Compensation method for installation error of Hall sensor in permanent magnet synchronous motor

A technology of permanent magnet synchronous motor and hall sensor, which is applied in the estimation/correction of motor parameters, electronic commutator, etc., and can solve the initial installation position deviation of permanent magnet synchronous motor and the installation error of hall sensor of permanent magnet synchronous motor and other problems, to achieve the effect of reducing position deviation, good sine degree and improving sine degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings.

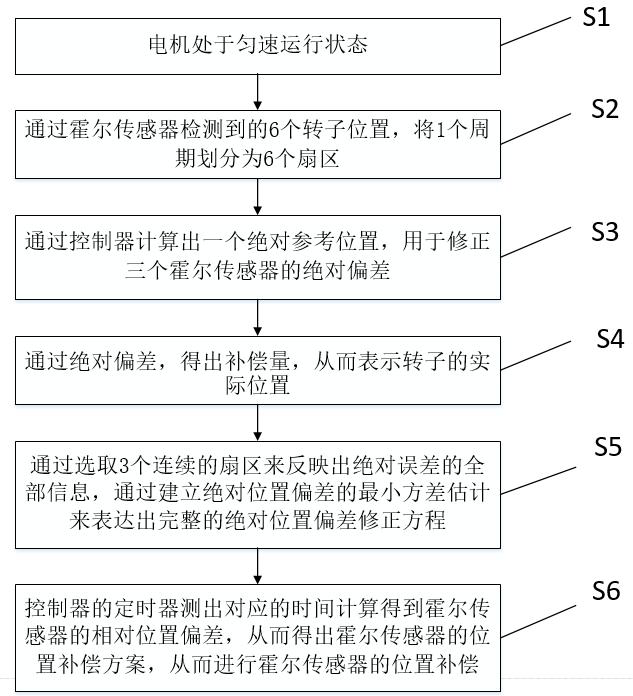

[0036] The invention provides a method for compensating the installation error of the hall sensor of the permanent magnet synchronous motor based on the least square method, such as figure 1 As shown, the specific method includes the following steps:

[0037] Step S1: The permanent magnet synchronous motor first adopts a constant voltage ratio control method to make the motor run at a constant speed.

[0038] Step S2: Divide one period into six sectors through the six rotor positions detected by the Hall sensor.

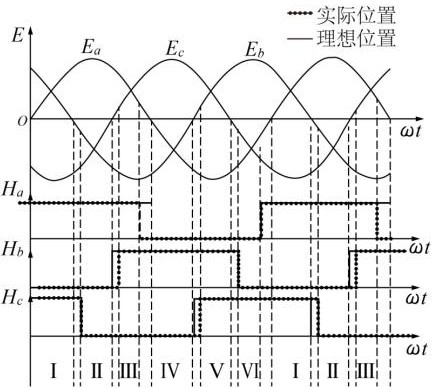

[0039] Such as figure 2 As shown, when the motor is running at a constant speed, a period is divided into 6 sectors through the 6 rotor positions detected by the Hall sensor, and the controller can detect the electrical angle corresponding to each sector. The specific calculation formula for:

[0040]

[0041] Among...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com