Universal drill bit for steel part machining

A general-purpose drill bit and drill bit technology, which is applied in metal processing equipment, drill repairing, drilling tool accessories, etc., can solve the problems of insufficient, easy-to-break edge machining accuracy, etc., and achieve the effects of reducing wear, avoiding edge chipping, and ensuring central strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

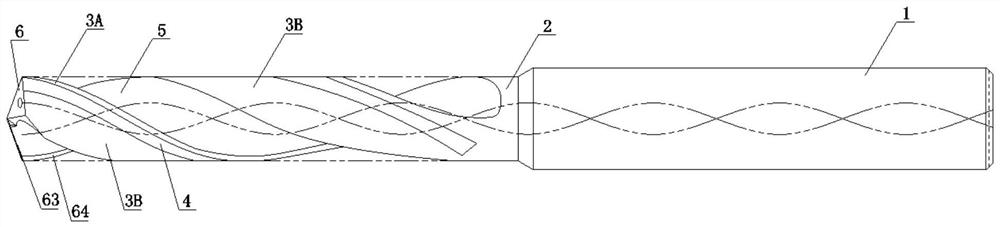

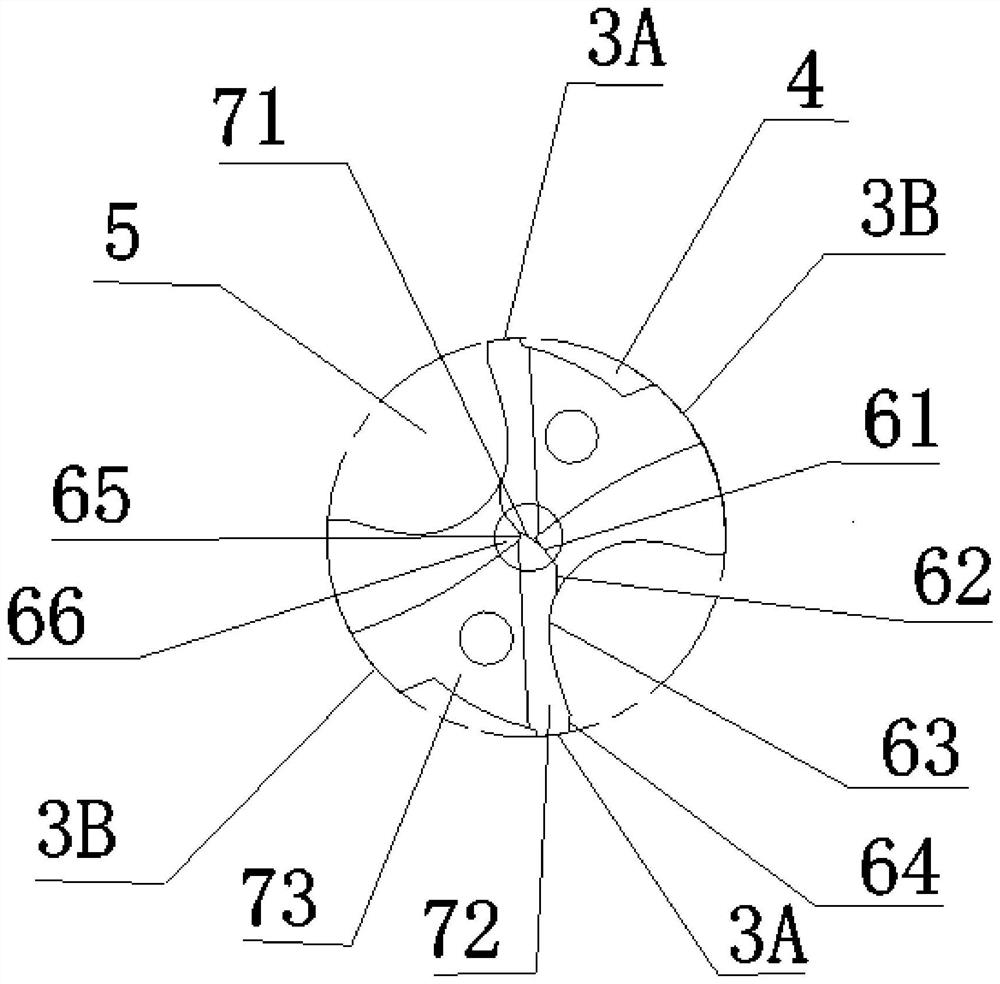

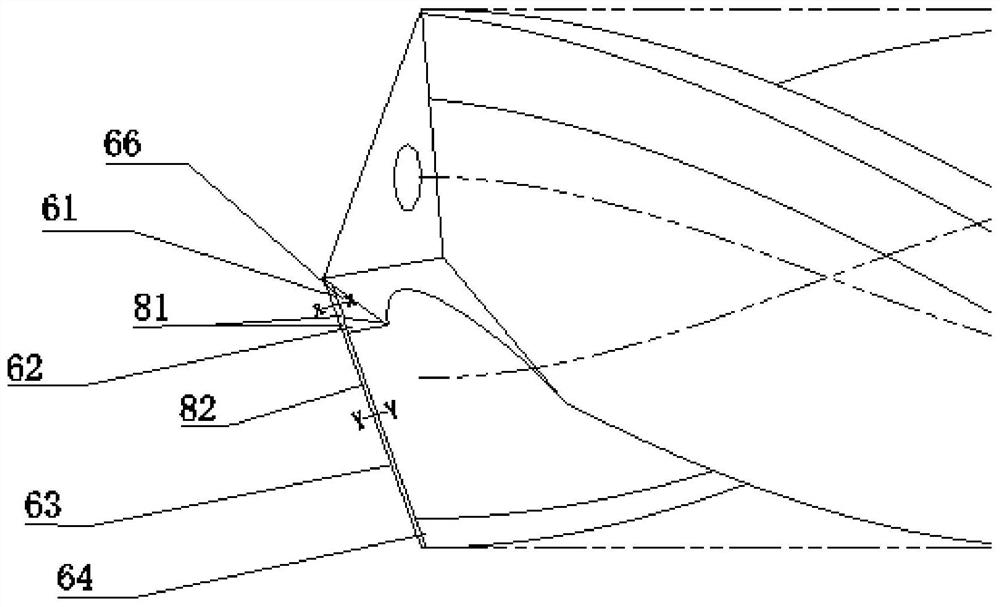

[0021] figure 1 It is a schematic diagram of the structure of a general drill bit used for processing steel parts in the embodiment of the present invention.

[0022] See figure 1 The universal drill bit used for steel parts processing according to the embodiment of the present invention includes a drill bit body, and the drill bit body includes a shank 1, a blade portion 2 and a drill tip 6, and the blade portion 2 is provided with a taper to prevent the concentration of cutting amount and reduce cutting resistance; the blade portion 2 has two helical grooves 5, the two helical grooves 5 are arranged symmetrically, the helix angle θ of the helical grooves 5 is 20° to 30°, and the core thickness of the helical grooves 5 is The diameter of the drill body is 21% to 28%, and the large-depth spiral groove 5 ensures the effect of chip removal.

[0023] Sp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Helix angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com