Spiral ball speed reducer

A technology of ball reducer and helix, which is applied in transmission devices, components with teeth, friction transmission devices, etc. It can solve the problems of unavoidable backlash, large size of reducer, and accuracy error, etc., and achieve reduced friction and small size , the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The detailed content of the present invention and its specific implementation will be further described below in conjunction with the accompanying drawings.

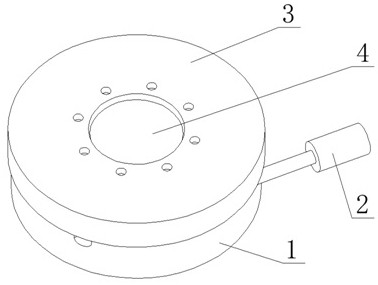

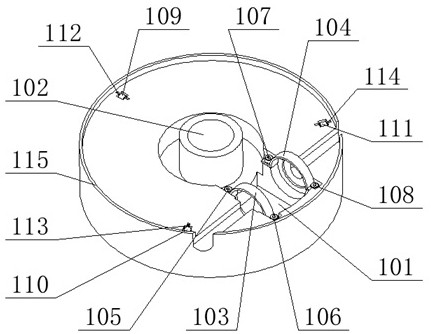

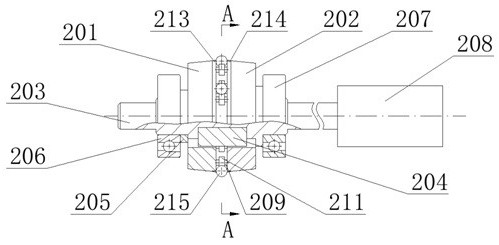

[0022] see Figure 1 to Figure 7 As shown, the helical ball reducer of the present invention includes a base 1, an input shaft assembly 2, an output shaft assembly 3, and a limit connection assembly 4. The base 1 is fixed on the ground or other fixtures, and the input shaft The assembly 2 is installed on the input shaft groove 101 of the base 1, and the output shaft assembly 3 is installed on the output shaft core 102 of the base 1. The outer surface of the power output volute 301 of the output shaft assembly 3 is smooth, and can be carried out as required. Drilling, suitable for various installation methods; the input shaft assembly 2 and the output shaft assembly 3 rely on the outer edge 115 of the base and the outer edge 303 of the output shaft assembly for radial positioning respectively, and rely on deep groo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com