A non-gas dry quenching method

A dry coke quenching, non-gas technology, applied in coke ovens, coke cooling, energy input, etc., can solve the problems of combustible gas safety hazards, malodorous gas uncontrollable, system reliability reduction, etc. less, reduce occupational risk and cost of operation, and have high energy-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

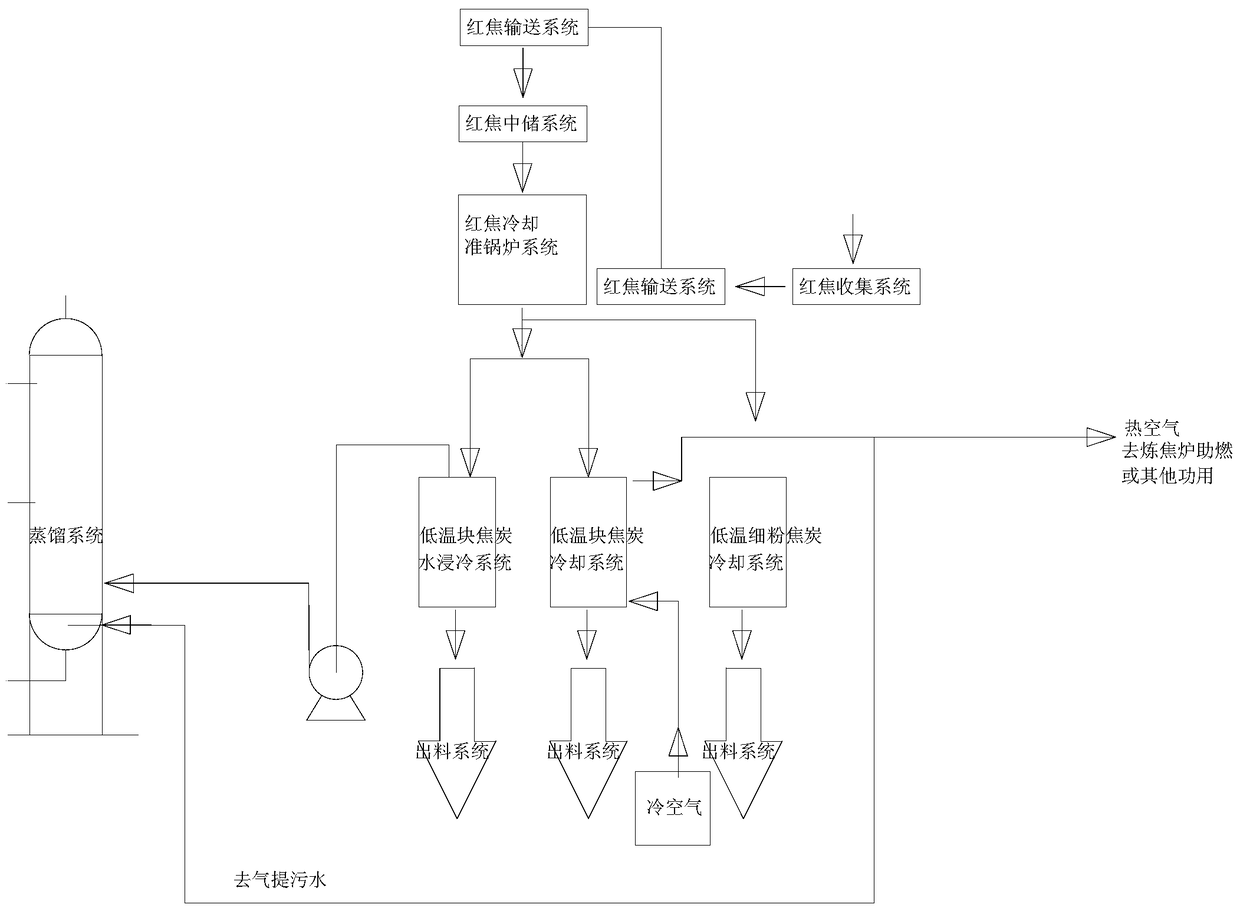

[0017] Such as figure 1 As shown, the coke at 1050-950°C coming out of the coke oven is usually called red coke. The red coke enters the red coke collection system, and after being collected by the red coke collection system, it is sealed and isolated from the air, and the red coke is introduced into the red coke by the red coke collection system. In the red coke intermediate storage system, if necessary, a red coke conveying system can be set between the red coke collection system and the red coke intermediate storage system, and the red coke conveying system will send the red coke into the red coke intermediate storage system. The medium storage system for red coke can use a storage tank capable of continuous feeding.

[0018] The red coke is temporarily stored in the red coke intermediate storage system. The continuous feeding device in the red coke intermediate storage system controls the red coke to be fed into the red coke cooling quasi-boiler system in a small, uniform ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com