Motor-driven telescopic hangar

A motor-driven, telescopic machine technology, used in aircraft parts, ships for aircraft, ground devices, etc., can solve the problems of increased friction between bottom pulleys and guide rails, low degree of automation, and shortened service cycles. The effect of maintenance, reducing resource pressure and reducing space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

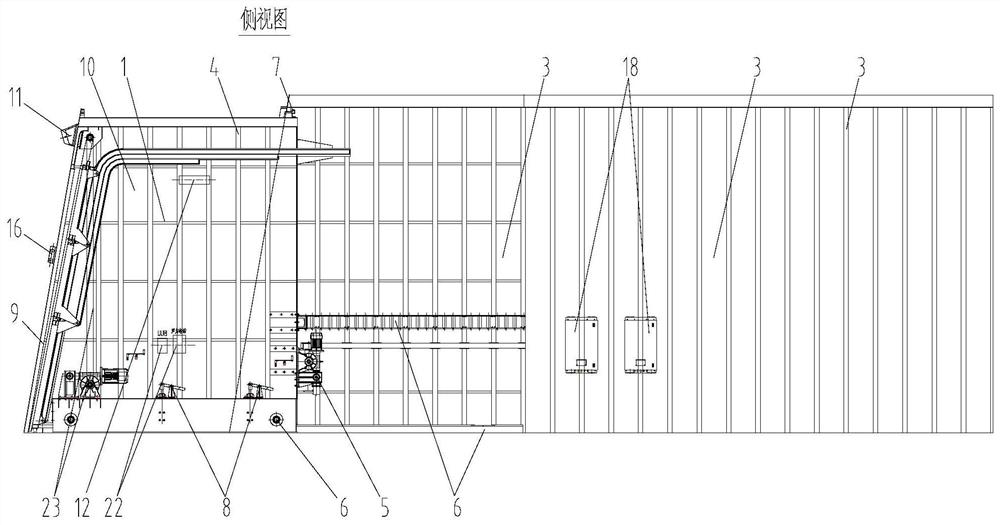

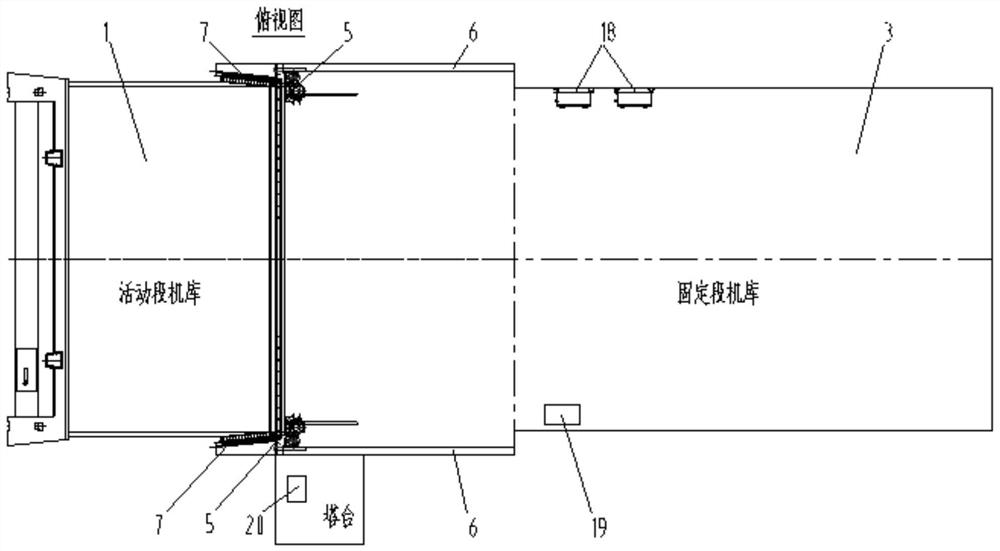

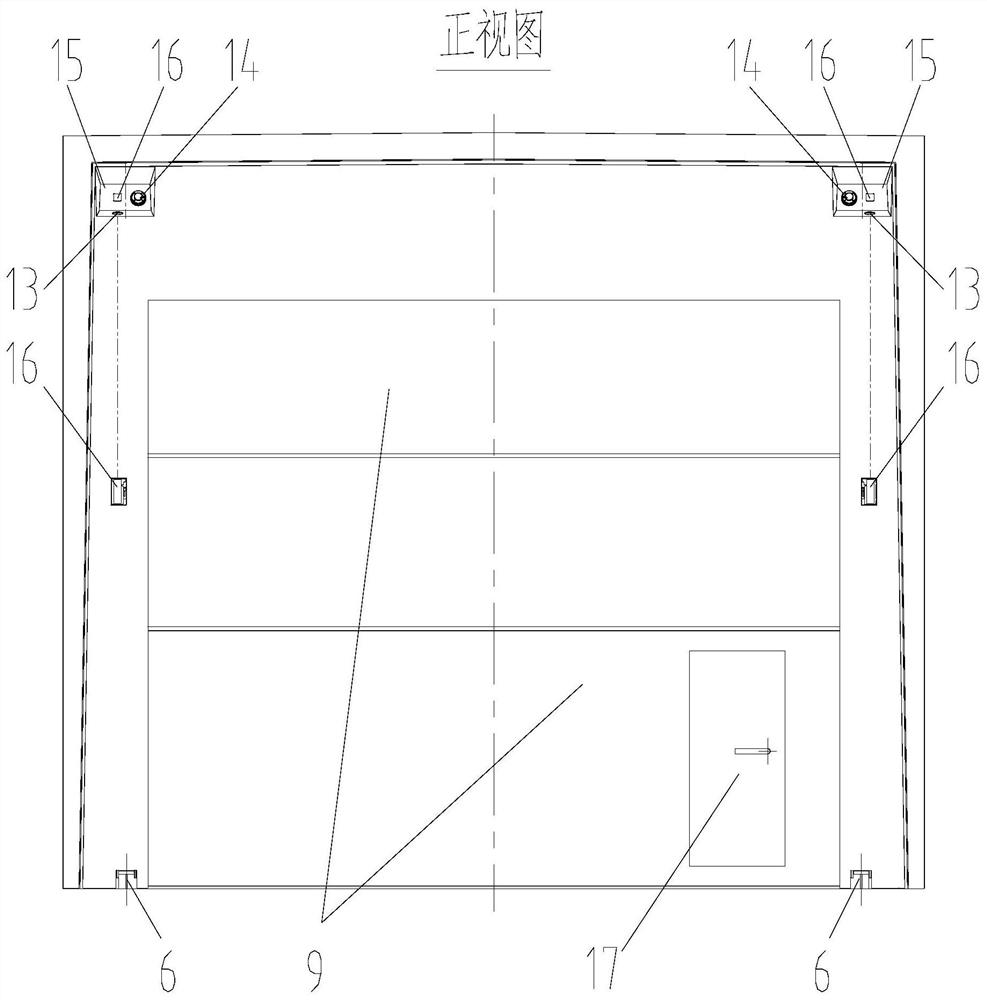

[0028] The following will combine Figure 1 ~ Figure 4 The motor-driven telescopic hangar of the present invention is further described in detail.

[0029] see Figure 1 to Figure 3 , the motor-driven telescopic hangar of the preferred embodiment of the present invention includes a movable section hangar 1, an electrical control system 2 and a fixed section hangar 3; the electrical control system 2 controls the movable section hangar 1 to extend or shrink Back to the fixed section hangar 3, and the opening and closing of the hangar door 9.

[0030] The movable section hangar 1 includes a movable section hangar main body 4, a driving device 5, a wheel-rail system 6, a fixing device 8 and a hangar door 9; in this embodiment, the movable section hangar main body 4 adopts a two-section cover Cartridge type, one end of the first sleeve is fixedly connected with the fixed section hangar 3, and the other end is slidingly connected with one end of the second sleeve, and the hangar d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com