Soft high-stripping hydrolysis-resistant wet leather resin and preparation method thereof

A high-peeling, hydrolysis-resistant technology, applied in textiles and papermaking, can solve the problems of insufficient strength of polyether polyols and complicated processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

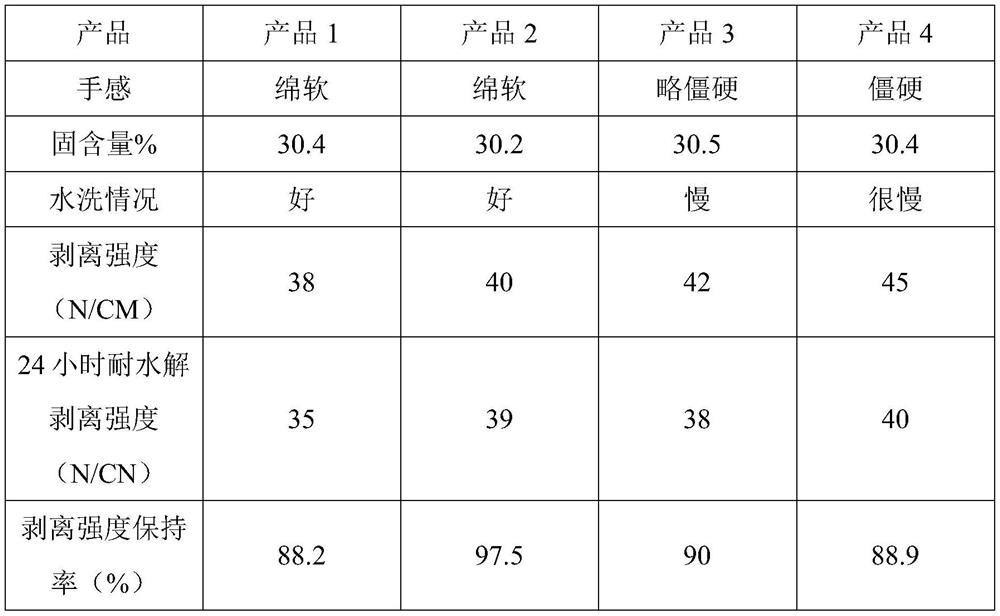

Examples

Embodiment 1

[0030] Weigh the raw materials by weight percentage, put 2070kg mixed polyether polyol, 50kg polyester polyol, 80kg chain extender A and 4000kg DMF into the reaction and stir evenly to obtain the preliminary mixed material;

[0031] Then put in 600kg of MDI and heat it up to 80°C for 60 minutes, then put in the remaining 200kg of MDI, add viscosity, add the remaining 3000kg of DMF in batches, add 5kg of methanol, and finally add 100kg of wet film-forming agent and 100kg of cells Conditioning agent, mixed evenly, cooled and discharged to obtain the final resin product, which was recorded as product 1.

Embodiment 2

[0033] Put 1950kg of mixed polyether polyol, 170kg of polyester polyol, 80kg of chain extender A and 4000kg of DMF into the reaction and stir evenly to obtain a preliminary mixed material;

[0034] Then put in 650kg of MDI and heat it up to 80°C for 80 minutes, then put in the remaining 150kg of MDI, add viscosity, add the remaining 3000kg of DMF in batches, add 5kg of methanol to terminate, and finally add 100kg of wet film-forming agent and 100kg of cell regulator agent, mixed evenly, cooled and discharged to obtain the final resin product, which was recorded as product 2.

Embodiment 3

[0036] Put 1850kg of mixed polyether polyol, 270kg of polyester polyol, 80kg of chain extender A and 4000kg of DMF into the reaction and stir evenly to obtain a preliminary mixed material;

[0037] Then put in 700kg of MDI and heat it up to 70°C for 90 minutes, then put in the remaining 100kg of MDI, add viscosity, add the remaining 3000kg of DMF in batches, add 5kg of methanol to terminate, and finally add 100kg of wet film-forming agent and 100kg of cell regulator agent, mixed evenly, cooled and discharged to obtain the final resin product, which was recorded as product 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com