Flat plate type hybrid permanent magnet linear motor

A hybrid permanent magnet and linear motor technology, applied in magnetic circuits, electrical components, electromechanical devices, etc., can solve problems such as low calorific value and increased cost of logistics sorting platforms, and achieve cost reduction, small positioning force, and high utilization rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

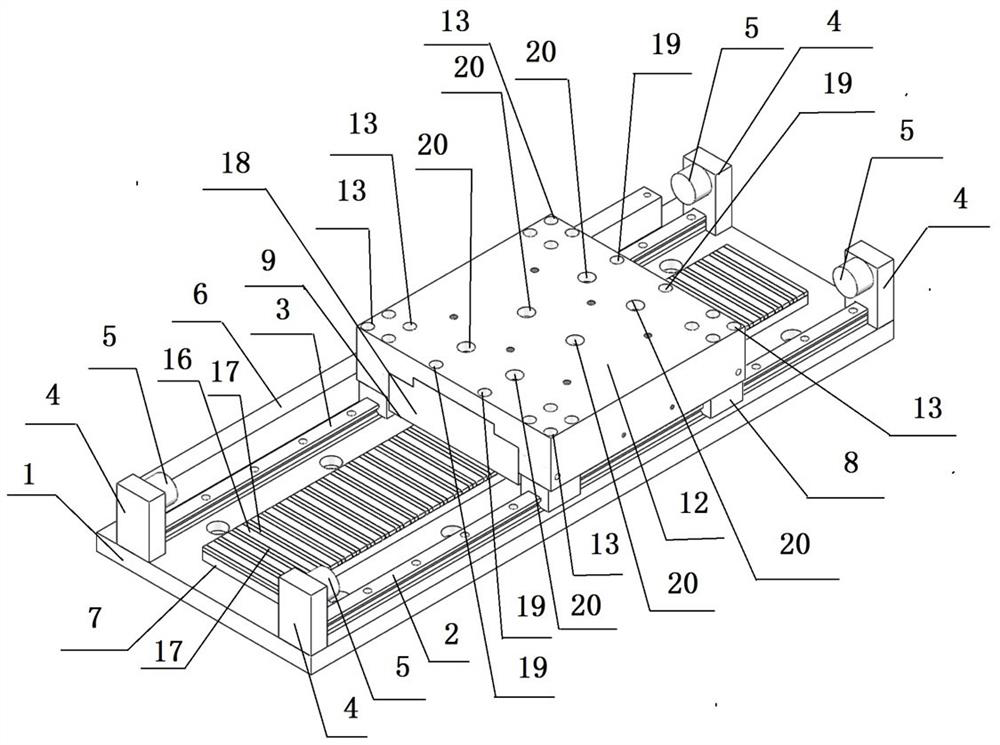

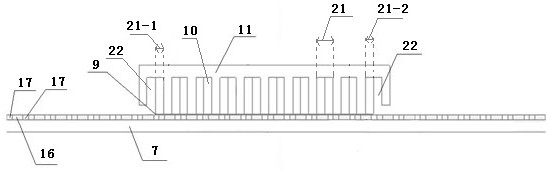

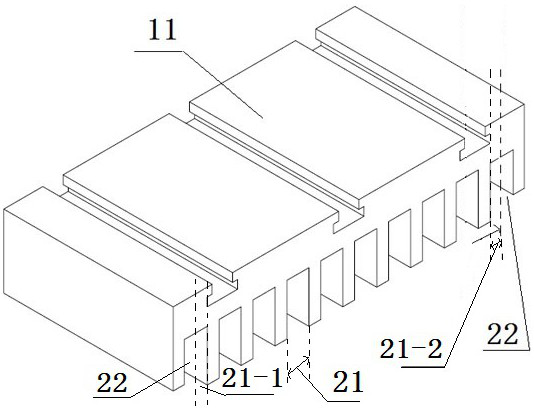

[0029]EXAMPLES: One flat-type mixed permanent magnet linear motor, including the bottom plate 1, the motor primary, and the motor secondary, the front side of the upper surface of the bottom plate 1 is provided with a first rail 2, and the rear side is provided with a second rail 3, the first guide 2 is provided with a limit block 4, respectively, each of which is provided with the left and right sides of the second rail 3, and each limit block 4 is provided with a buffer pad 5, a second rail on the first rail 2 or the second rail 3. The outer side of the 3 is provided with a magnetic gate 6, and a secondary back plate 7 is provided on the bottom plate 1 between the first guide rail 2 and the second rail 3, and the secondary back plate 7 is provided on the secondary back plate 7, and the first rail 2 is provided. The second rail 3 is respectively provided with two sliding blocks 8 which can freely slide on the first guide rail 2 and the second rail 3, together with a motor primary, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com