Metal/ceramic wave-absorbing composite material and preparation method thereof

A composite material and ceramic powder technology, applied in shielding materials, chemical instruments and methods, and other chemical processes, can solve the problems of complex preparation process, high preparation cost, and difficulty in the preparation of interference-type ceramic wave-absorbing materials, and achieve The effect of reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] A method for preparing a metal / ceramic wave-absorbing composite material, comprising the steps of:

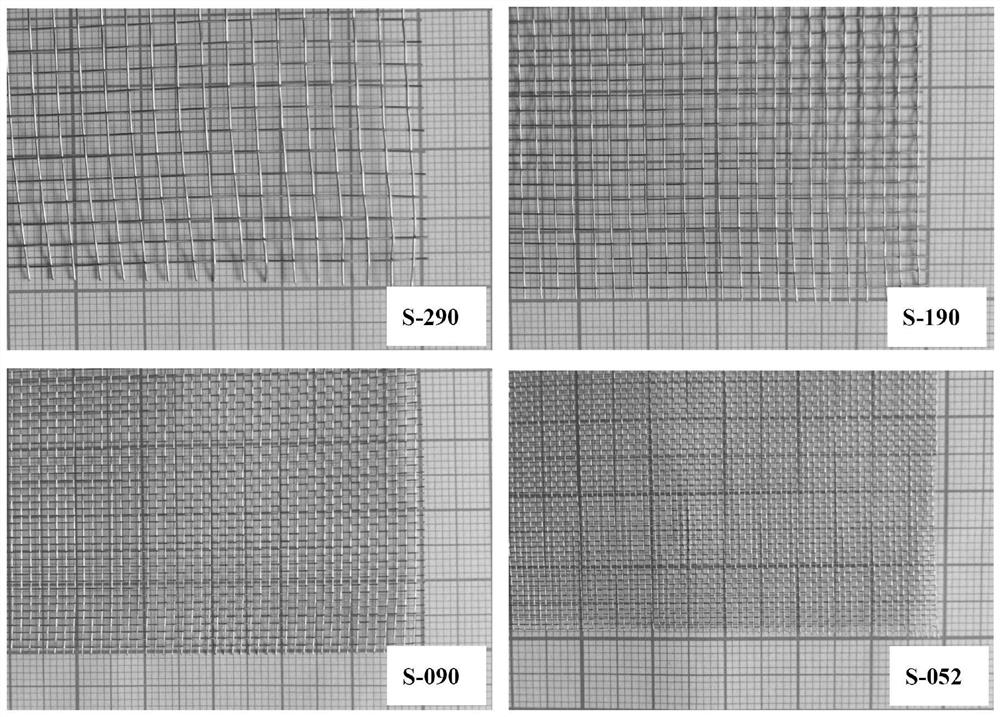

[0044] (1) will figure 2 Cut the metal mesh numbered S-190 into a size of 160mm×160mm, and set aside;

[0045] (2) Prepare quartz sand, albite, potassium feldspar, borax, talcum powder, and zinc oxide in a weight ratio of 50:2:2:16:8:3, and then add calcium carbonate, the weight percentage of calcium carbonate 3%;

[0046] (3) Utilize a ball mill to carry out ball milling to the raw materials prepared in step (2), to obtain a mixed dry material with a particle size less than 5 microns;

[0047] (4) Add water to the mixed dry material of step (3), continue ball milling to obtain mixed wet material, the weight percentage of water in the mixed wet material is 10%;

[0048] (5) Pour the mixed wet material in step (4) into a metal mold, and embed the metal mesh numbered S-190 cut in step (1) in the mixed wet material;

[0049] (6) molding the mixed wet material in the me...

Embodiment 2

[0054] A method for preparing a metal / ceramic wave-absorbing composite material, comprising the steps of:

[0055] (1) will figure 2 Cut the metal mesh numbered S-090 into a size of 160mm×160mm, and set aside;

[0056] (2) Prepare quartz sand, albite, potassium feldspar, borax, talcum powder, and zinc oxide in a weight ratio of 70:4:4:24:12:5, and then add calcium carbonate, the weight percentage of calcium carbonate 4%;

[0057] (3) Utilize a ball mill to carry out ball milling to the raw materials prepared in step (2), to obtain a mixed dry material with a particle size less than 5 microns;

[0058] (4) Add water to the mixed dry material of step (3), continue ball milling to obtain mixed wet material, the weight percentage of water in the mixed wet material is 8%;

[0059] (5) Pour the mixed wet material in step (4) into a metal mold, and embed the metal mesh numbered S-090 cut in step (1) in the mixed wet material;

[0060] (6) molding the mixed wet material in the me...

Embodiment 3

[0065] A method for preparing a metal / ceramic wave-absorbing composite material, comprising the steps of:

[0066] (1) will figure 2 The metal mesh numbered S-052 is cut into a size of 160mm×160mm for use;

[0067] (2) Prepare quartz sand, albite, potassium feldspar, borax, talcum powder, and zinc oxide in a weight ratio of 60:3:3:20:10:4, and then add calcium carbonate, the weight percentage of calcium carbonate 5%;

[0068] (3) Utilize a ball mill to carry out ball milling to the raw materials prepared in step (2), to obtain a mixed dry material with a particle size less than 5 microns;

[0069] (4) Add water to the mixed dry material of step (3), continue ball milling to obtain mixed wet material, the weight percentage of water in the mixed wet material is 6%;

[0070] (5) Pour the mixed wet material in step (4) into a metal mold, and embed the metal mesh numbered S-052 cut in step (1) in the mixed wet material;

[0071] (6) Molding the mixed wet material in the metal ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com