Manipulator for industrial workshop automatic production line

An automated production line and manipulator technology, applied in the direction of manipulators, program-controlled manipulators, manufacturing tools, etc., can solve the problems of falling objects, poor manipulator adaptability, low stability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

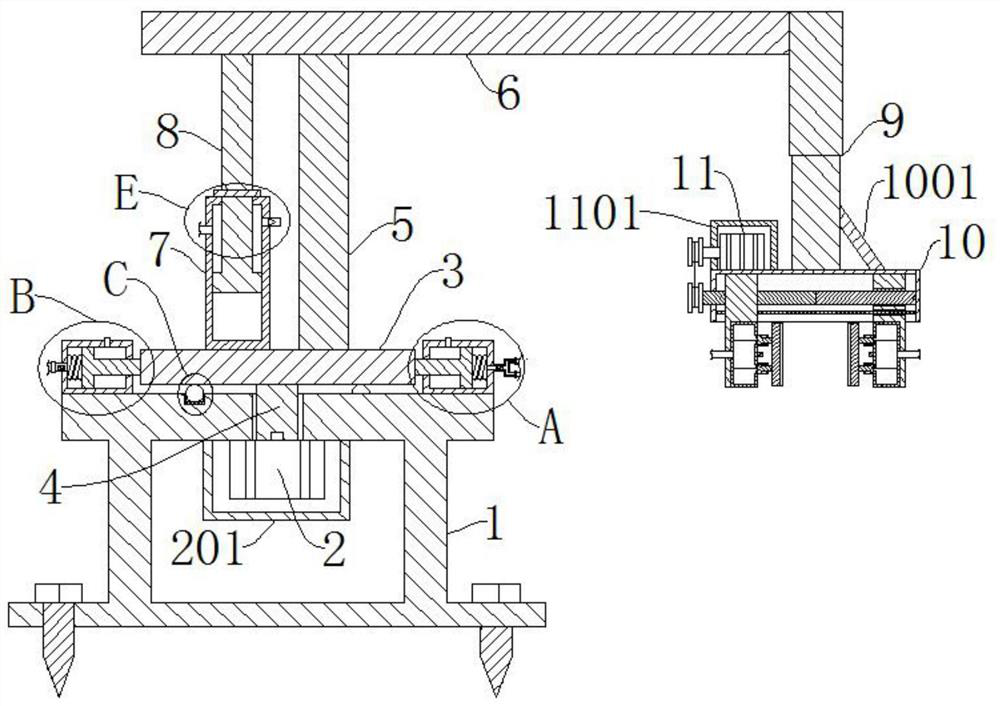

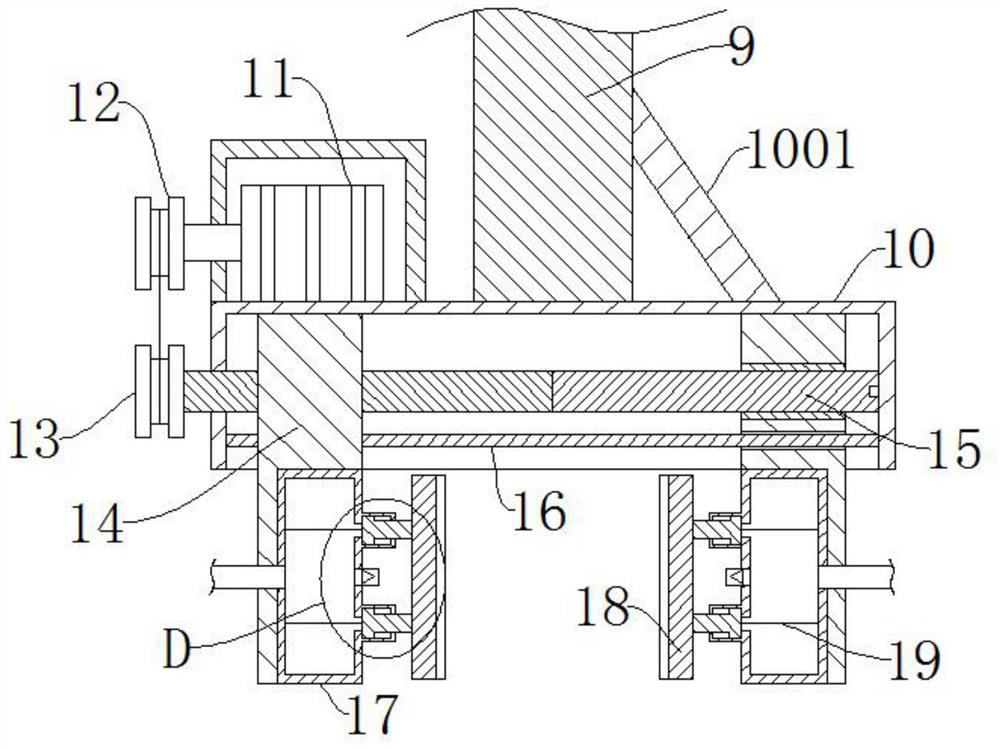

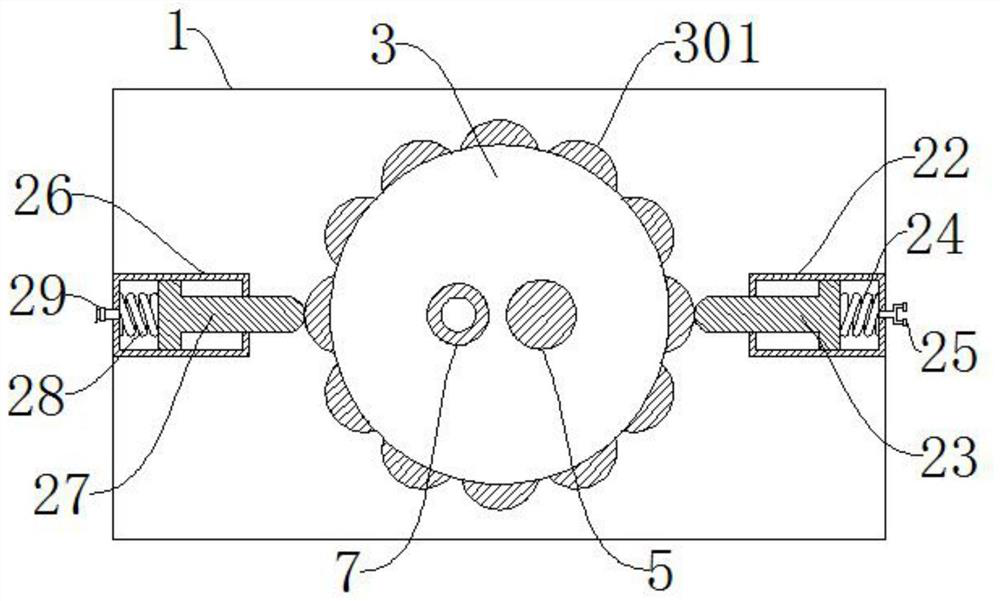

[0031] refer to Figure 1-8 , a manipulator for an automated production line in an industrial workshop, comprising a base 1 and a first motor 2, the base 1 and the first motor 2 are fixedly connected, the output end of the first motor 2 is fixedly connected to a rotating shaft 4, and the rotating shaft 4 is far away from the first motor. One end of a motor 2 runs through the base 1, and is fixedly connected with a rotating plate 3, and the rotating plate 3 is fixedly connected with a column 5, and the upper end of the column 5 is fixedly connected with a fixed rod 6, and the end of the fixed rod 6 away from the column 5 is fixedly connected with a telescopic The lower end of the rod 9 telescopic rod 9 is fixedly connected with a fixed box 10, and two symmetrical bearing blocks 14 are slidably connected in the fixed box 10, and the forward and reverse screw mandrel 15 is connected with the rotation in the fixed box 10, and the forward and reverse screw mandrel 15 is connected wi...

Embodiment 2

[0034] refer to Figure 1-8 , a manipulator for an automated production line in an industrial workshop, which is basically the same as in Embodiment 1, and furthermore: one side of the upper end of the rotating plate 3 is fixedly connected to the cylinder 7, and one side of the upper end of the cylinder 7 is provided with an air inlet, and the cylinder 7 is away from One end of the air inlet is provided with a safety valve, the cylinder 7 is sealed and slidably connected with a moving column 8, the upper end of the moving column 8 is fixedly connected with the fixed rod 6, and the opening of the cylinder 7 and the moving column 8 are sealed by a seal 701 , the upper end of the base 1 away from the second cylinder 22 is fixedly connected with the third cylinder 26, the third cylinder 26 is slidingly connected with the second piston 27, the second piston 27 is attached to the arc-shaped protrusion 301, the third cylinder 26 is fixedly connected with an air outlet pipe 29 at one ...

Embodiment 3

[0036] refer to Figure 1-8 , a manipulator for an automated production line in an industrial workshop, which is basically the same as in Embodiment 1, furthermore: grooves are provided on both sides of the upper end of the base 1, and balls 101 are rollingly connected in the grooves, and the balls 101 are connected to the bottom of the rotating plate 3 Stick to each other, improve the stability of the rotating plate 3, and prevent the rotating plate 3 from tilting due to the overweight of the object to be moved, which will affect the work progress.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com