Waste heat boiler

A technology of waste heat boilers and tube boxes, which is applied in the direction of steam boilers, steam boiler accessories, steam boiler components, etc., and can solve the problems of difficult production and easy damage of heat exchange tubes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing, the present invention is further described;

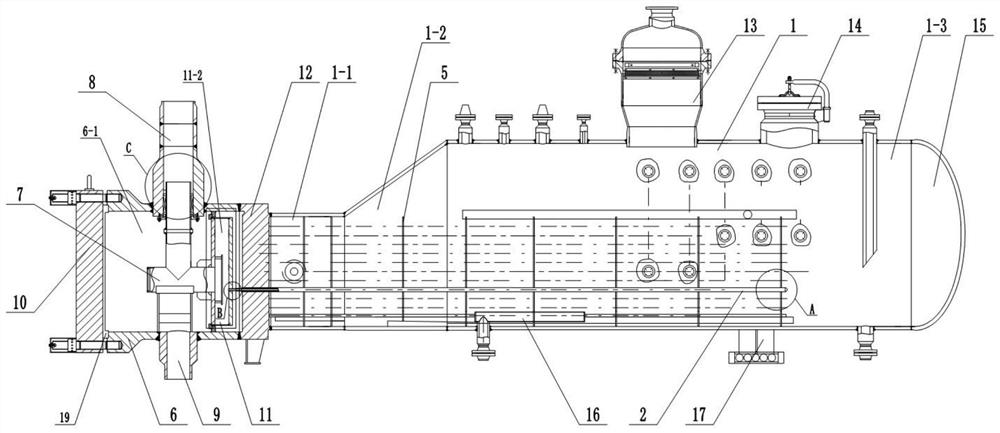

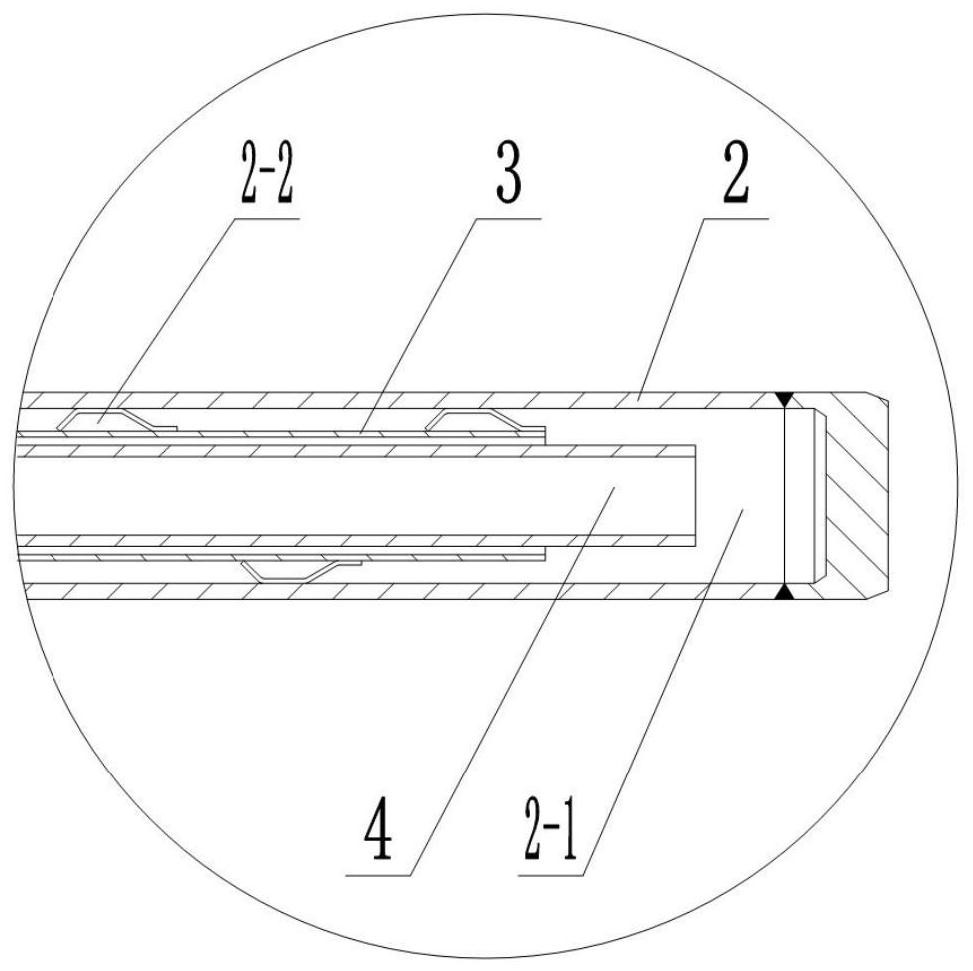

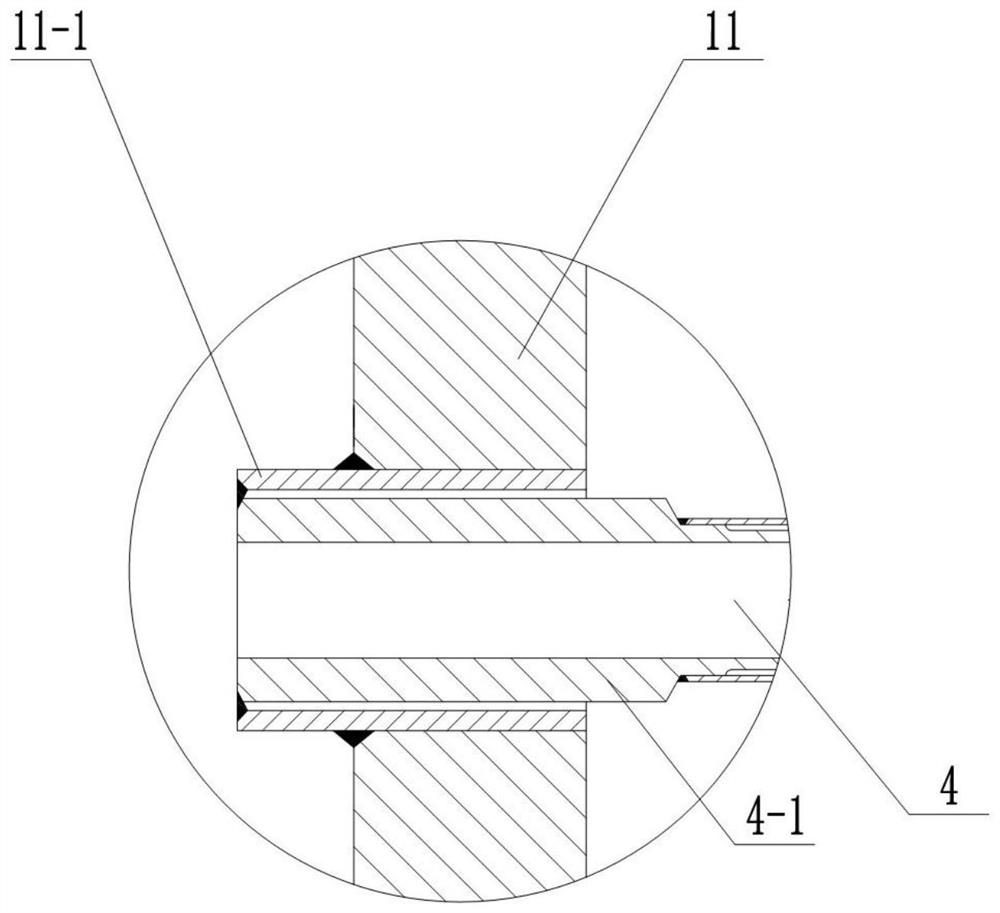

[0019] Please refer to Figure 1-4 , a waste heat boiler, comprising a shell 1, a tube box 6, a tube box inner part 7 arranged in the tube box 6, a flat cover 10 arranged at the front end of the tube box 6, a sealing head 15 arranged at the rear end of the casing 1, Manhole 14, support chassis 17, the upper interface of the pipe box inner part 7 is provided with an air intake pipe 8, the lower interface of the pipe box inner part 7 is provided with an exhaust pipe 9, and the housing 1 is formed by the front cylinder 1-1. The special-shaped middle cylinder 1-2 and the rear cylinder 1-3 are fixedly connected in sequence. A tube plate 12 is arranged between the front cylinder 1 and the tube box 6. The tube plate 12 is near A gas distribution cylinder 11 is provided, and the gas distribution cylinder 11 is arranged at the rear end of the inner part 7 of the pipe box, and a plurali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com