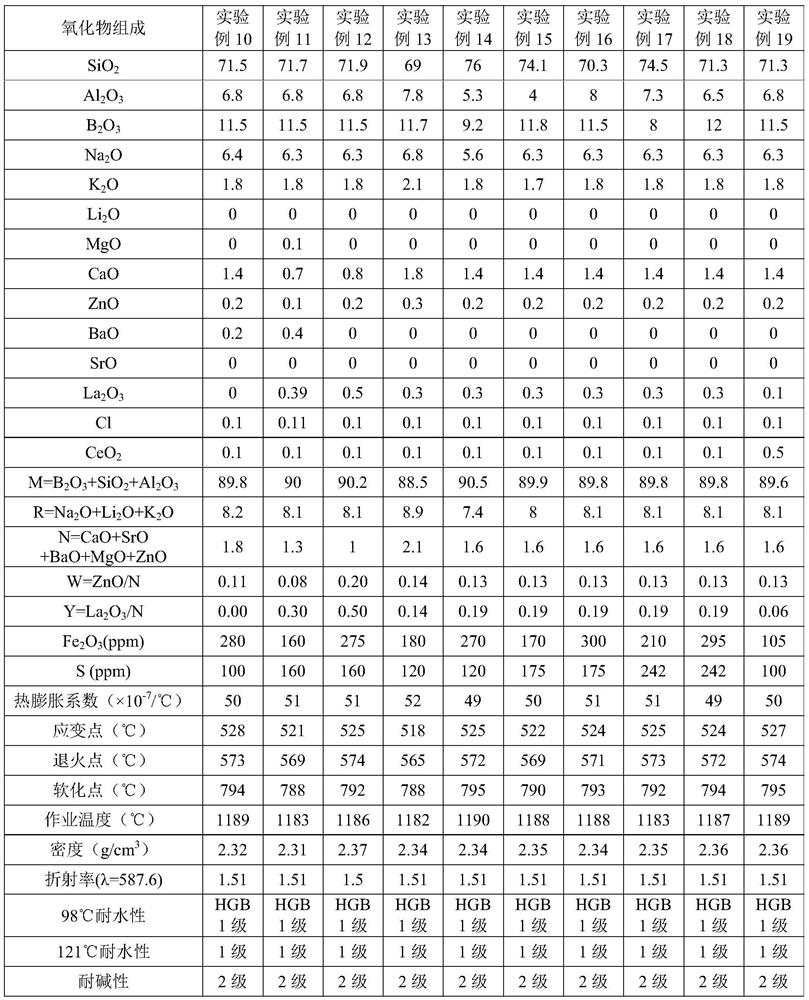

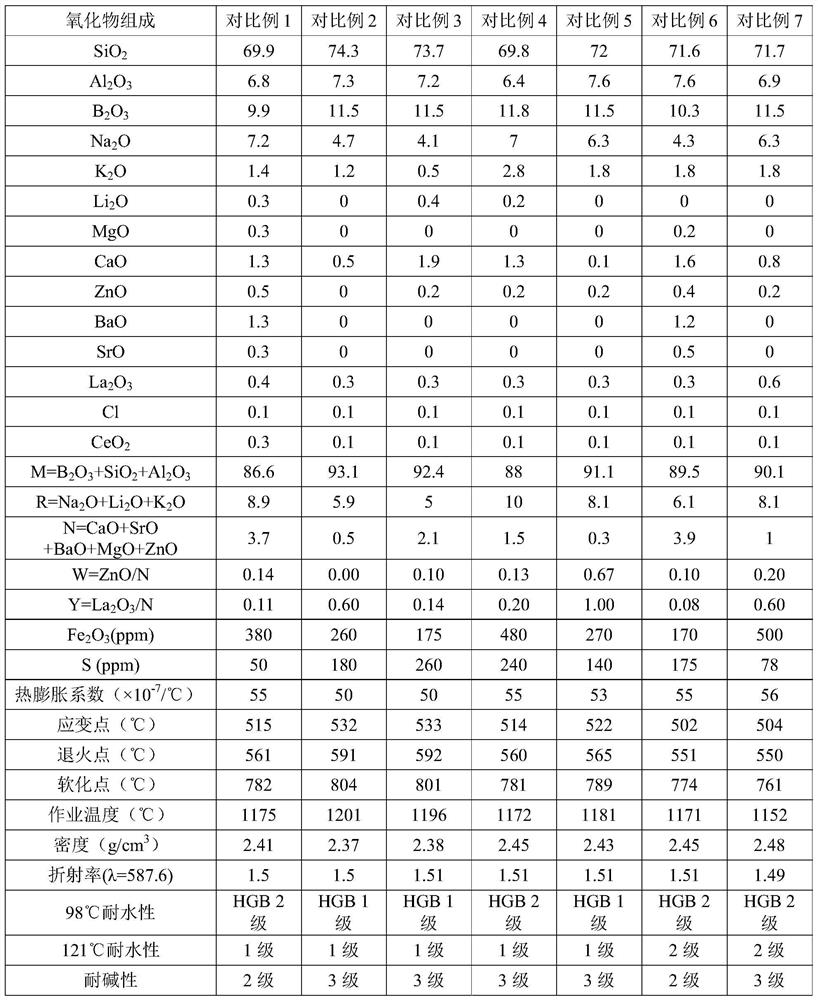

[0048] Specific embodiments of the present disclosure will be described in detail below. It should be understood that each material described here according to the present disclosure can be obtained through market procurement, and if not otherwise specified, the methods used are conventional methods in the art.

[0049]According to the present disclosure, the compositions, contents, sums, and ratios involved in the examples are all mass ratios (%), and the components or measurement units indicated by the units are explained in the table.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| strain point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com