Cast-in-place oblique leg rigid frame bridge disc buckle type full framing and formwork construction method

A construction method and a technology of full support, which is applied to bridges, bridge parts, bridge materials, etc., can solve the problems of unclear force characteristics of the support system, frequent support accidents, and many safety hazards, so as to increase safety and reliability and ensure pouring Quality, easy processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

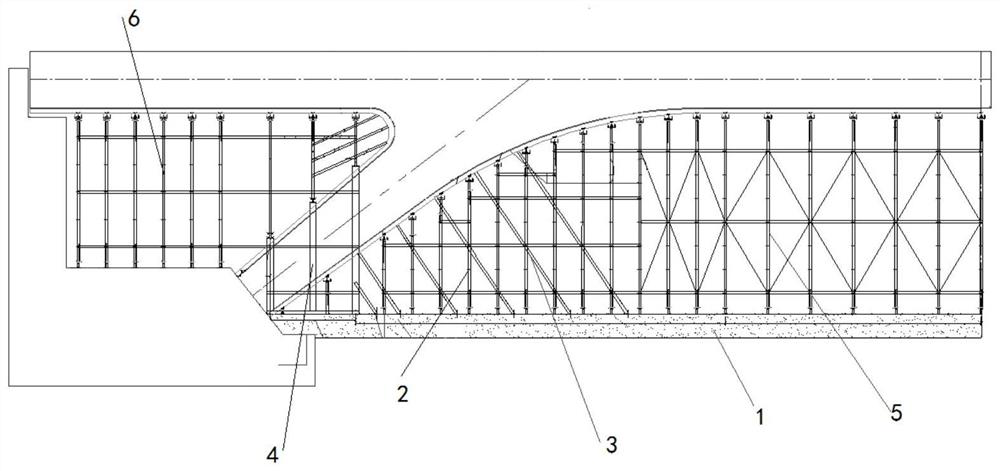

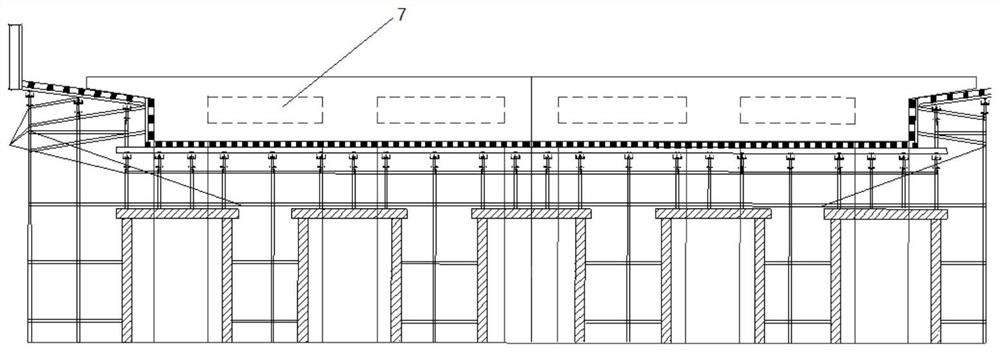

[0032] A construction method of a cast-in-place slanted-leg rigid frame bridge with a plate buckle-type full hall bracket and formwork, refer to Figure 1-2 , the construction method comprises the steps of:

[0033] S1, 1) Cofferdam diversion: Straw bag cofferdams are used to build islands in the river to avoid polluting the river. Two DN1500 reinforced concrete flat-mouth pipes are buried as diversion connecting pipes on both sides of the river. The top of the pipe is 30cm below the concrete cushion, and one The length of the diversion connecting pipe is greater than the width of the bridge and considering the requirements of the working face and transportation road, if the buried depth of the pipe top is less than 70cm, the top of the pipe needs to be reinforced with C30 reinforced concrete;

[0034] 2) Foundation treatment: dredge the river bottom within 7m of the projected surface of the bridge + the north and south sides, and backfill in layers with 132cm thick 5% cement ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com