Waterproof and antistatic treatment method for PCB of sensing type switch

A technology of PCB board and processing method, which is applied in the field of waterproof and antistatic manufacturing and processing, can solve the problems of high cost, accumulated film, and difficulty in meeting environmental protection requirements, and achieve the effect of reducing processing cost and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

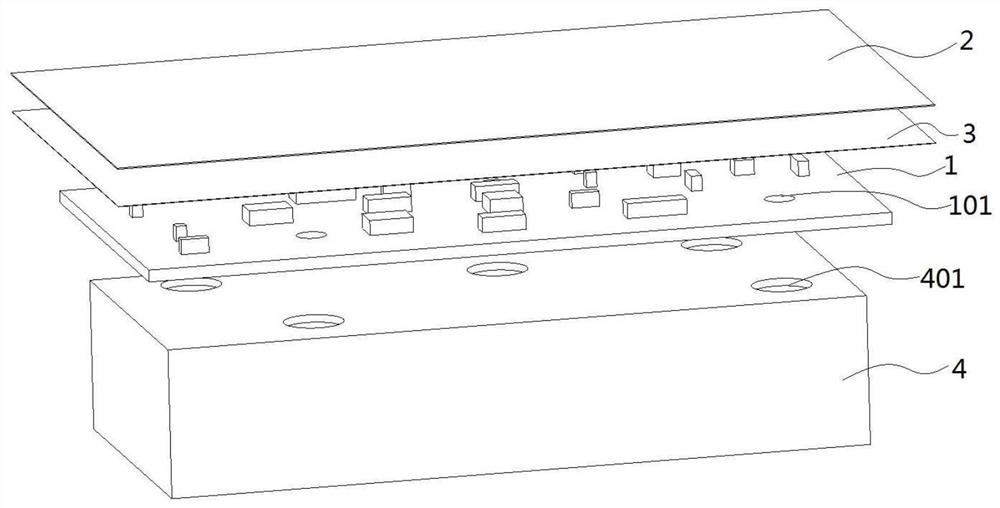

[0016] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0017] In the field of electronic equipment that outputs switch signals such as keyboards or mice, two main components are involved, namely the circuit board and the switch button. At present, one of the mainstream structures on the market is the electromechanical separation structure of the switch button and the PCB board. The switch button (that is, the mechanical switch) itself only has the function of triggering components to form a signal when it is pressed by the user, that is, the switch button itself has no inductive components and does not need to be electrically connected to the PCB board (usually a plug-in switch). Mounted or embedded on the PCB board), its function is to form a switch signal by triggering the sensing electronic components on the PCB board through the mechanical parts. The sensing electronic components inclu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com