Ferronickel refining process

A ferronickel and process technology, applied in the field of ferronickel refining process, can solve the problems of poor ferronickel effect and inability to remove impurity elements, etc., and achieve the effect of low price and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

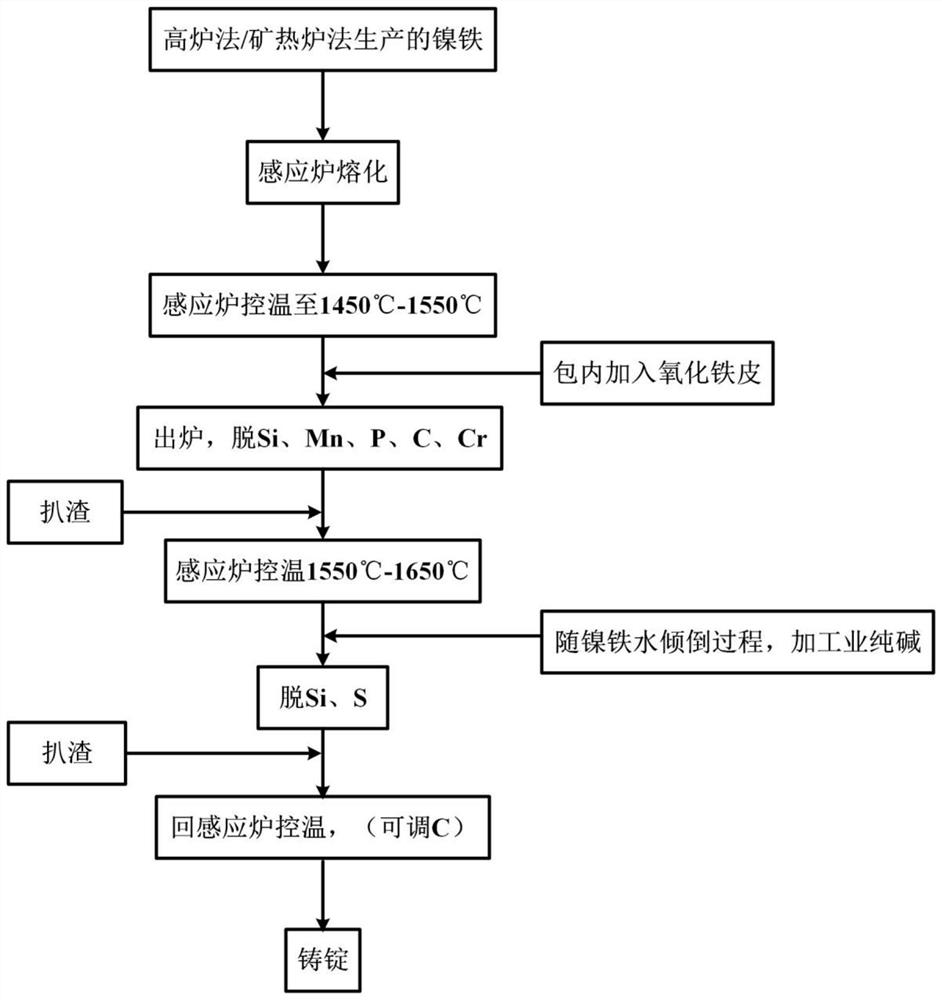

Method used

Image

Examples

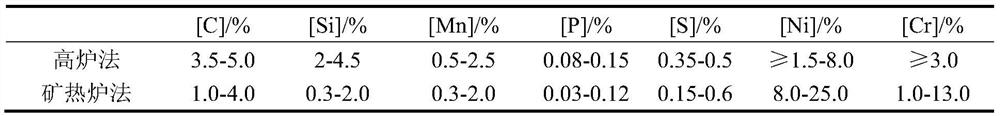

Embodiment 1

[0049] Add ferronickel smelted by blast furnace method containing 4.2%C, 3.2%Si, 0.8%Mn, 0.135%P, 0.352%S, 1.55%Ni, 4.23%Cr into the induction furnace, heat and melt, and control the temperature to 1500℃ to obtain nickel For molten iron, add 200Kg / t of iron oxide scale into the molten iron ladle, pour the molten nickel iron in the induction furnace into the molten iron ladle to remove impurities to obtain the first impurity-removed nickel-iron molten iron, and remove the slag from the first impurity-removed nickel-iron molten iron. Pour the molten nickel iron after slag removal back to the induction furnace to control the temperature to 1600°C; pour the molten nickel iron from the induction furnace into the molten iron ladle, add 25Kg / t industrial soda ash along with the iron flow, remove impurities in the nickel iron water, and obtain the first For the molten nickel-iron that has been removed for the second time, slag is removed from the molten nickel-iron that has been remove...

Embodiment 2

[0053] Add ferronickel smelted by the blast furnace method containing 4.3%C, 2.7%Si, 0.65%Mn, 0.122%P, 0.466%S, 3.82%Ni, 4.71%Cr into an induction furnace, heat and melt, and control the temperature to 1480°C to obtain nickel For molten iron, add 210Kg / t iron oxide scale into the molten iron ladle, pour the molten nickel iron in the induction furnace into the molten iron ladle to remove impurities to obtain the first impurity-removed nickel-iron molten iron, and remove the slag from the first impurity-removed nickel-iron molten iron. Pour the molten nickel iron after slag removal back to the induction furnace to control the temperature to 1580°C; pour the molten nickel iron from the induction furnace into the molten iron ladle, add 30Kg / t industrial soda ash with the iron flow to remove impurities in the nickel iron water, and obtain the first The molten nickel-iron that has been removed for the second time is slag-removed, and the molten nickel-iron after the slag removal is r...

Embodiment 3

[0057] Add ferronickel smelted by blast furnace method containing 3.9%C, 2.2%Si, 0.96%Mn, 0.093%P, 0.402%S, 6.23%Ni, 6.07%Cr into the induction furnace, heat and melt, and control the temperature to 1530℃ to obtain nickel For molten iron, add 200Kg / t of iron oxide scale into the molten iron ladle, pour the molten nickel iron in the induction furnace into the molten iron ladle to remove impurities to obtain the first impurity-removed nickel-iron molten iron, and remove the slag from the first impurity-removed nickel-iron molten iron. Pour the molten nickel iron after slag removal back to the induction furnace to control the temperature to 1620°C; pour the molten nickel iron from the induction furnace into the molten iron ladle, add 30Kg / t industrial soda ash with the iron flow to remove impurities in the nickel iron water, and obtain the first The molten nickel-iron that has been removed for the second time is slag-removed, and the molten nickel-iron after the slag removal is re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com